Home » Products » Garage equipment » Turbocharger Repair Equipment » Actuator Tester » ATP-3000

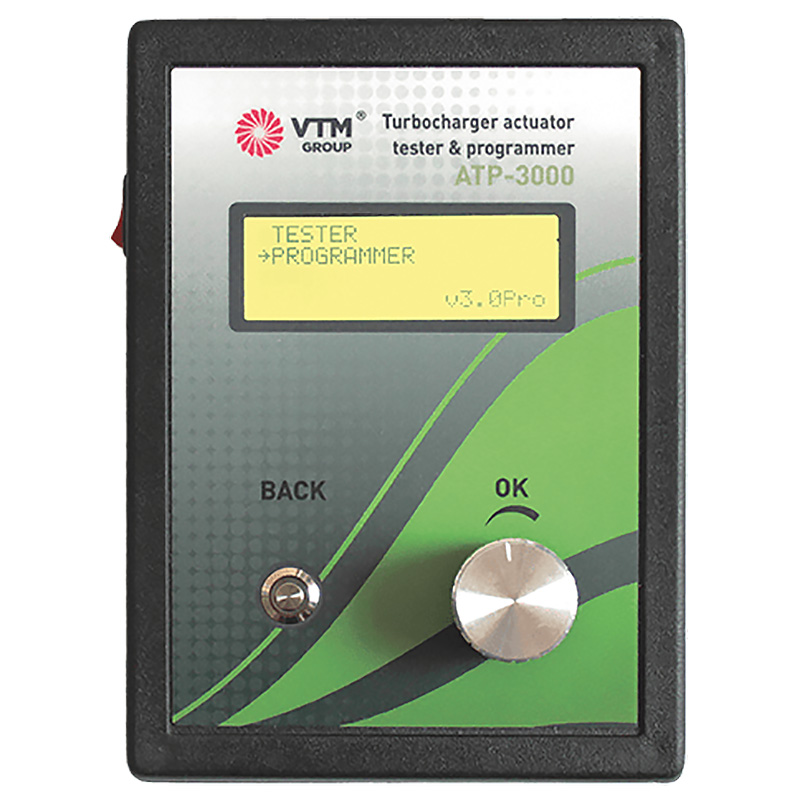

ATP-3000

Tester-programmer for electronic actuators with firmware save/load functions

18

Diagnostic cabels

9

Additional cables

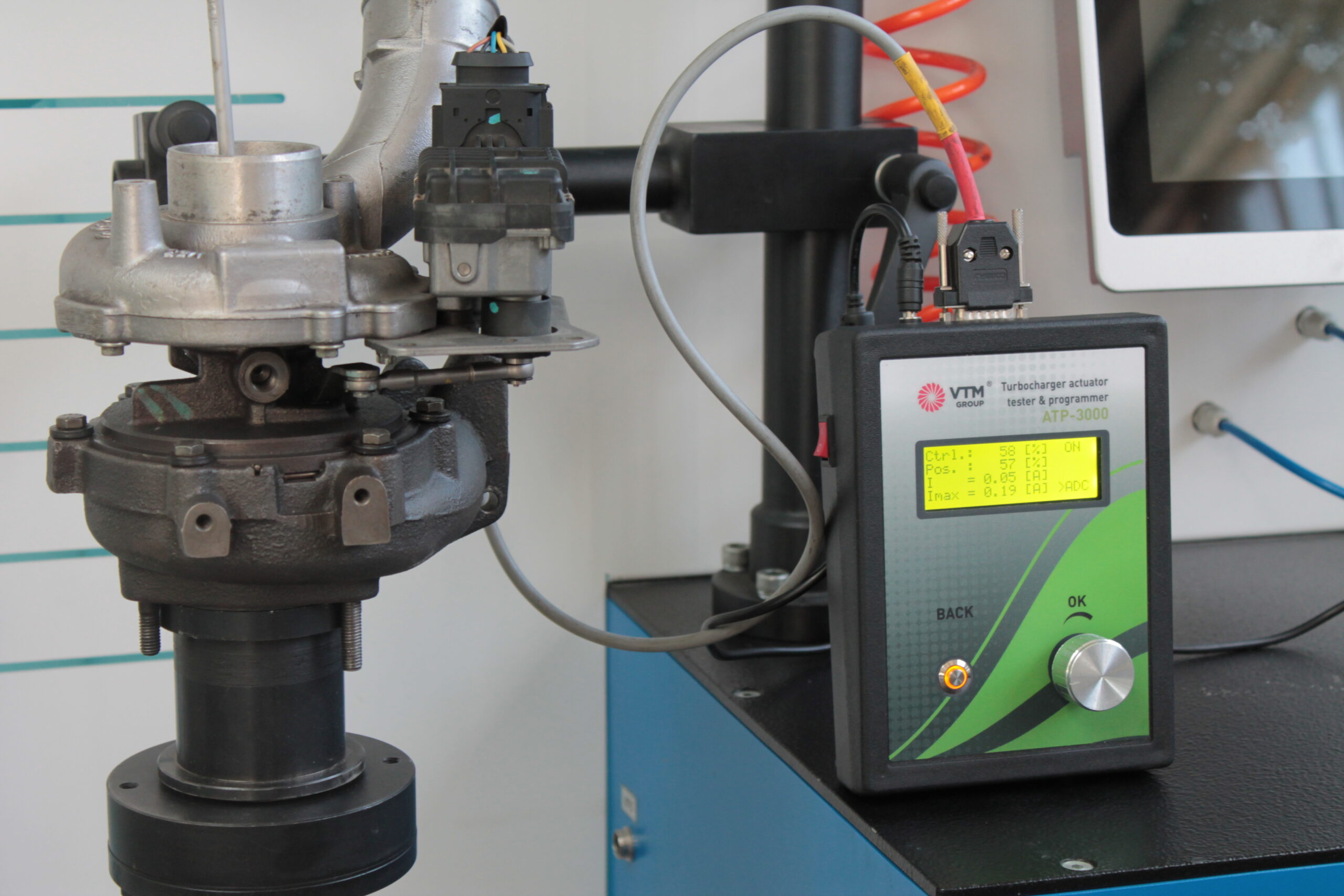

Universal tool for turbo diagnostics with electronic control

The ATP-3000 tester-programmer is an instrument for diagnostics of electronic actuators controlling regulated turbines with electric drive. It checks operability of the electric actuator as a whole and its separate elements, such as electric actuator and servomotor. The individual diagnostics of each element allows to determine precisely the condition of the turbocharger drive and detect problems, if they exist.

