Home » Products » Garage equipment » Driveshaft Repair Equipment » Driveshaft U-joint Press » P1515K

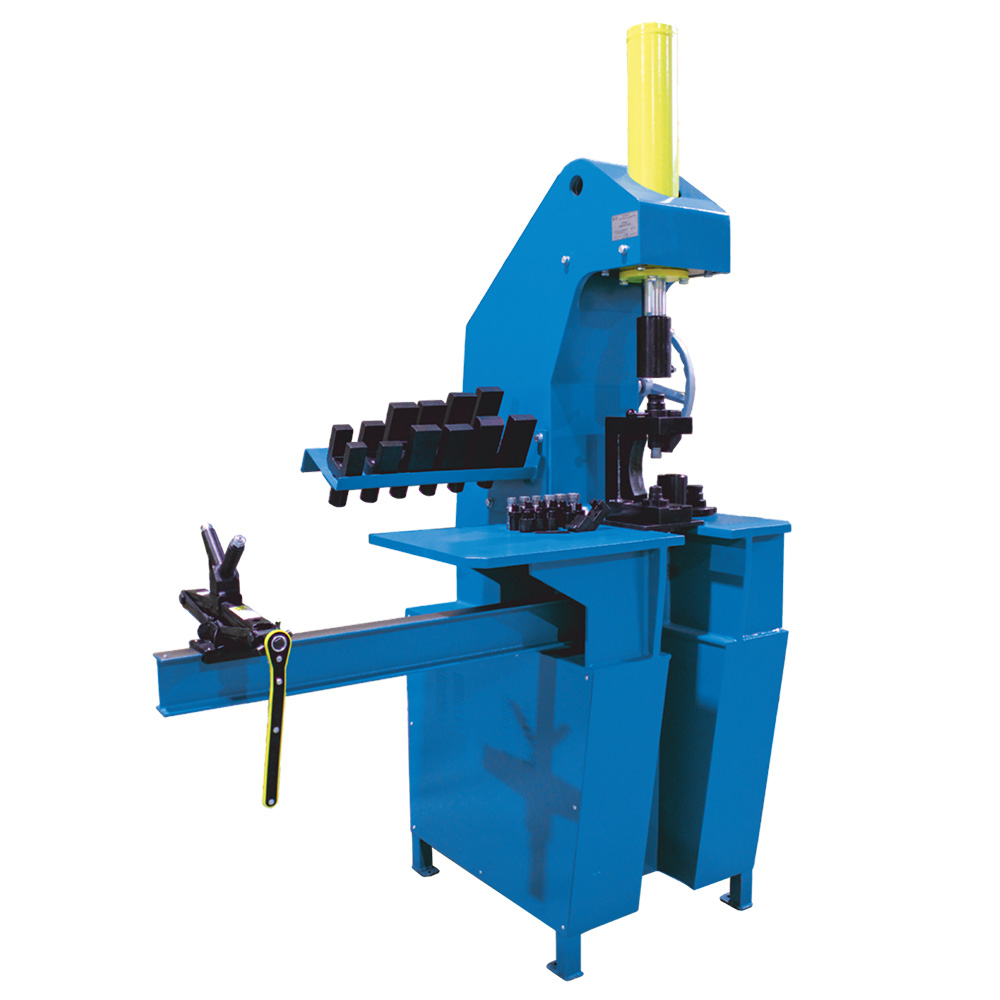

P1515K

Hydraulic driveshaft press for basic repair, assembly & disassembly operations. Max force 15,000 kg

1500

Maximum compressive force, N

400

Maximal stroke, mm

Essential tool for U-joint assembly & disassembly

Hydraulic press P1515K is designed for disassembly and assembly of hinges, pressing forks and spline pairs driveshaft pipe, removal and installation of the outboard bearing and the propeller shaft sliding flange, punching of propeller shaft forks crosses during repair and production.

Due to interchangeable accessories the press can be used for assembling and disassembling various assemblies and parts as well as for technological operations such as bending, stitching of keys, installing bearings, stamping, straightening.

Comprehensive Multi-Function Capability

- Complete driveshaft service operations – Handles u-joint assembly/disassembly, fork pressing, spline pair installation, center bearing removal/installation, and sliding flange operations. The comprehensive capability eliminates need for multiple specialized machines in repair facilities.

