Home » Products » Special Balancing Machine » 9717K

1500

Maximal weight, kg

1350

Maximal diameter, mm

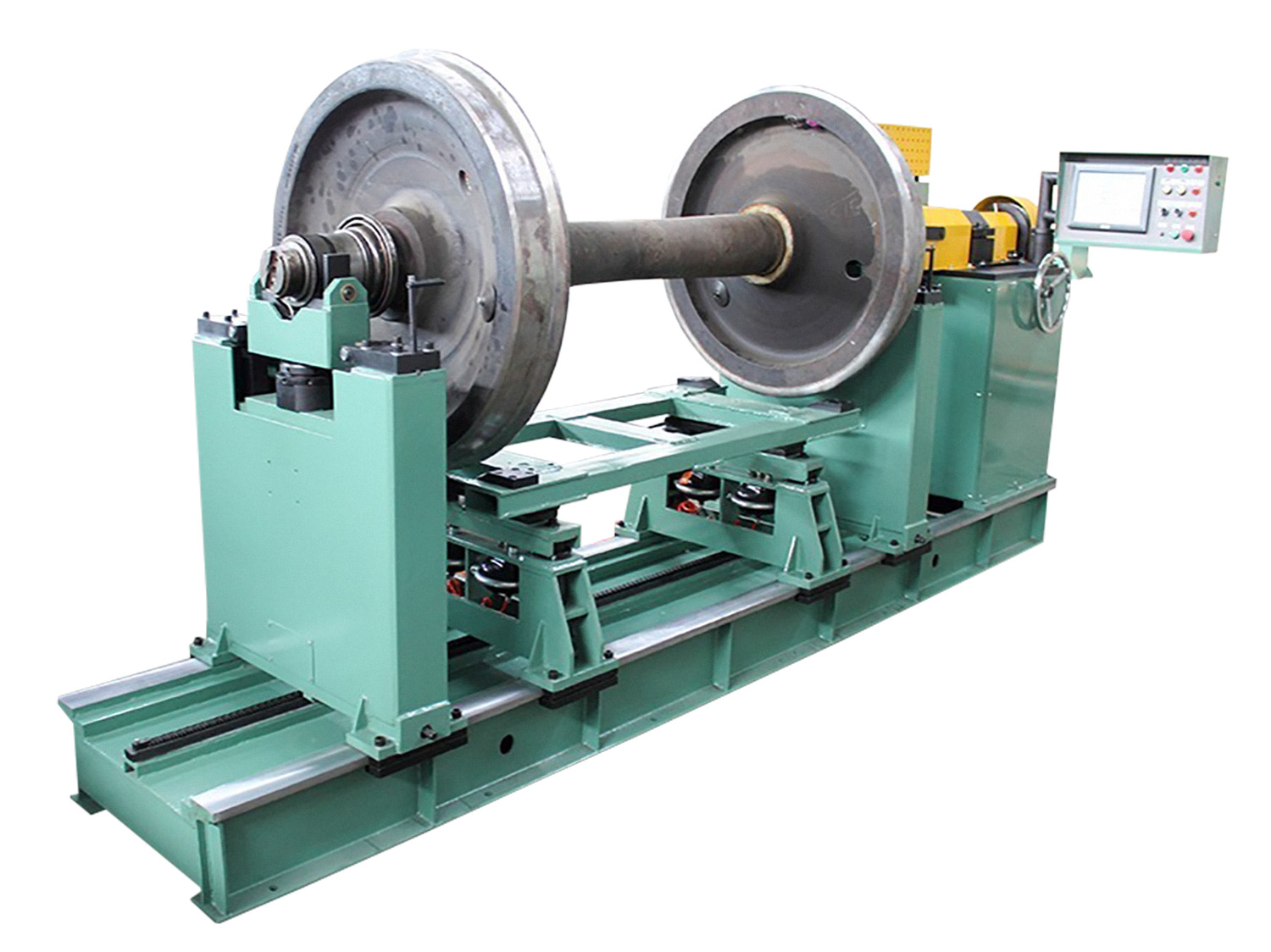

9717K machine for balancing wheel pairs of railway vehicles weighing up to 1500 kg

Wheel balancing machine model 9717K is designed for balancing of wheel pairs of railway trains weighing up to 1500 kg, including wheel pairs of passenger locomotives operating at speeds of 140 km/h.