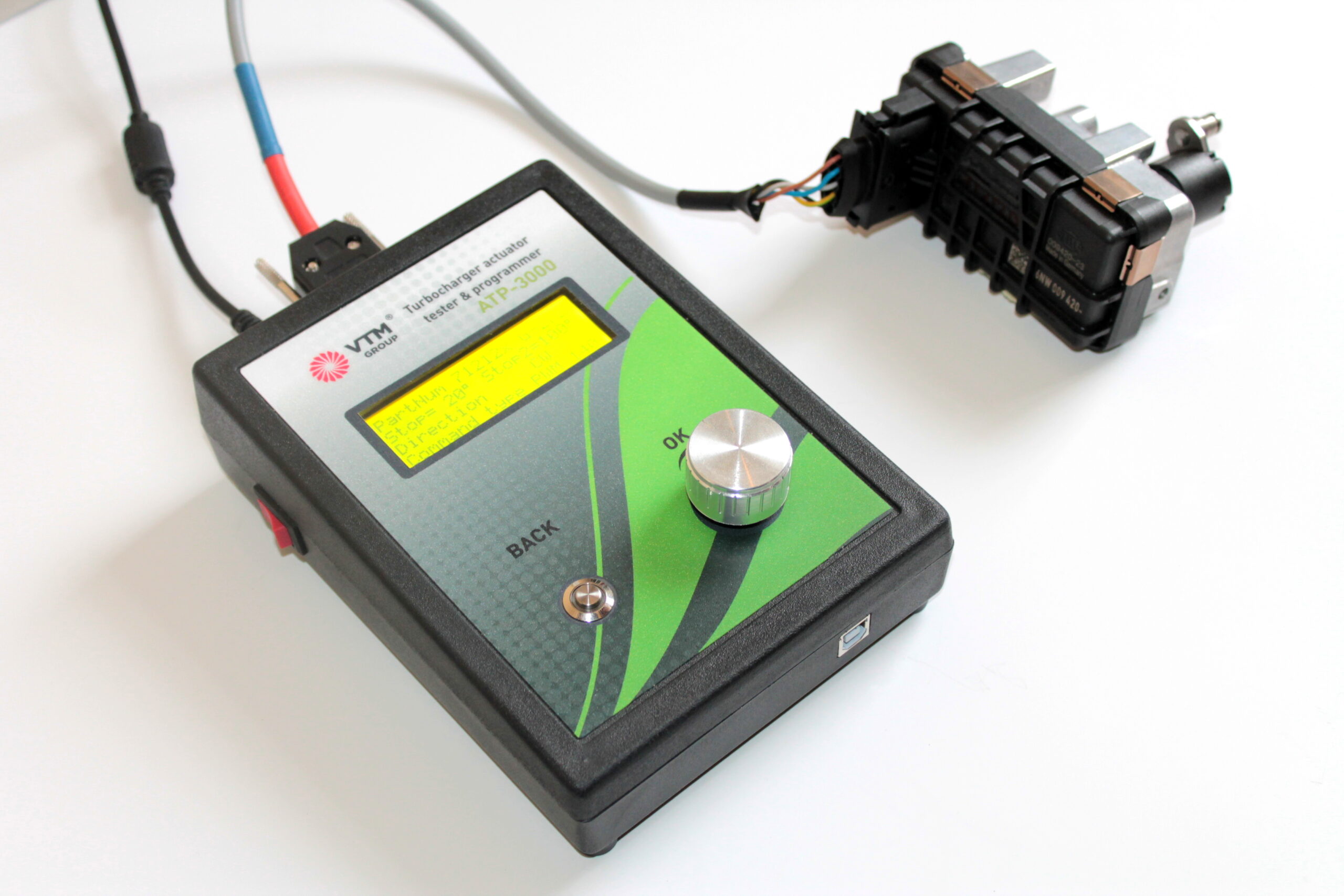

The device is based on microprocessor technology. Sealed housing made of impact-resistant plastic for operation in any environment. Two elements control: a button and a regulator. Liquid crystal screen is used to display information. Powered by standard laptop power supply. Connection to electric actuators with cables and adapters included in the delivery set.

Functions

Testing- Testing of electronic turbocharger drives;

- Diagnosis of DC motors from 12 V to 2 A;

- Verification of supercharger solenoids used in pneumatic systems;

- Electronic and pneumatic actuator position sensors check according to protocol: PWM, ADC, SENT.

- Programming (adaptation) of electronic HELLA REA actuators:

- Saving the actuator firmware file in the instrument memory (up to 99 pcs.).

- Saving the actuator firmware files on a PC (no restrictions).

- Loading firmware from the PC into the actuator with the instrument. device.

- It is possible to copy settings between between actuators.

- Programming (adaptation) of electronic SIEMENS actuators

- Automatic detection of DC motor polarity inside the actuator;

- 2A current protection for 3 seconds;

- Displaying of the position transmitter readings as a percentage; Displaying of the position sensor readings as a percentage;

