Home » Products » Garage equipment » Turbocharger Repair Equipment » Turbo Flow Bench » TURBO-BOOST-TEST

TURBO-BOOST-TEST

Dynamic turbo test bench with shaft rotation for evaluating turbocharger boost

7000+

Turbo in database

60 000

Maximum rotation speed, rpm

Complete boost diagnostics for superior repair quality

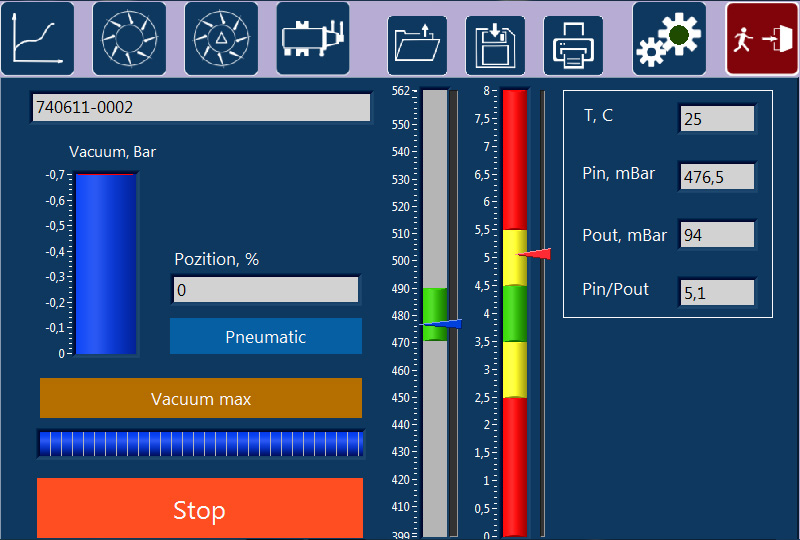

The bench is used to check the boost characteristics after a repair of a turbocharger with or without vacuum or electronic control. On the bench it is possible to adjust the geometry of the turbine in dynamic mode, when the shaft is rotating. The N75 valve check function helps find faults in the control of the turbocharger on the vehicle.

Engine repair shops can use this bench for a comprehensive evaluation of the turbocharger’s performance before installing it on an engine. The test bench can be used in turbine tuning and revamping, in the manufacture of hybrid turbines, to check changes in turbine performance after tuning.

Bench capabilities

- Real-time supercharger testing.

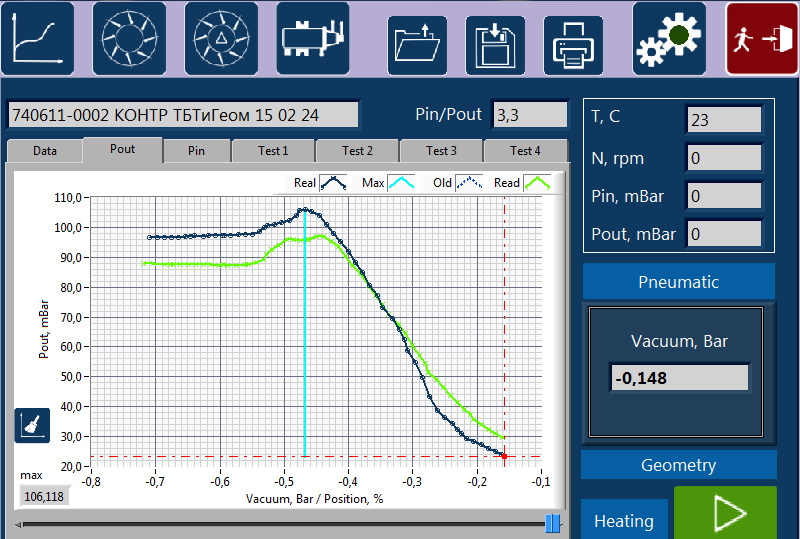

- Real-time geometry tuning.

- Checking the performance of actuators: vacuum, pneumatic and electric types.

- Diagnostics of servo drives of electric actuators (optional).

- Checking the correctness of operation of the control valve N75.

- Checking the turbocharger for oil leaks after assembly.

- Checking the turbine according to the manufacturer’s test plan.

- Calculation of turbocharger performance.

