Home » Products » Special Balancing Machine » 9D715US

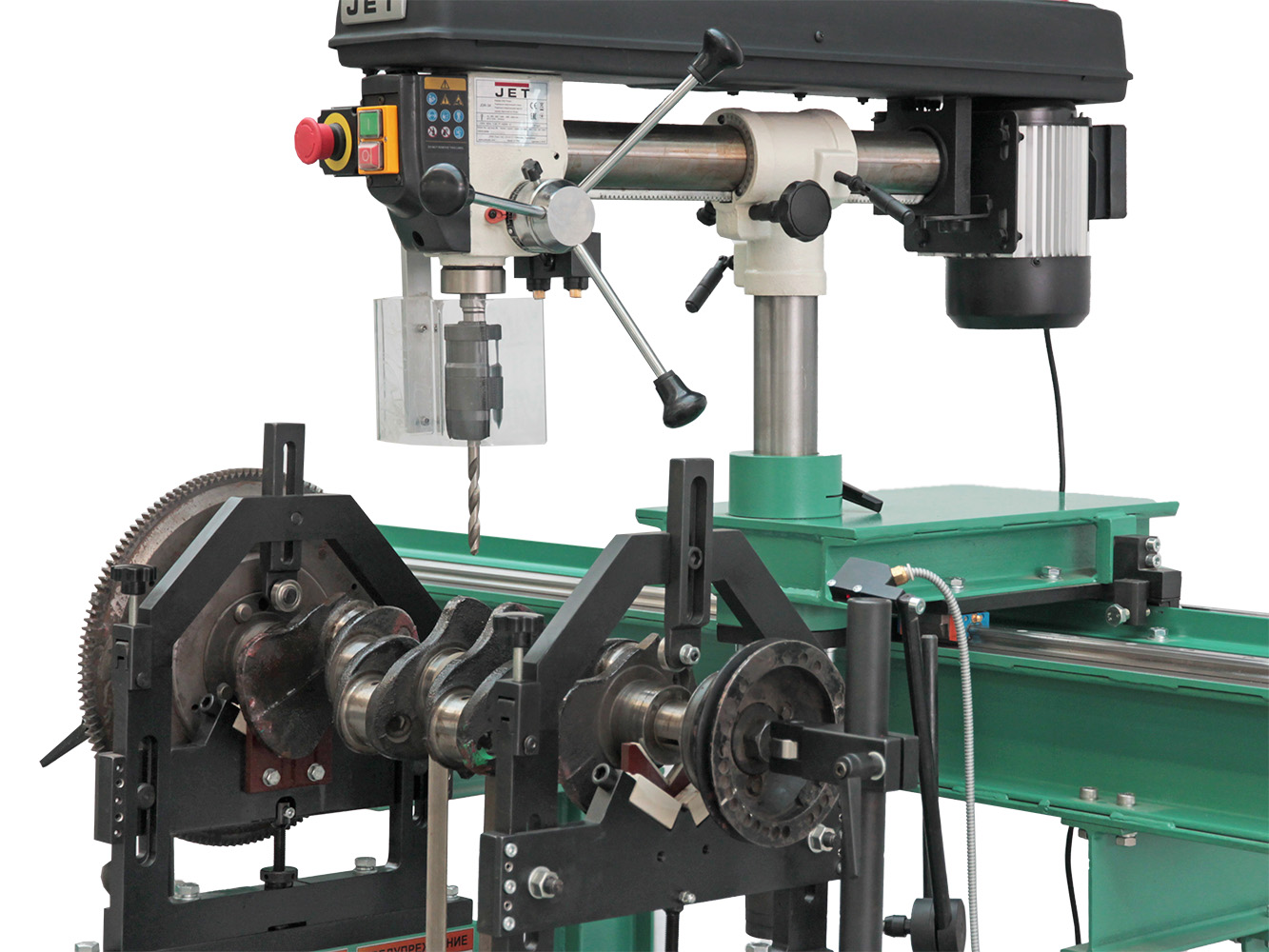

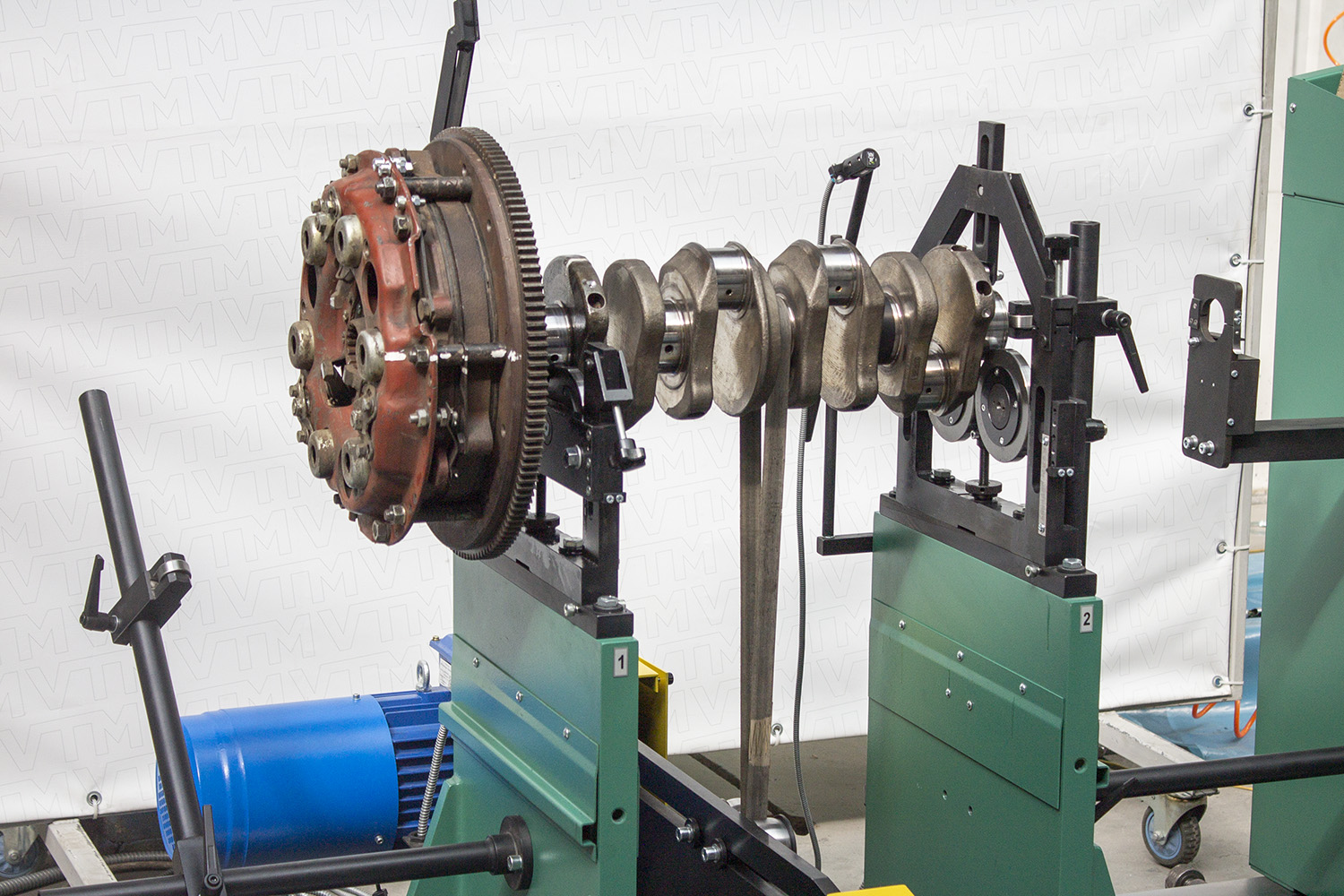

