Home » Products » Special Balancing Machine » 97VK1000

Heavy-duty driveshaft balancer up to 1000kg, large volume services

Maximal weight, kg

Maximal diameter, mm

Maximum length, mm

Balancing Machine 97VK1000 is a technically advanced solution designed specifically for engineers working at service and repair enterprises. Its primary purpose is to ensure precision and speed in the process of balancing industrial drive shafts.

Defining Initial Imbalance: At the heart of this machine is its ability to balance shafts weighing up to 1000 kg with significant initial imbalances. Thanks to its rigid construction, the 97VK1000 handles this task efficiently and flawlessly.

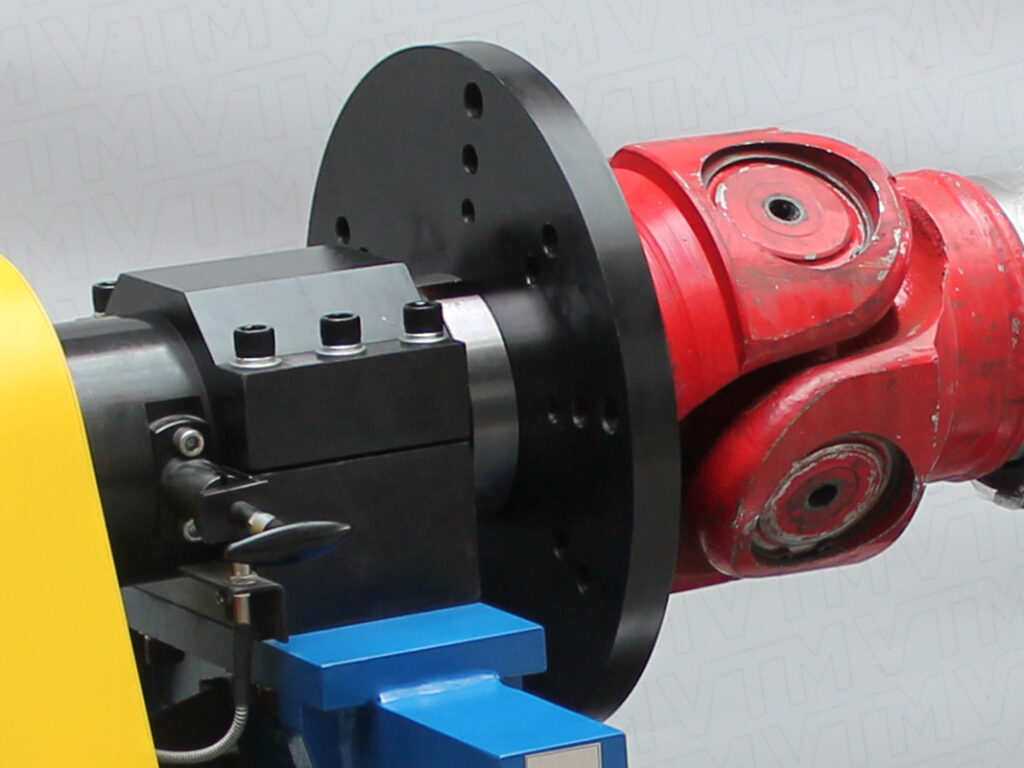

Versatility and Flexibility: One of the key advantages of this machine is its universal design and tooling. It allows workers to balance cardan shafts of various shapes and sizes, with a length of up to 4000 mm and a flange diameter of up to 400 mm. This means that the 97VK1000 can be applied in almost any situation, making it an indispensable tool on production lines.

Short Imbalance Measurement Cycle: Balancing shafts using the 97VK1000 is not only accurate but also time-efficient. The short imbalance measurement cycle enables quick equipment adjustment, reducing downtime and increasing overall enterprise productivity.

Technical Specifications: The 97VK1000 has the following technical parameters: cardan weight from 50 to 1000 kg, cardan length up to 4000 mm, and flange diameter up to 400 mm. These specifications make it an ideal choice for a wide range of industrial tasks.

Advanced Technology: The machine is equipped with an asynchronous frequency-controlled electric drive, allowing frequency adjustment without stopping the motor. This provides maximum flexibility and accuracy in adjusting the balancing process, significantly improving the quality of industrial equipment maintenance.

Convenience and Safety: The 97VK1000 machine is mounted on a standard workshop floor with a thickness of at least 250-300 mm, with subsequent anchoring to it. The presence of two screw jacks makes working on the machine convenient and safe for personnel, reducing the time for installing the balanced shaft into the machine adapters and ensuring stability during operation.