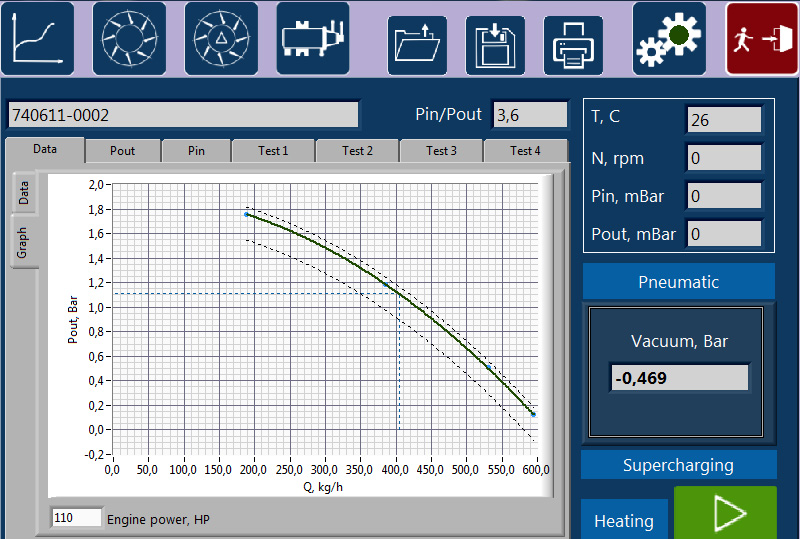

- Plotting supercharger inlet and turbocharger outlet boost vs. flow rate.

- Construction of the resulting graph.

- Creation and printing of test reports.

Advantages of the test bench

- No risks for the turbocharger

The pneumatic system of the stand is equipped with an air filter and the hydraulic system has a triple degree of oil purification. This eliminates the possibility of dirt and foreign objects entering the turbine, thus ensuring the safety of the turbocharger during testing. - Ergonomics

The spacious working area allows you to work comfortably with turbochargers of any design.

The touch screen and intuitive software interface allow you to quickly learn how to operate the bench. - Versatility

The universal design of the stand allows working with turbochargers of trucks and cars with engine displacement not exceeding 3 liters.

Mechanical Design

- Compact Bench Construction – The frame is built for stability and vibration resistance, allowing reliable operation on a standard workshop floor without special foundation.

- Integrated Oil Circuit – Includes a 12-liter oil tank with heating and circulation system, ensuring proper lubrication and leak detection during tests.

- Universal Mounting System – A complete adapter kit enables installation of turbochargers of various designs, simplifying setup and reducing downtime.

Drive and Flow Systems

- High-Performance Vortex Compressor – Delivers airflow up to 110 m³/min at pressures up to 900 mbar, simulating engine-like operating conditions.

- Vacuum Generation System – Capable of creating up to –800 mbar for precise actuator testing and geometry control across the full operating range.

- Rotor Drive Capability – Supports turbocharger rotor speeds up to 50,000 rpm, allowing realistic performance simulation.

Measurement and Control Systems

- Real-Time Geometry Calibration – Measures and visualizes vane position and performance throughout the entire operating range.

- Multi-Sensor Monitoring – Tracks boost pressure, flow rates, oil pressure, and leakage conditions to provide a complete diagnostic picture.

- Backlash and Wear Assessment – Enables detection of play in the geometry mechanism, supporting preventive maintenance decisions.

Electronics and Software

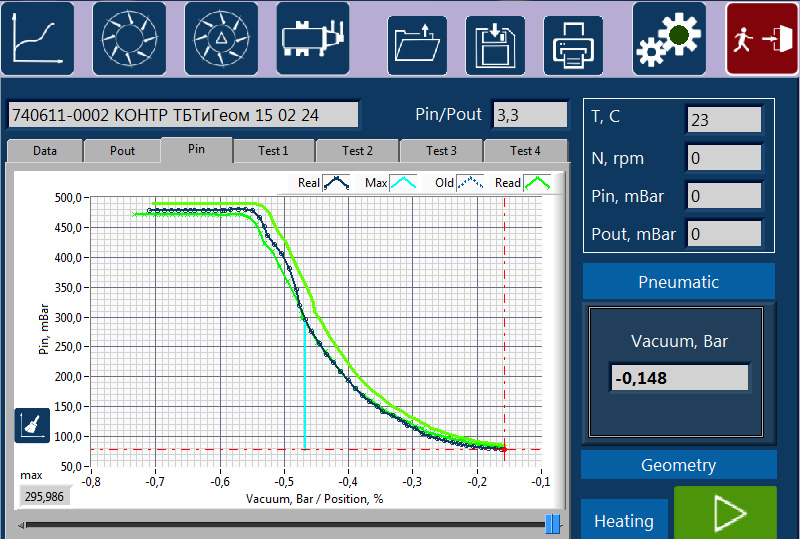

- Dedicated Control Software – Runs advanced algorithms to calculate performance parameters and automatically generate diagnostic graphs.