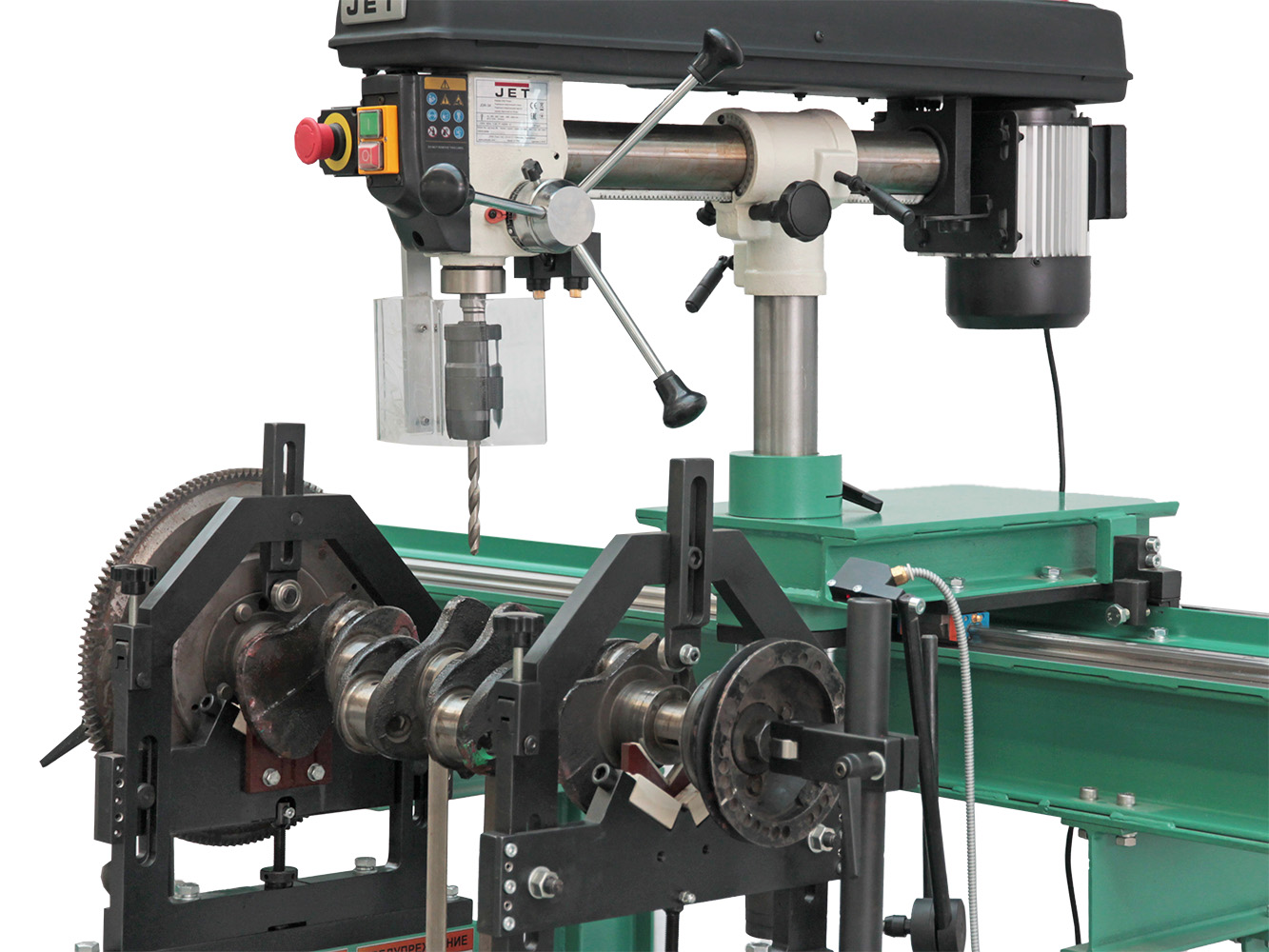

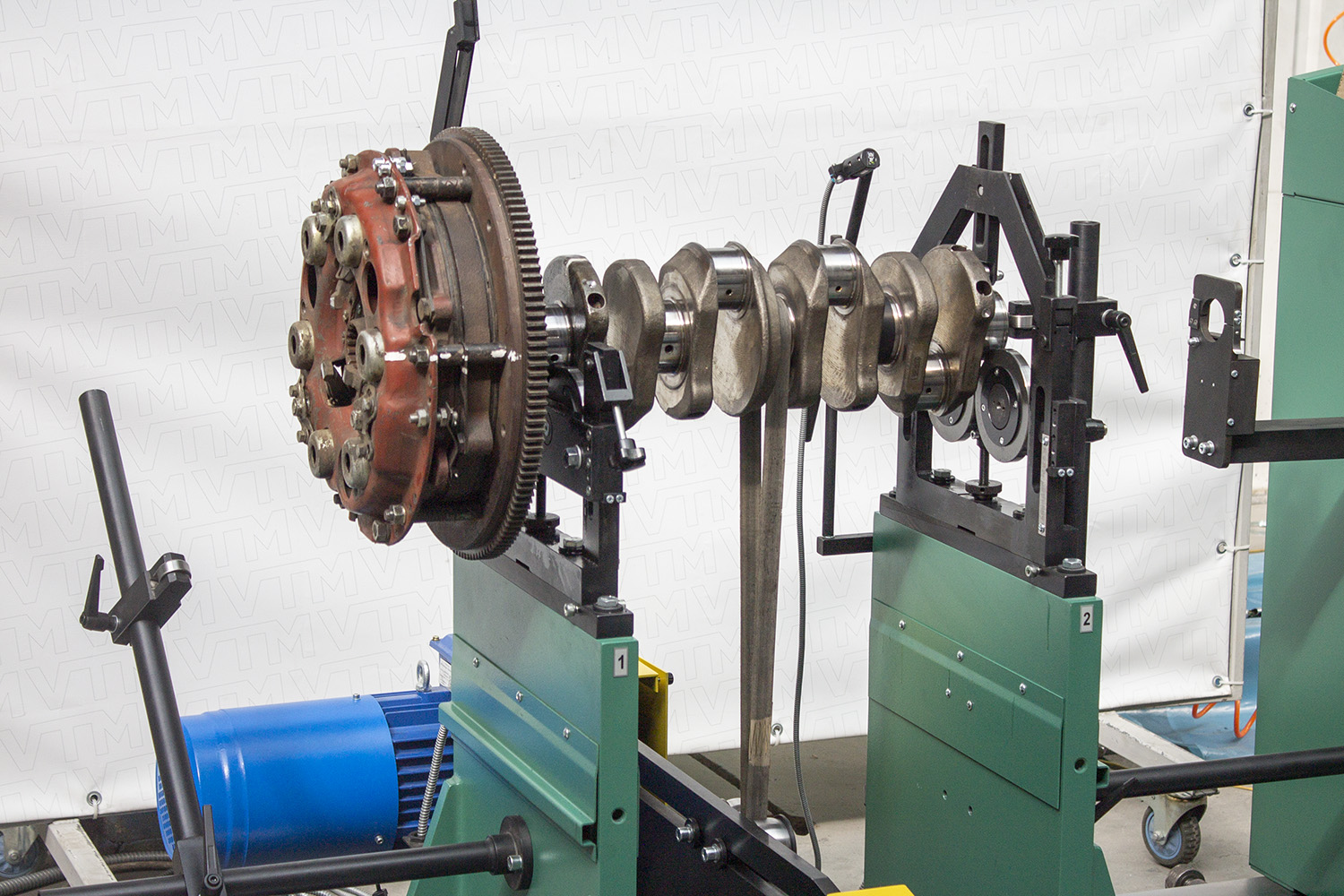

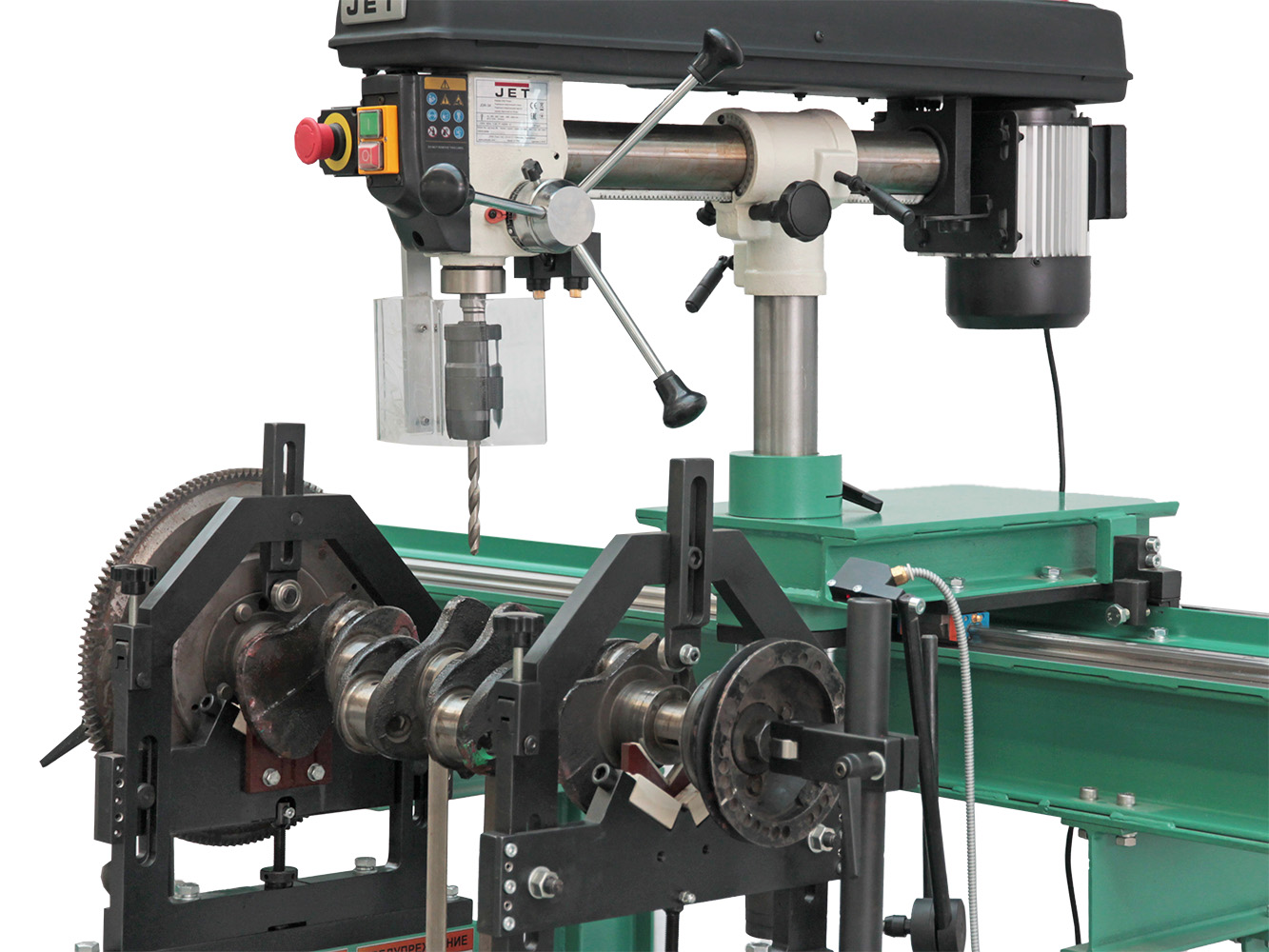

