Home » Products » Garage equipment » Turbocharger Repair Equipment » Turbo Flow Bench » GEOMET-500

GEOMET-500

Compact VNT turbo flowbench, quickly restores factory settings after a core replacement

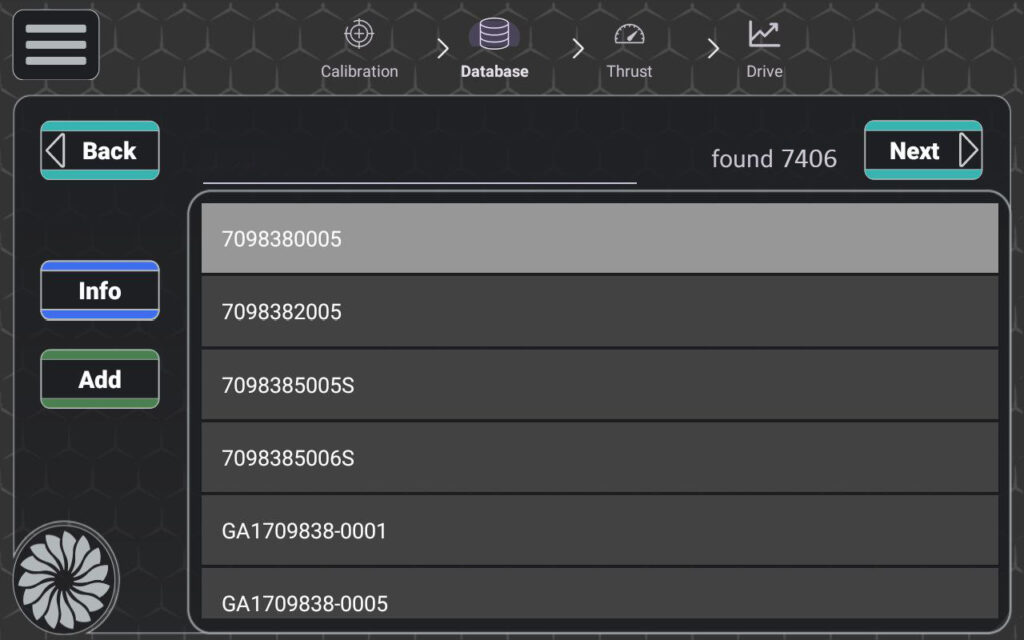

7000+

Turbo in database

Static

Test bench

Affordable and simple VNT calibration for small workshops

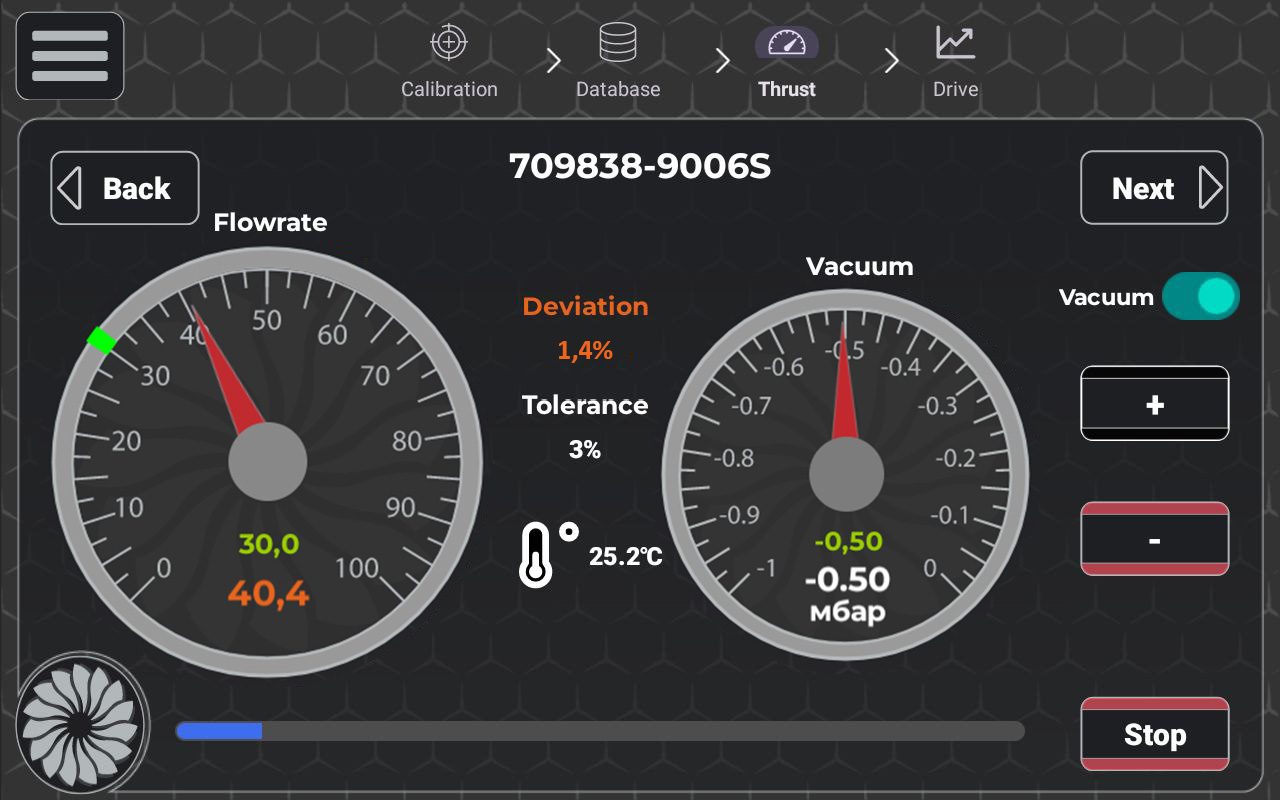

“Geomet-500” is a bench for adjustment of turbochargers with variable geometry: fast-payback equipment that allows to effectively restore turbocharger settings to factory standards after cartridge or actuator replacement. The equipment reduces turbine tuning time and improves the quality of repairs, creating a comfortable and safe working environment.

On the stand it is easy to adjust the extreme position of the blades of the nozzle apparatus, thus getting rid of the effect of “foreblow” or “underblow”, detrimental to the performance of the car. In addition, it is possible to adjust the length of the actuator rod to set the moment of operation of the air flow control mechanism.

- Modest price and high performance.

- High efficiency – set-up cycle takes less than 5 minutes.

- No oil system – no monthly maintenance costs.

- Own compressor – autonomy of equipment and reliability of measurements.

- Open working area – work with any (even oversized) turbochargers.

- Vertical installation – easy access to the turbine during adjustment.

- Sophisticated mounting system – magnetic adapter reduces turbine installation to 10 sec. and the process shoulder allows operation with non-magnetic housings.

- High versatility – work with vacuum, pneumatic drives.

Diagnostics of electrically driven turbines – the diagnostic function is available when the stand is used together with the ATP-1000 or ATP-3000 actuator tester. - N75 valve diagnostics – simplifies analysis of vehicle turbo system failures.

- Calibration by the stand operator – high accuracy of measurements without spending resources on calling specialists.

- The bench is calibrated in 10 seconds.

- Air filtration system – ensures turbocharger safety.

- Affordable quality components – quick repair, no unplanned component costs.

- Complete set of adapters – all adapters required for operation are included. The design of the adapters allows you to make them yourself if necessary.

Mechanical Design

-

Open work area provides easy access to the turbocharger, including oversized units, ensuring operator convenience during setup and adjustment.

-

Universal mounting system with magnetic adapter reduces installation time to just a few seconds, while a support flange allows operation with non-magnetic housings.

-

Compact and ergonomic frame layout ensures comfortable operation and optimal use of workshop space.

Air Supply and Filtration

-

Built-in vortex compressor delivers autonomous air supply, eliminating the need for connection to an external pneumatic system.

-

Integrated air filtration system protects the flow meter from contamination, maintaining measurement accuracy and extending service life.

