Home » Products » Garage equipment » Driveshaft Repair Equipment » Welding Workbench » PRK-7

150

Maximal weight, kg

140

Maximal diameter, mm

Advanced assembly workbench for complex shaft operations

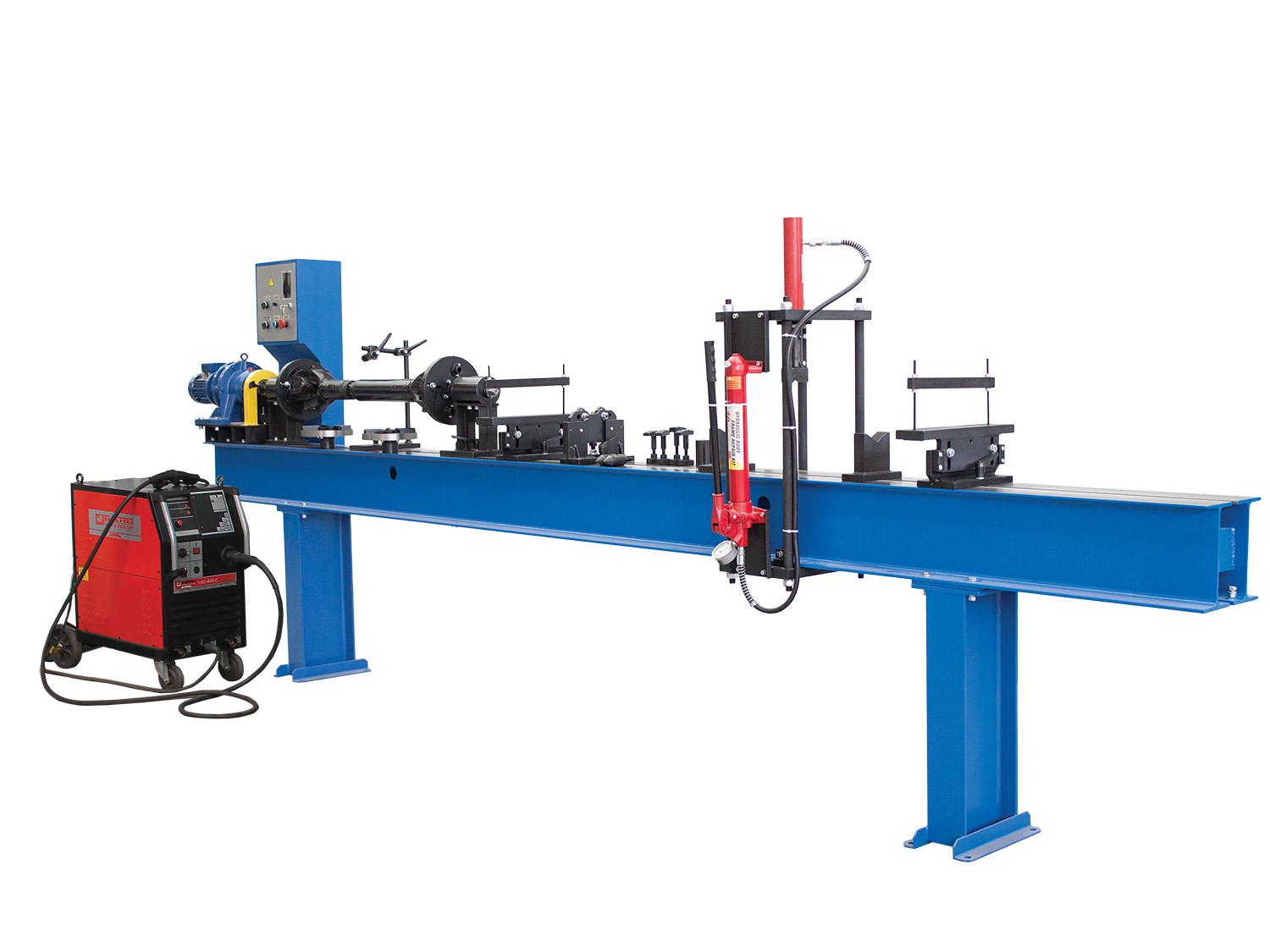

STAND PRK-7 is Designed for welding, assembly, straightening during repair and production of driveshafts.