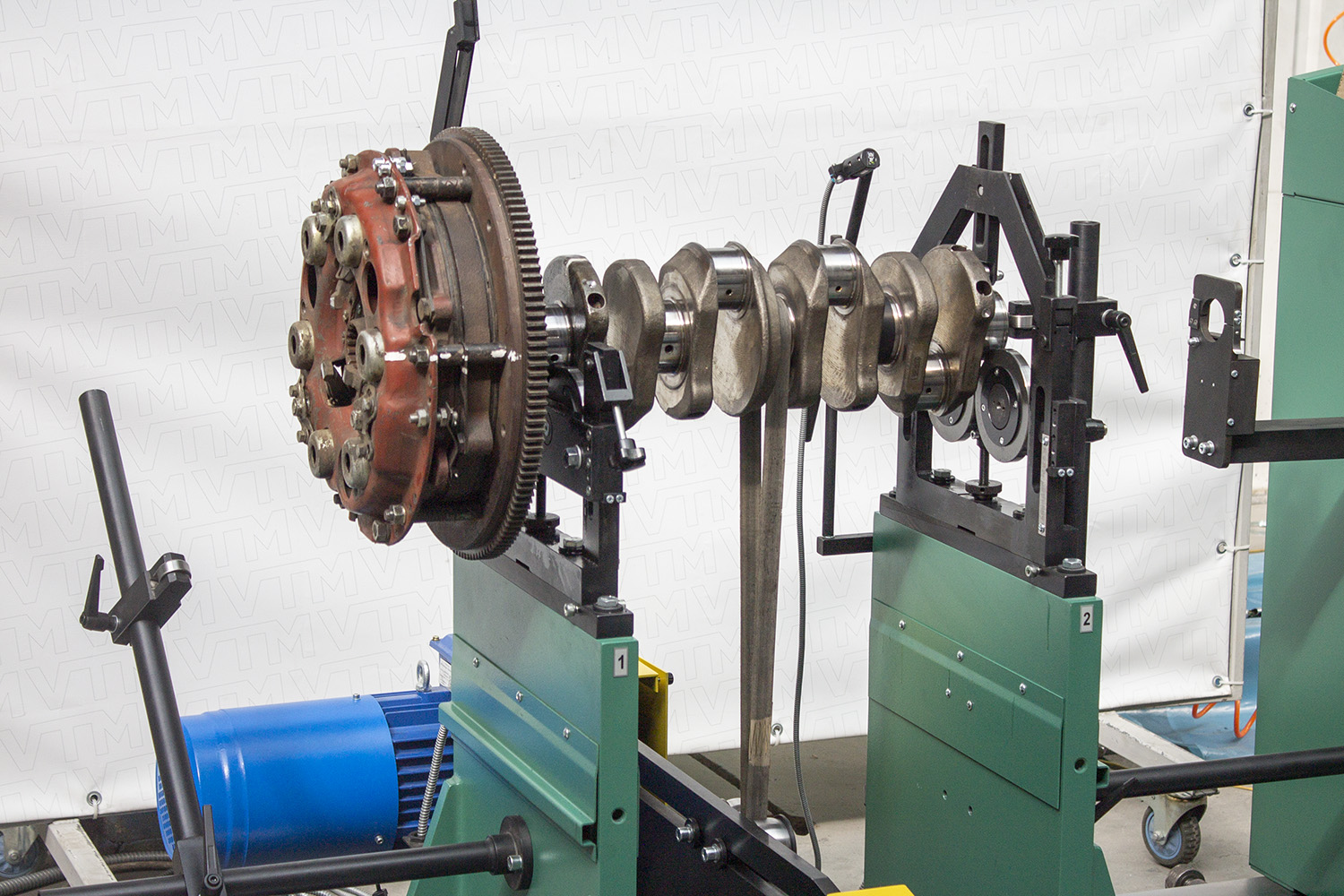

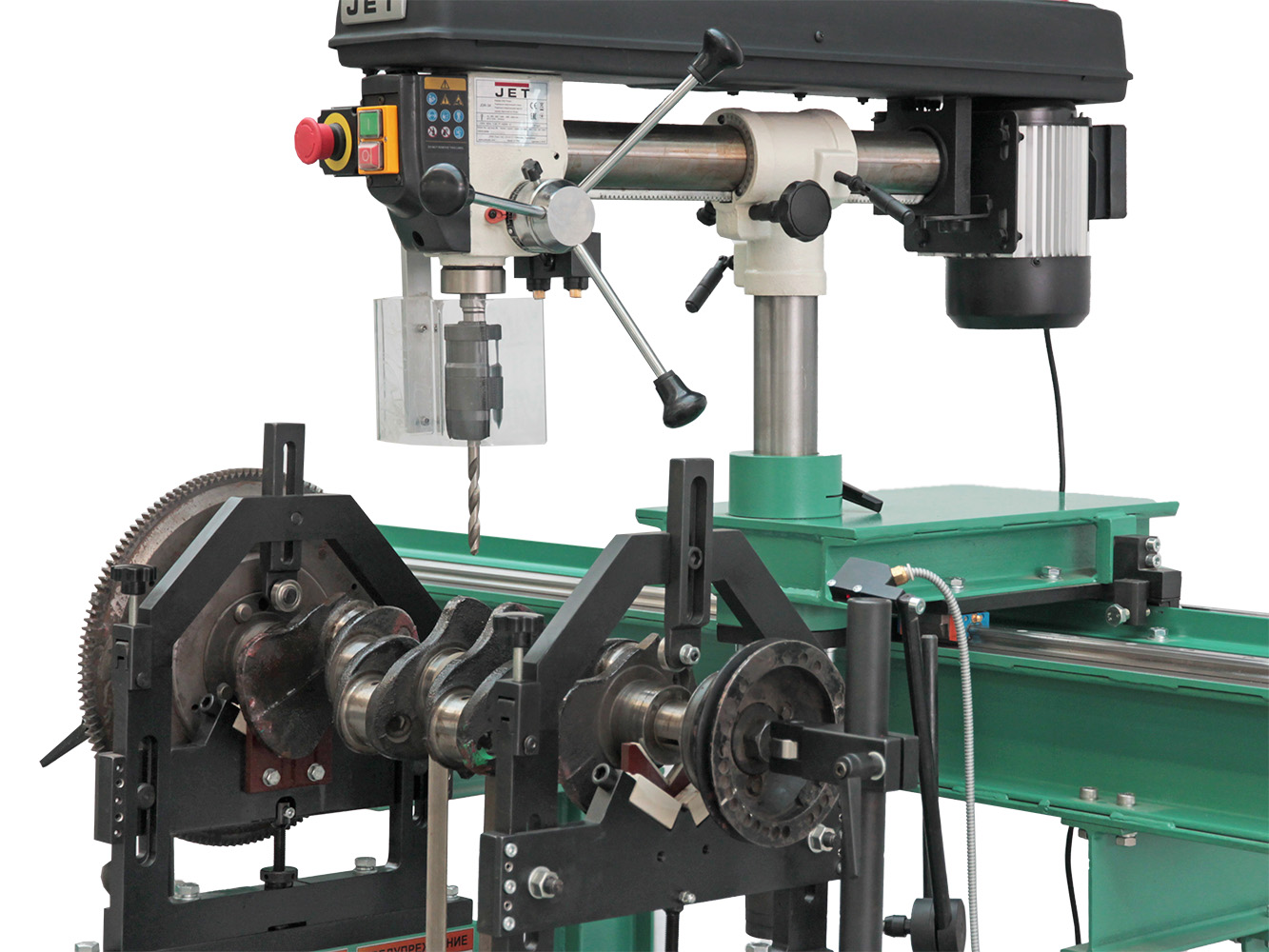

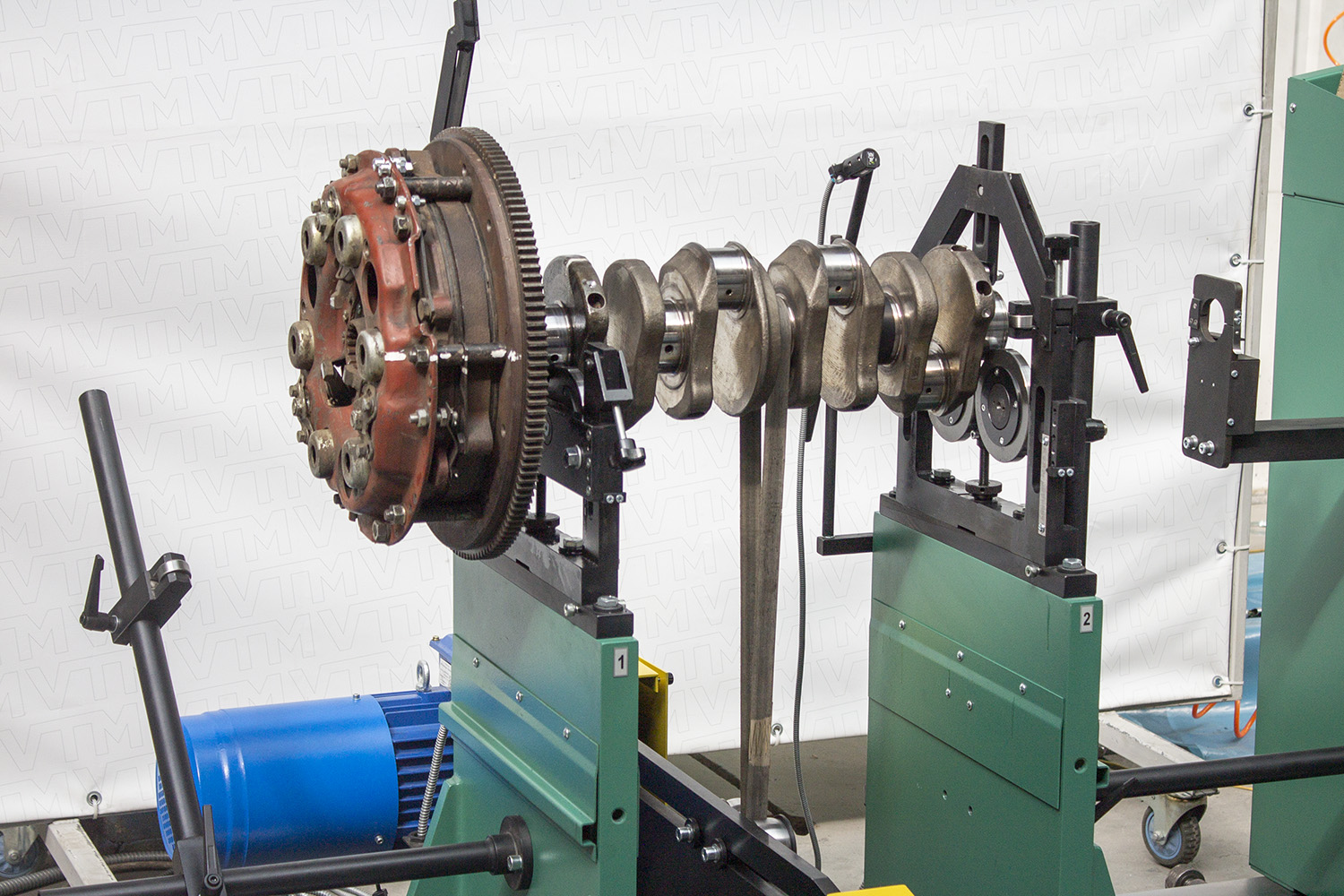

Crankshaft balancing machine up to 300 kg with integrated drilling module

Maximal weight, kg

Maximal diameter, mm

Maximum length, mm

The 9D715US machine has unique capabilities that allow it to effectively handle a wide range of crankshaft balancing tasks in engine overhaul shops.

Thanks to its innovative technology and high performance, it solves the following tasks:

With the 9D715US balancing machine you get a reliable and powerful tool for high accuracy and quality crankshaft balancing.

