Home » Products » Garage equipment » Turbocharger Repair Equipment » Shaft Balancing Machine » BVI-03-10T

BVI-03-10T

Balancing machine for rotors up to 3 kg. High-sensitivity soft-bearing design

3

Maximal weight, kg

400

Maximal diameter, mm

Eliminates small imbalances for turbocharger rotors

Rotor balancer model BVI-03-10 is a Soft Bearing balancing machine. It is used to balance rotors of various designs with the mass that doesn’t exceed 3 kg. The high sensitivity of the machine allows you to work with the extra small imbalance values. The main advantage of this machine is imbalance determination accuracy and high performance.

Design optimization for specialized automotive services engaged in turbocharger repair requiring high precision and productivity. The specialization ensures optimal performance for primary turbo service applications.The machine is widely used in workshops for the repair of power tools.

Due to the simplicity of design and reliability, it can be used in single or small batch production. The machine is very popular at specialized auto repair shops involved in the turbochargers repair. Due to successful design the machine has been produced for more than 20 years with minor changes.

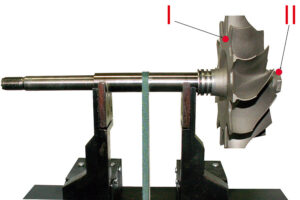

Turbocharger rotor balancing is performed in two steps:

1. Two-plane shaft balancing without compressor wheel

(I-first correction plane, II-second correction plane).

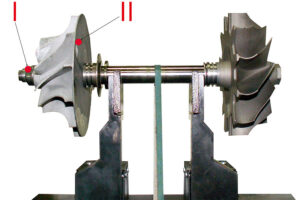

2. Two-plane balancing of the compressor wheel assembly with shaft

(I-first correction plane, II-second correction plane).

The two-stage approach ensures optimal balance for both individual components and complete assemblies.

Machine advantages:

- High measurement accuracy – 0.1 gmm/kg.

- Special prisms with antifriction material protect rotor contact surface.

- Adjustable supports accommodate different bearing journal diameters.

- Lightweight supports are easy to set relative to guides.

- Machine design accommodates rotors with closely spaced bearing journals.

- Soft supports enhance sensitivity and allow touch analysis of residual unbalance.

- Adjustable drive belt tension reduces balancing error.

- Quick rotor installation/removal with belt tension mechanism, reducing setup time.

Specialized Turbocharger Design

- Turbocharger rotor optimization – Specifically designed for turbocharger rotors up to 3kg with specialized two-stage balancing process for shaft-only and assembled configurations. The optimization ensures precise balancing for both bare shafts and complete rotor assemblies with compressor wheels.

- Ultra-compact desktop configuration – 420×400×480mm dimensions and 50kg weight enable desktop installation in specialized turbo repair facilities. The compact design maximizes workspace efficiency while providing full turbocharger balancing capability.

- High-speed capability – Extended speed range (600-3000 rpm) accommodates high-speed turbocharger rotor requirements for optimal measurement sensitivity. The elevated speed capability matches turbocharger operational characteristics for accurate balancing.

Precision Soft-Bearing System

- Ultra-high accuracy specification – 0.4 g∙mm/kg residual unbalance accuracy ensures precision balancing meeting demanding turbocharger performance requirements. The high accuracy accommodates critical turbocharger balance specifications for optimal performance and longevity.

- Soft support design for sensitivity – Soft-bearing support system maximizes measurement sensitivity enabling detection of micro-unbalances critical for turbocharger applications. The soft design provides “touch-feel” residual unbalance analysis capability for experienced operators.

- Anti-friction prism system – Specialized prisms with anti-friction material pads featuring high friction coefficient and low hardness preserve delicate turbocharger rotor surfaces. The prism design prevents wear while maintaining precise support during high-speed rotation.

Specialized Application Features

- Small journal accommodation – Support system handles rotor journals from 5-20mm diameter with adjustable height positioning for diverse turbocharger configurations. The small journal capability accommodates precision turbocharger shaft designs.

- Close center distance capability – Support design accommodates rotors with bearing centers as close as 10mm enabling balancing of compact turbocharger assemblies. The close spacing capability handles specialized turbo designs with minimal bearing separation.

- Adjustable belt tension control – Variable belt tension adjustment enables optimization for different rotor weights and configurations while reducing balancing error. The tension control provides precise rotational characteristics while enabling rapid rotor installation and removal.

- Lightweight support positioning – Low-mass support design enables easy positioning relative to guides reducing setup time and operator effort. The lightweight design improves efficiency during frequent rotor changes in service environments.

- Quick setup capability – Support adjustability and belt tension control enable rapid machine reconfiguration between different turbocharger types. The quick setup maximizes machine utilization in service environments handling diverse turbo applications.

- Single and small-scale production compatibility – Design reliability and simplicity enable use in both individual repair operations and small-scale production environments. The versatility accommodates diverse operational contexts from service to manufacturing.

Functions and features of the PB-02M balancing system:

The machine is easy to maintain and has a high repairability thanks to its design and availability of components used in the market, besides its parts are unified and used in different models of machines that is why we always have them in stock.

Calculation of the “maximum allowable imbalance” and “reference” weight will eliminate the need to do mathematical calculations;

Vector based averaging improves the balance accuracy and reduces the measuring cycle;

Graphical and numerical information display makes it easy for anyone to analyze and work;

Balance history allows a quick assessment of the balance progress by returning to the previous measurement results;

Display of acceptable imbalance allows you to instantly understand whether the imbalance of the balanced cardan is in the acceptable limits;

Intuitive interface with tips for beginners to quickly learn how to operate the machine and eliminate the possibility of committing errors.

|

Parameter |

Value |

|---|---|

|

Maximum rotor weight, kg |

3 |

|

Maximum rotor diameter, mm |

400 |

|

Distance between the centers of rotor supports, mm |

10 – 300 |

|

Maximum rotor journal diameter, mm |

20 |

|

Rotor rotation speed range, rpm |

600 – 5000 |

|

Minimal achievable residual specific unbalance, gmm/kg |

0.4 |

|

Power input, kW |

0.09 |

|

Power supply parameters |

230V ± 10%, 1 Ph, 50Hz ± 1 |

|

Balancing system |

PB-02M |

|

Overall machine dimensions (length x width x height), mm |

600 x 400 x 500 |

|

Machine weight, kg |

50 |

|

Requirements for foundation |

The machine is mounted on a standard hard floor in workshop |

- Drive belts – 1 set.

- Weight Scale – 1 pc.

- Prisms – 1 pc.

There are no options for this machine

Watch the video review of our machine

This video provides a complete overview of the machine’s design, demonstrates its main operating stages, and shows the process of setup and maintenance. You will see how the equipment operates in real conditions and assess its ease of use.

3D Visualization

Free support and training

Request Your Custom Equipment Offer Today

Take advantage of cost savings, unmatched service, and qualification enhancement