The machine is designed for use in the repair shops of railway depots, but its modular design and high performance allow using it in small-batch production of wheelsets. The machine can be easily adapted for integration into production lines and complexes.

The machine has two vibration mounts with “pendulum” hangers and roller self-aligning blocks. It is equipped with a monolithic bed on which the supports can be moved during changeover. Control is by means of a retractable control panel including an industrial computer with touch screen and a balancing system calculation unit. Rotation is transmitted from the drive to the wheelset via a cardan gear with the use of an adapter. The electric drive has a continuously variable speed control thanks to a frequency converter.

Additional modules such as a jack, gearbox mounting bracket, wheelset run-out control and unbalance correction module can be optionally added to the machine. If required, it is possible to install a cabinet-type safety guard.

Model 9717K machine can perform the following functions:

- Dynamic two-plane balancing of wheelsets.

- Balancing of wheelsets together with a gearbox (option).

- Quality control of wheelset manufacturing and assembly.

- Quality control of wheelset balancing.

- Control of radial and axial run-out of wheels (option).

- The machine can be flexibly configured to work with different types of wheelsets, extending its functionality;

- Installation of an unbalance correction module allows to correct unbalance of the wheelset without its removal from the machine, saving time and without distracting other specialists;

- Equipment with jacks for shock-free installation of the wheelset will save the bearing surfaces for correct installation of the axlebox bearings and ensure safety of the assembly units by maintaining high accuracy of the machine for a long time. Jacks with catches provide instant alignment of the wheelset during installation;

- Installation of the “gearbox fixing bracket” on the machine makes it easy to balance wheelsets with a gearbox in the assembled state, without having to dismantle and reassemble them, which saves time;

- “Wheelset run-out measurement module” eliminates non-compliant wheelsets.

- Machine calibration takes 1 minute, is performed by the operator, provides high accuracy and saves time and money on calling a specialist;