The universal balancing machine model 9D715US can handle these types of parts :

The unbalance is detected by means of force sensors located in the vibrating supports and a velocity sensor which monitors the rotation of the part. The force transducers convert the support vibrations caused by the unbalanced part into digital signals. The rotational frequency of the part is also converted into electrical pulses. The information from the sensors is processed by the balancer’s computing unit, then output in a convenient format to an information output device such as a computer or a microprocessor screen.

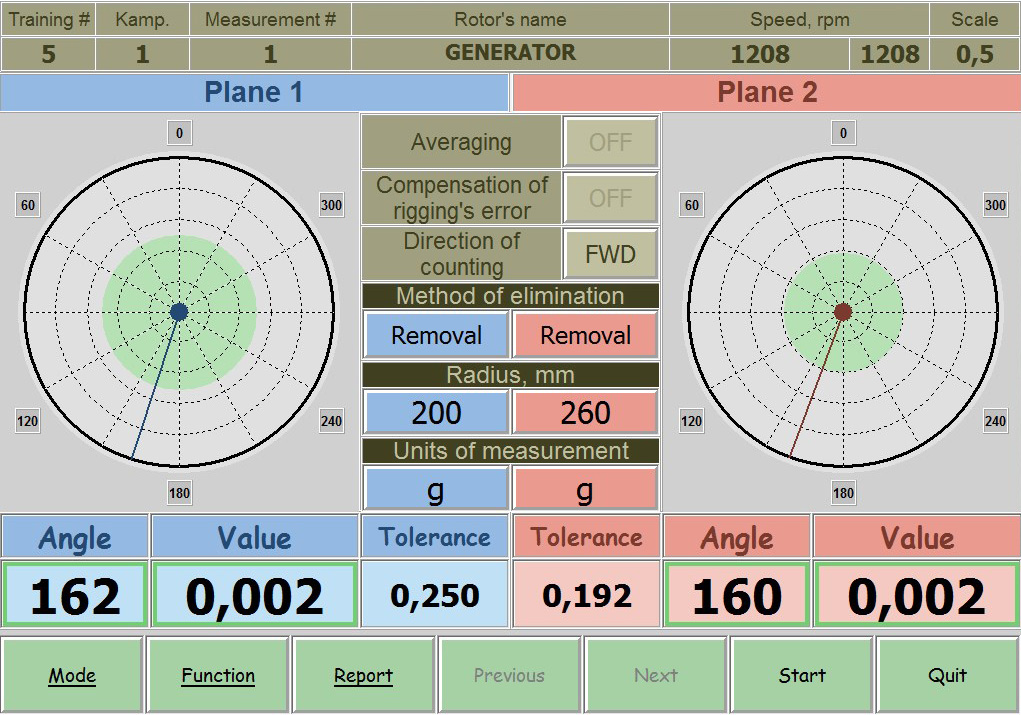

The PAK-1 unbalance measuring unit represents the latest generation of measuring complexes for dynamic balancing, combining high precision, stability, and ease of use. It’s designed to tackle a wide range of rotor balancing tasks, from simple to the most complex, requiring precise measurements.

Based on an industrial fanless computer with a touchscreen and a multi-channel measuring unit, the system ensures reliability and a long service life, even under intensive use. The PAK-1 utilizes a universal measuring path and modern component base, allowing for equally high accuracy when working with all types of rotors.

Its intuitive interface, self-calibration capability, and automation of key operations make the complex a convenient tool for both experienced specialists and beginners.

|

Parameter |

Value |

|---|---|

|

Balancing rotors weight range, kg |

3 – 300 |

|

Maximum rotor diameter (over the bed), mm |

1100 |

|

Distance between rotor bearing journal centers, mm, min/max |

150 – 1350 |

|

Rotor bearin journals diameter, mm |

20 – 140 |

|

Machine type |

Hard-bearing |

|

Support type |

Rollers |

|

Minimal achievable residual specific unbalance, gmm/kg |

0.4 |

|

Rotor rotation speed range, rpm |

300 – 1500 |

|

Drive type |

Belt |

|

Electric motor power, kW |

2.2 |

|

Power supply parameters |

400V ± 10%, 3 Ph, 50Hz ± 1 |

|

Balancing system |

PAK-1 |

|

Overall machine dimensions (length x width x height), mm |

2100 x 1100 x 1500 |

|

Machine weight, kg |

450 |

Leave a request and our manager will contact you to answer questions via your preferred messenger.