Drive and Control Systems

-

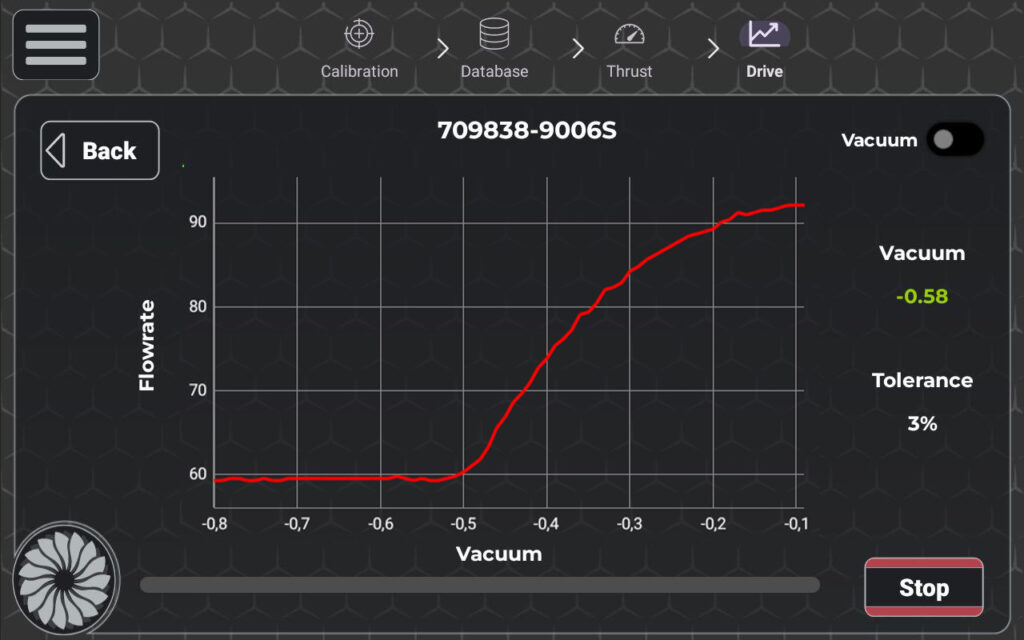

Adjustable geometry mechanism enables precise calibration of extreme vane positions, eliminating both underboost and overboost errors.

-

Actuator rod length can be fine-tuned directly on the stand, ensuring compatibility with a wide range of turbocharger models.

-

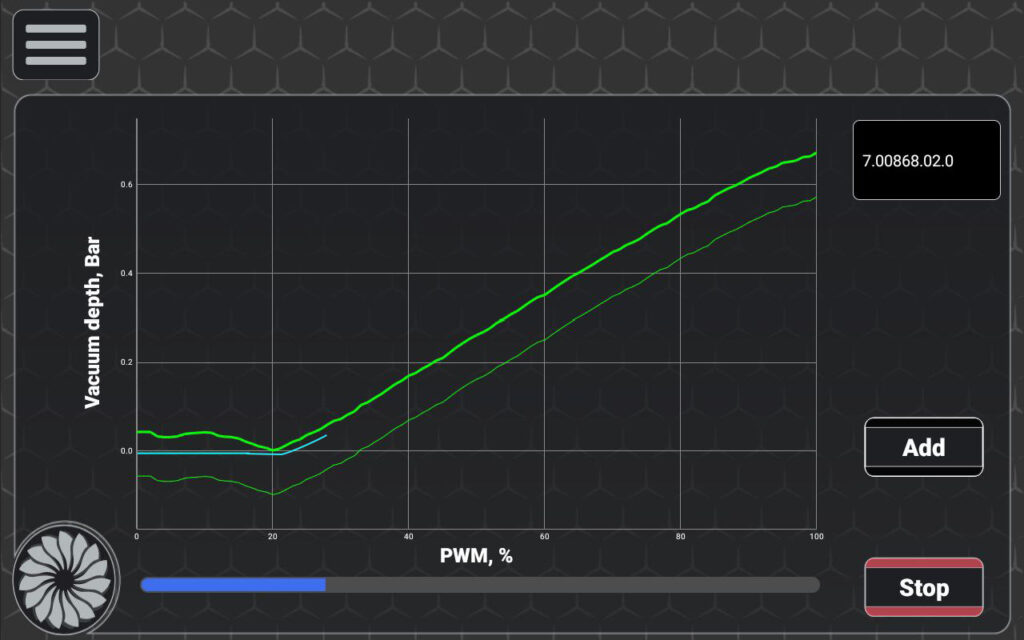

Operator calibration function allows the system to be recalibrated within seconds, without the need for external specialists.

Diagnostics and Compatibility

-

Stand supports diagnostics of turbochargers equipped with electronic actuators when used together with actuator testers (ATP-1000 or ATP-3000).

-

N75 valve diagnostic function simplifies fault detection in vehicle boost control systems.

-

Full set of adapters supplied with the unit covers most turbocharger types, with the possibility of custom-made adapters if required.

Reliability and Usability

-

The bench maintains stable performance even under fluctuations in temperature, humidity, or power supply interruptions, ensuring reliability in workshop conditions.

-

Simple structural design and use of standard consumables (filters) make the system easy to maintain with readily available components.

measuring system Geomet-500

|

Parameter |

Value |

|---|---|

|

Maximum air flow rate of the vortex compressor, m3/min |

180 |

|

Maximum vacuum created by the vacuum pump, mbar |

-700 |

|

Power input, kW |

1.5 |

|

Power supply parameters |

230V ± 10%, 1 Ph, 50Hz ± 1 |

|

Overall machine dimensions (length x width x height), mm |

1100 x 520 x 1450 |

|

Machine weight, kg |

160 |

|

Requirements for foundation |

The machine is mounted on a standard hard floor in workshop |

- Set of adapters for installation of turbines – 1 set

- Digital indicator for measuring the rod stroke – 1 set

- Operation manual – 1 pc

Watch the video review of our machine

This video provides a complete overview of the machine’s design, demonstrates its main operating stages, and shows the process of setup and maintenance. You will see how the equipment operates in real conditions and assess its ease of use.

Free support and training

Request Your Custom Equipment Offer Today

Take advantage of cost savings, unmatched service, and qualification enhancement