- Displaying of the readings of the position sensors as a percentage;

- Output of additional parameters of programmable HELLA actuators:

- Firmware number;

- The value of the programmed angles;

- Communication protocols:

- PWM

- CAN

- ADC

- SENT

- Programming actuator angles HELLA REA

Car actuators

HELLA

6NW‑008‑091, 6NW‑008‑412, 6NW‑009‑206, 6NW‑009‑228, 6NW‑009‑420, 6NW‑009‑483, 6NW‑009‑543, 6NW‑009‑550, 6NW‑009‑660, 6NW‑010‑099‑01, 6NW‑010‑099‑02, 6NW‑010‑099‑03, 6NW‑010‑099‑05, 6NW‑010‑099‑07, 6NW‑010‑099‑08, 6NW‑010‑099‑21, 6NW‑010‑430‑00, 6NW‑010‑430‑01, 6NW‑010‑430‑03, 6NW‑010‑430‑04, 6NW‑010‑430‑22, 6NW‑011‑132‑62

MITSUBISHI

49335‑002xx, 49335‑004xx, 49135‑056xx, 49135‑057xx, 49135‑058xx, 49477‑01012, 49477‑01104, 49477‑01202, 49477‑01203, 49477‑01204, 49490‑93501

SONCEBOZ

5304‑9xx‑0065, 5304‑9xx‑0069, 5304‑9xx‑0073, 5304‑9xx‑0115, 5439‑9xx‑0061, 5439‑9xx‑0062, 5439‑9xx‑0063, 5439‑9xx‑0064, 5439‑9xx‑0110, 5439‑9xx‑0111, 5439‑9xx‑0112, 5439‑9xx‑0113, 5900‑110‑7019

DENSO

780709‑xxxx, 780708‑xxxx, 17201‑30100, 17201‑30101, 17201‑30110, 17201‑30160, 17201‑301xx

MAHLE

everything

SIEMENS

everything

HITACHI

5304‑970‑0062, 5304‑988‑0062

Torque motor

5900‑110‑7349, 5900‑110‑7304

BorgWarner

5900‑110‑7382, 5900‑110‑7267

Honeywell

835556‑0062, 842232‑0039

Others

K6T55273, K6T60572, and similar in principle of action.