Welding bench model PRK-7 is a device for repair of cardan shafts, which performs welding of factory quality ring seams. This equipment is adapted to work in repair shops and production facilities with serial production of products.

The stand allows, having previously set the cardan shaft with minimal runout, to weld the ring joints of the cardan gears in semi-automatic mode with constant uniform rotation and the necessary quality of penetration.

In addition, the stand has a straightening module, which allows you to adjust the curvature of the propeller shaft pipe directly on the stand.

The stand allows you to pre-position the cardan shaft with a minimum whip, weld the annular seams of cardan drives in semi-automatic mode with constant uniform rotation and the necessary quality of the penetration.

“With the help of the device, it is possible to process cardan shafts and other products, with parameters different from those presented above, if this does not interfere with comfortable work.

In addition, the stand has a straightening module, which allows you to correct the curvature of the cardan shaft tube directly on the stand.”

Multi-Function Processing Structure

- Integrated welding, assembly, and straightening platform – Comprehensive workstation combines three critical driveshaft operations in single equipment, eliminating need for multiple machines while ensuring optimal workflow efficiency.

- Precision rotary positioning system – Controlled rotation at 1.75-2.8 rpm provides constant uniform movement for consistent welding quality and penetration throughout circular seam operations.

- Extended capacity accommodation – 4900mm platform accommodates driveshafts up to 4000mm length and 150kg weight, enabling processing of heavy truck and commercial vehicle applications.

Advanced Welding Integration

- Semi-automatic and automatic welding modes – Dual operation modes provide flexibility from operator-supervised semi-automatic to fully automatic welding with automatic termination after complete revolution.

- Uniform rotation welding optimization – Controlled rotation maintains consistent welding speed enabling optimal heat input and preventing distortion while ensuring quality around entire circumference.

- Minimum runout setup capability – Precision alignment system enables driveshaft setup with minimal runout before welding, ensuring optimal quality and concentricity for balanced operation.

Integrated Straightening System - Onboard straightening press module – Integrated straightening enables curvature correction directly on stand without workpiece removal, eliminating handling between operations while maintaining alignment precision.

- Straightening prism system – Specialized prisms provide controlled support during tube straightening ensuring accurate correction while preventing surface damage and maintaining tolerances.

Versatile Mounting and Support

- Comprehensive adapter system – Complete configuration includes flange adapters up to 250mm, centers, and slotted adapters providing versatile mounting options for diverse driveshaft configurations.

- Adjustable pipe support system – Integrated support prevents sagging during operations while accommodating various lengths and weights, preserving dimensional accuracy throughout processing.

Operation and Control Features

- Single-operator functionality – Complete operations by single operator through integrated controls and automation, maximizing labor efficiency while maintaining quality standards.

- Low power consumption design – Efficient 0.18kW consumption with standard 220V single-phase supply reduces installation requirements and operating costs.

- Comprehensive accessory package – Complete set includes straightening press, adapters, centers, supports, and prisms providing immediate operational capability across applications.

|

Parameter |

Value |

|---|---|

|

Maximum mass of cardan shaft, kg |

150 |

|

Maximum cardan shaft diameter, mm |

140 |

|

Maximum cardan shaft length, mm |

4000 |

|

Rotation speed range of the part, rpm |

1.75 – 2.8 |

|

Electric motor power, kW |

0.18 |

|

Power supply parameters |

230V ± 10%, 1 Ph, 50Hz ± 1 |

|

Overall machine dimensions (length x width x height), mm |

4900 х 490 х 1770 |

|

Machine weight, kg |

600 |

Included accessories:

- Straightening press – 1 pc.

- Adapter for flanges up to 250mm – 2 pcs.

- Center – 2 pcs.

- Slotted adapter – 2 pcs.

- Adjustable pipe support – 1 pc.

- Prisms for straightening – 2 pcs.

- Instruction manual – 1 pc.

Free support and training

Request Your Custom Equipment Offer Today

Take advantage of cost savings, unmatched service, and qualification enhancement