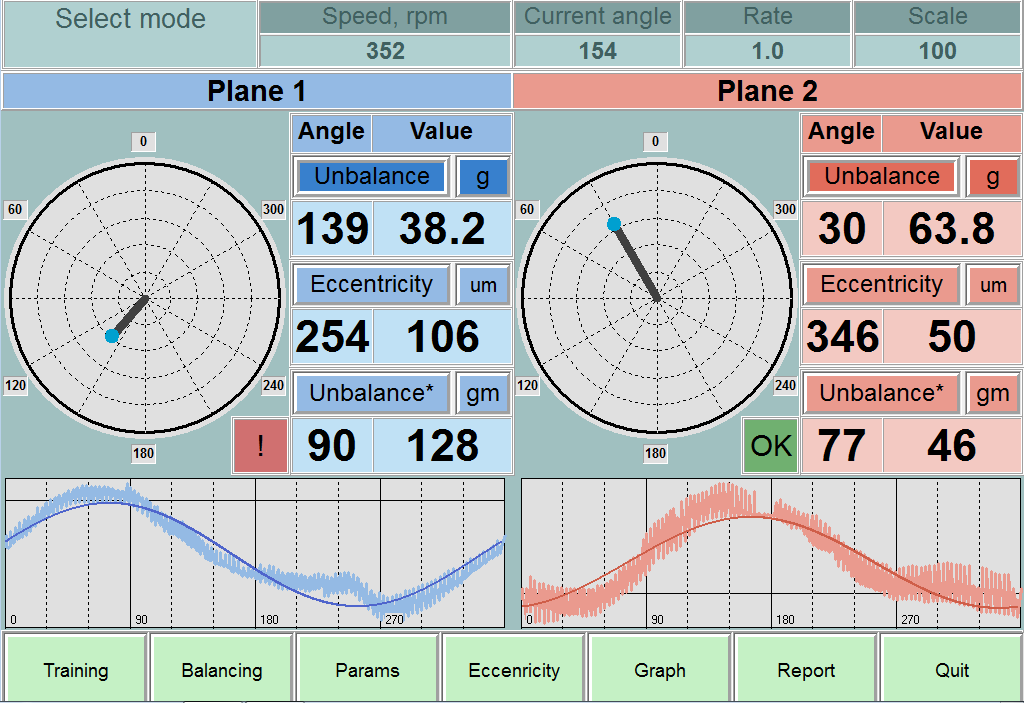

- Real-time interface shows unbalance in two planes on one screen and prompts when acceptable vibration levels are reached. This allows all users, regardless of skill level, to work efficiently;

- Measurements can be taken at low speeds (200-400 rpm), providing safety for the machine operator and others;

- Machine set-up prompts eliminate the possibility of errors made by inexperienced operators

- Storage and printing of balancing reports provides full control and documentation of the process.

Specialized Railway Application Engineering

- Dual coordinate system measurement – Provides unbalance measurement in polar coordinates across two planes with display relative to both wheel rolling geometric centers and actual axle bearing rotation axis. This dual-reference capability ensures optimal wheelset performance in real operating conditions.

- Railway-specific load handling – Engineered to accommodate wheelsets weighing 500-1500 kg with wheel diameters from 700-1350 mm and standard railway axle widths of 2000-2800 mm. The robust construction handles the demanding requirements of traction stock wheelsets while maintaining precision for lighter applications.

- Gearbox-equipped wheelset compatibility – Features special additional equipment for balancing wheelsets with integrated gearboxes driven from the middle axle section without requiring gearbox removal. This capability significantly reduces preparation time and eliminates complex disassembly procedures.

Precision Measurement & Control Systems

- Three-starts calibration method – PAK-ZhD balancing system employs advanced calibration procedure performed for each new rotor, ensuring consistently high sensitivity and measurement accuracy. This method guarantees optimal machine performance regardless of wheelset variations.

- Real-time processing and analysis – Information processing occurs in real-time mode, allowing continuous tracking of unbalance behavior and enhanced analysis capabilities. The system provides immediate feedback for faster decision-making and improved balancing efficiency.

- Dual-plane simultaneous operation – Balancing system processes two correction planes simultaneously, significantly reducing overall balancing cycle time. This parallel processing capability doubles productivity compared to sequential single-plane systems.

Advanced Mechanical Design

- Lever suspension system – Employs lever design for movable support suspension, achieving high accuracy at operating speeds of 200-400 rpm while enabling visual analysis of residual unbalance levels. The low natural resonant frequency design guarantees optimal balancing precision.

- Self-aligning roller bearings – Incorporates cylindrical hardened rollers that eliminate knurling formation on mounting journals, particularly important for low-hardness, high-mass wheelsets. The self-installation function eliminates adjustment requirements and reduces setup time.

- Pneumatic jack installation system – Equipped with specialized jacks featuring automatic centering catchers for quick, shock-free wheelset installation and removal. This system protects both wheelset bearing journals and machine support rollers from impact damage.

High-Performance Drive System

- Axial cardan drive configuration – Features full-spindle design with quill mechanism capable of transmitting high torque for rapid wheelset acceleration and deceleration. The robust drive system significantly shortens balancing cycles while increasing overall machine reliability.

- Frequency-controlled electric motor – Oversized motor with power reserve reduces acceleration/deceleration times while extending service life through reduced stress operation. The frequency converter provides electrical equipment protection and enables stepless speed regulation.

- Smooth speed transition control – Integrated frequency converter allows continuous speed adjustment without motor shutdown, optimizing balancing modes for different wheelset types. This capability ensures ideal operating conditions for each specific application.