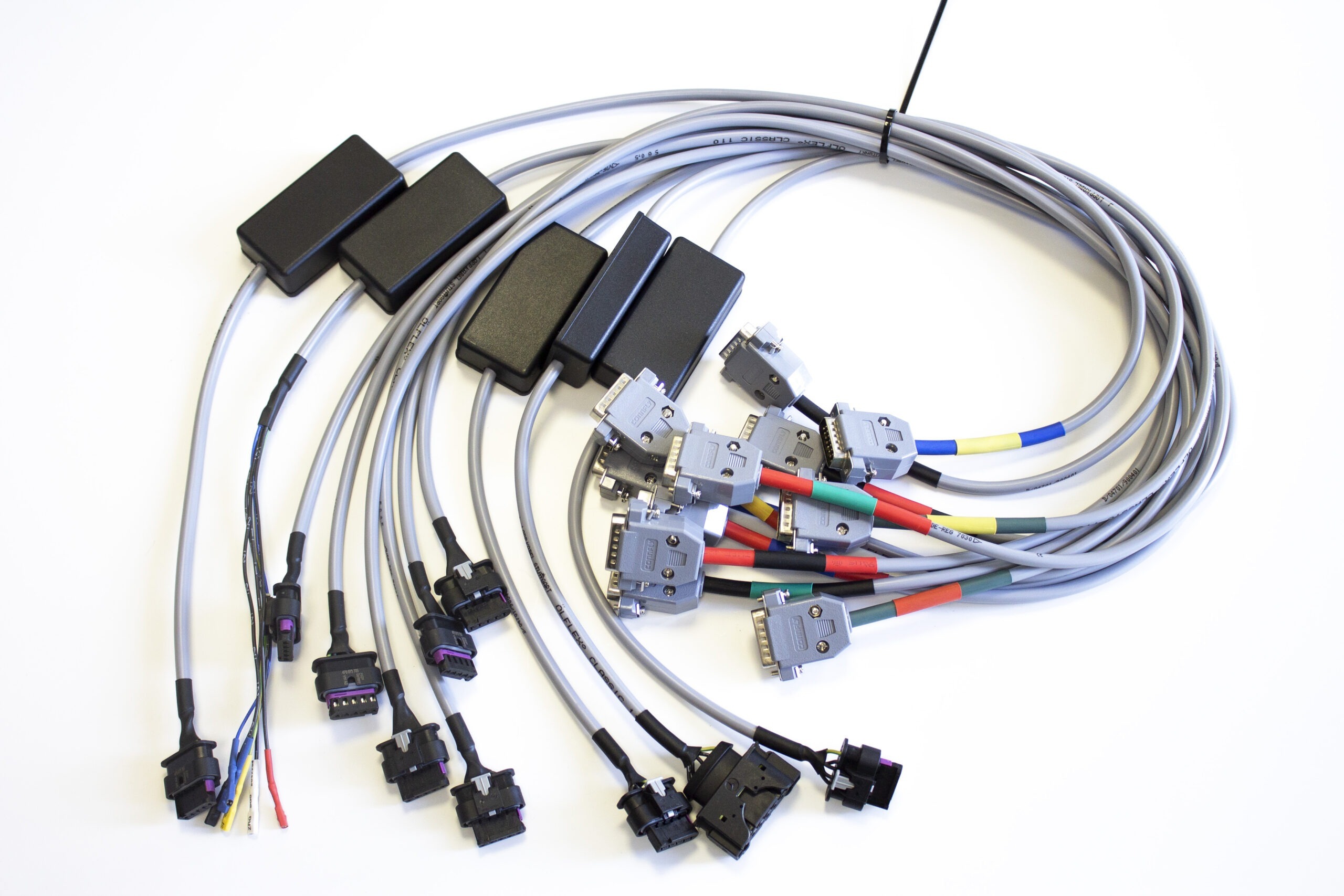

Supplied with:

- A set of cables for diagnostics of drives – 12 pcs.

- Set of cables for diagnostics of position sensors – 6 pcs.

- Set of additional diagnostic cables for uncommon turbo – 9 pcs. *

- USB cable – 1 pc.

- Standard power supply AC / DC 12V, 4A.

* The basic delivery set is not included. You can purchase additionally if necessary.

Watch the video review of our machine

This video provides a complete overview of the machine’s design, demonstrates its main operating stages, and shows the process of setup and maintenance. You will see how the equipment operates in real conditions and assess its ease of use.

Free support and training

Request Your Custom Equipment Offer Today

Take advantage of cost savings, unmatched service, and qualification enhancement