Balancing Machine 97VK1000 is a reliable partner for professionals working in the field of service and repair of industrial drive shafts. Its advanced technologies, high performance, and user-friendly design make it an indispensable tool in any manufacturing enterprise.

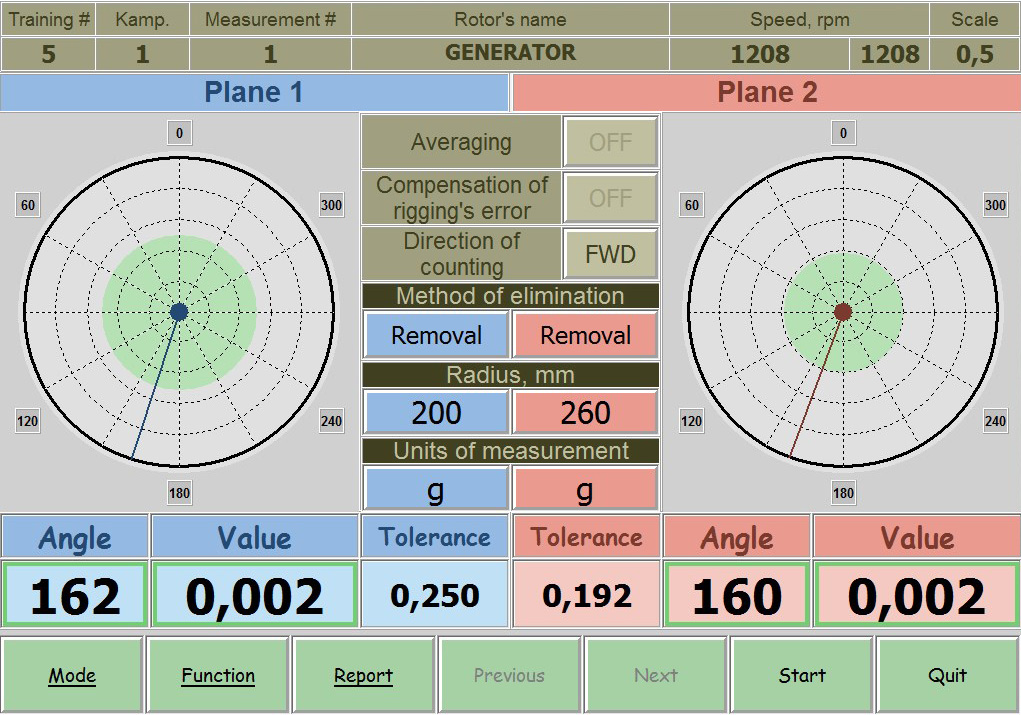

The PAK-1 unbalance measuring unit represents the latest generation of measuring complexes for dynamic balancing, combining high precision, stability, and ease of use. It’s designed to tackle a wide range of rotor balancing tasks, from simple to the most complex, requiring precise measurements.

Based on an industrial fanless computer with a touchscreen and a multi-channel measuring unit, the system ensures reliability and a long service life, even under intensive use. The PAK-1 utilizes a universal measuring path and modern component base, allowing for equally high accuracy when working with all types of rotors.

Its intuitive interface, self-calibration capability, and automation of key operations make the complex a convenient tool for both experienced specialists and beginners.

|

Parameter |

Value |

|---|---|

|

Balancing rotors weight range, kg |

50 – 1000 |

|

Maximum rotor diameter, mm |

300 |

|

Maximum flange diameter, mm |

500 |

|

Maximum cardan shaft length, mm |

4000 |

|

Machine type |

Hard-bearing |

|

Number of simultaneously measured planes |

2 |

|

Minimal achievable residual specific unbalance, gmm/kg |

10.0 |

|

Rotor rotation speed range, rpm |

200 – 1000 |

|

Drive type |

Asynchronous variable-frequency electric drive |

|

Electric motor power, kW |

7.5 |

|

Power supply parameters |

400V ± 10%, 3 Ph, 50Hz ± 1 |

|

Balancing system |

PAK-1 |

|

Overall machine dimensions (length x width x height), mm |

5000 x 900 x 1600 |

|

Machine weight, kg |

1800 |

The stand is a professional industrial solution designed to perform a full cycle of assembly and welding of heavy two-support drive shafts. It is designed for service and repair companies that specialize in maintaining industrial drive shafts.

Leave a request and our manager will contact you to answer questions via your preferred messenger.