- Versatile manufacturing operations – Exchangeable tooling enables bending, keyway broaching, bearing installation, punching, and straightening operations beyond driveshaft applications. The versatility maximizes equipment utilization across diverse workshop requirements.

- Production and repair compatibility – Design accommodates both high-volume production environments and individual repair operations through flexible tooling and control systems.

Advanced Control and Safety Features

- Variable speed hydraulic control – Manual handwheel adjustment provides infinite speed control from full stop to maximum rate with immediate response. The variable control enables optimization for different materials and operations while maintaining precision.

- Proportional force response – Force output directly proportional to handwheel position with automatic reduction to minimum when released. This proportional control prevents over-pressing while ensuring adequate force application for successful operations.

- Large working envelope – 416mm maximum billet height with 900×384mm table dimensions accommodate substantial driveshaft assemblies and components. The generous workspace provides flexibility for diverse repair and manufacturing operations.

Specialized Tooling System

- Comprehensive fork set – Upper forks in sizes 27, 42, 48, 52-53, 57, and 65-72mm cover standard automotive and commercial vehicle applications. The complete range eliminates need for additional tooling while ensuring compatibility across vehicle types.

- Professional punch sets – Eight-piece set (20-31mm) for driveshafts and four-piece set (15-19mm) for steering shafts with centering housing for precise alignment. The specialized tooling ensures accurate pressing while preventing component damage.

- Driveshaft support system – Lift with guide provides stable support for driveshaft assemblies during pressing operations. The support system maintains proper alignment while reducing operator effort during component handling.

High-Capacity Hydraulic System

- Maximum force capability – 15,000kg compression force handles heavy-duty driveshaft operations including truck and industrial applications. The high capacity enables pressing of large u-joints, forks, and spline pairs in demanding commercial vehicle repairs.

- Extended stroke capability – 400mm maximum cylinder stroke accommodates large driveshaft assemblies and deep pressing operations. The extended stroke provides versatility for diverse component sizes and complex assembly procedures.

- Precision force control – Metering pump system with handwheel control provides simultaneous speed and force regulation with proportional response. Manual control enables precise operation with immediate force release for enhanced operator safety and component protection.

- Large hydraulic reservoir – 40-liter oil tank provides adequate fluid capacity for extended operation cycles and consistent performance. The large capacity ensures reliable operation during continuous production or repair operations.

- Professional power requirements – 380V three-phase power supply with 2.2kW consumption provides adequate performance for demanding industrial applications. The professional electrical requirements ensure reliable operation in commercial workshop environments.

|

Parameter |

Value |

|---|---|

|

Drive type |

Hydraulic |

|

Maximum compressive force, N |

1500 |

|

Maximum cylinder stroke, mm |

400 |

|

Working area dimensions (length x width x height), mm |

900 x 384 x 416 |

|

Hydraulic system working pressure, MPa |

160 |

|

Oil tank capacity, l |

40 |

|

Electric motor power, kW |

3 |

|

Power supply parameters |

230V ± 10%, 1 Ph, 50Hz ± 1 |

|

Overall machine dimensions (length x width x height), mm |

1475 x 1875 x 2210 |

|

Machine weight, kg |

600 |

| Driveshaft assembly press P1515K | 1 pc. | |

| Set of thrust forks for disassembling hinges | 1 set | |

| Fork-27 | 1 PC. | |

| Fork-42 | 1 PC. | |

| Fork-48 | 1 PC. | |

| Fork-52-53 | 1 PC. | |

| Fork-57 | 1 PC. | |

| Fork-65-72 | 1 PC. | |

| Emphasis | 1 PC. | |

| Lifter with guide to support the gimbal | 1 set | |

| Manual | 1 pcs. | |

Additional equipment – OPTIONAL

- Centering bracket for punching;

- Cross punching punches

diameters 19mm, 22mm, 24mm, 25mm, 27mm, 30mm, 31mm.

The need for delivery and the volume are negotiated separately, the cost of the basic delivery set is not included, it is paid additionally.

3D Visualization

Free support and training

Request Your Custom Equipment Offer Today

Take advantage of cost savings, unmatched service, and qualification enhancement