- Graphical Analysis Tools – Simultaneously displays actual test data and reference curves, helping engineers quickly compare results with manufacturer specifications.

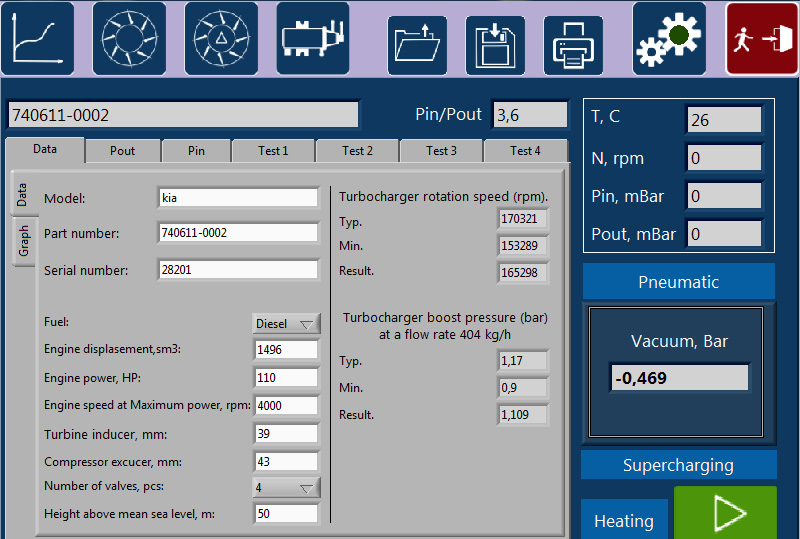

- Extensive Database – Includes over 7,000 test plans, expandable by the operator, ensuring compatibility with almost all standard turbocharger models.

Utility and Installation Requirements

- Single Power Supply – Operates only from a 380V / 50Hz mains connection, with no additional utilities such as compressed air required.

- Workshop-Ready Design – Compact footprint (1330 × 770 × 1440 mm) and weight of approx. 250 kg allow easy placement in standard service environments.

Data Acquisition and Visualization

- Automatic Graph Generation – During each test, the software plots graphs of boost pressure versus inlet and outlet flow rates, ensuring precise visualization of turbocharger performance.

- Reference Curve Comparison – Displays both actual measurements and predefined reference graphs, allowing quick detection of deviations from manufacturer specifications.

- Multi-Test Overlay – Stores and overlays results from multiple test runs, giving engineers a clear picture of changes in performance over time.

Diagnostic Functions

- Geometry Performance Mapping – Provides full-range analysis of variable geometry function in dynamic mode, identifying issues with vane movement or response.

- Actuator Evaluation – Supports testing of vacuum, pneumatic, and electronic actuators, with optional modules for servo-drive diagnostics.

- Control Valve Verification – Includes functionality to test N75 valve operation across the entire vacuum range, confirming proper regulation.

Database and Test Plans

- Extensive Test Plan Library – Contains more than 7,000 ready-made turbocharger test plans, covering nearly all common models in the market.

- Expandable Database – Operators can create and add custom test plans, ensuring adaptability for new or less common turbochargers.

- Manufacturer-Specific Testing – Enables testing procedures to be carried out according to OEM test plans, supporting accurate and standardized diagnostics.

Reporting and Documentation

- Comprehensive Test Reports – Automatically generates reports for each diagnostic session, including graphs, measured parameters, and calculated performance values.

- Export and Storage Options – Results can be saved, archived, and shared, providing reliable documentation for workshop records and customer reporting.

|

Parameter |

Value |

|---|---|

|

Maximum achievable rotor rotation frequency, rpm |

60000 |

|

Maximum air flow rate of the vortex compressor, m3/min |

110 |

|

Maximum pressure of the vortex compressor, mbar |

900 |

|

Maximum vacuum created by the vacuum pump, mbar |

-800 |

|

Power input, kW |

6 |

|

Power supply parameters |

400V ± 10%, 3 Ph, 50Hz ± 1 |

|

Overall machine dimensions (length x width x height), mm |

1330 х 770 х 1440 |

|

Machine weight, kg |

250 |

|

Requirements for foundation |

The machine is mounted on a standard hard floor in workshop |

The equipment supplied with the machine allows you to install almost the entire range of turbines from modern manufacturers.

Watch the video review of our machine

This video provides a complete overview of the machine’s design, demonstrates its main operating stages, and shows the process of setup and maintenance. You will see how the equipment operates in real conditions and assess its ease of use.

3D Visualization

Free support and training

Request Your Custom Equipment Offer Today

Take advantage of cost savings, unmatched service, and qualification enhancement