Operator Interface & Productivity Features

- Industrial PC with touch screen – Windows OS-based system with intuitive touch interface includes comprehensive operational hints and diagnostic diagrams for rapid operator training. The visual interface simplifies information analysis and reduces learning curve requirements.

- Optional milling device integration – Machine can be equipped with additional milling equipment for direct imbalance correction, eliminating the need for external correction operations. This integrated approach streamlines the complete balancing and correction process.

- Axial and radial runout monitoring – Available sensor options provide comprehensive geometric analysis beyond standard unbalance measurement, ensuring complete wheelset quality assessment. These additional measurements support predictive maintenance and quality control protocols.

The specialized PAK-ZhD balancing system is designed for use with a horizontal balancing machine for railway wheelsets. It provides precise measurement of imbalance in the wheel planes both relative to the axis passing through the geometric centers of the wheel rolling circles and relative to the rotational axis of the wheelset. During measurement, the wheelset is mounted by the journal necks of the axle on the machine’s roller supports, ensuring accurate positioning.

The system is built on an industrial fanless computer with a touchscreen and a modern measuring unit, delivering high reliability, noise immunity, and ease of operation.

In addition to measuring the imbalance of the wheelset, the system determines the vector of eccentricity of the wheel rolling circles relative to the journal necks. After calculating the imbalance relative to the journal necks and the eccentricity, the software automatically computes the imbalance values relative to the axis passing through the geometric centers of the rolling circles.

Useful Features for Railway Wheelsets Balancing

- In Balancing mode, the system determines imbalance values relative to the rotational axis of the wheelset.

- In Eccentricity mode, it measures the displacement of the wheel rims’ centers relative to the rotational axis.

- The machine automatically switches between Balancing and Eccentricity modes during the automatic operating cycle.

- Builds a combined vector diagram of the imbalance source relative to the axis passing through the geometric centers of the rolling circles.

- Measures both axial and radial runout of the wheelset in the Runout Measurement mode.

Features of the PAK-ZhD System:

- High-precision dynamic balancing and runout measuring.

- Industrial fanless PC with touchscreen and multi-channel measuring unit.

- Three-run setup method using calibration weights.

- Operator-performed calibration, eliminating annual service costs.

- Real-time display of unbalance magnitude and angular position with correction zone highlighting.

- Output of the “Unbalance” parameter in grams, g·m, microns.

- Output of the “Eccentricity” parameter in microns

- Automatic measurement start at target speed and automatic stop upon completion.

- Generation and printing of balancing reports.

- USB ports and Ethernet interfaces for connecting external devices and network integration.

|

Parameter |

Value |

|---|---|

|

Balancing rotors weight range, kg |

500 – 1500 |

|

Maximum rotor diameter (over the bed), mm |

1350 |

|

Distance between rotor bearing journal centers, mm, min/max |

2000 – 2800 |

|

Rotor bearin journals diameter, mm |

50 – 200 |

|

Machine type |

Soft-bearing |

|

Support type |

Rollers |

|

Minimal achievable residual specific unbalance, gmm/kg |

0.4 |

|

Rotor rotation speed range, rpm |

200 – 600 |

|

Drive type |

Cardan |

|

Electric motor power, kW |

15 |

|

Power supply parameters |

400V ± 10%, 3 Ph, 50Hz ± 1 |

|

Balancing system |

PAK-ZD |

|

Overall machine dimensions (length x width x height), mm |

4000 x 1140 x 1580 |

|

Machine weight, kg |

2800 |

ADDITIONAL OPTIONS

For balancing wheelsets with a reducer in the middle of the axis, there is a jack supporting the reducer housing, and allowing to carry out balancing without disassembling the reducer housing.

Machine’s working area protective guard.

There are no options for this machine

Watch the video review of our machine

This video provides a complete overview of the machine’s design, demonstrates its main operating stages, and shows the process of setup and maintenance. You will see how the equipment operates in real conditions and assess its ease of use.

3D Visualization

Free support and training

Request Your Custom Equipment Offer Today

Take advantage of cost savings, unmatched service, and qualification enhancement