Home » Products » Universal Balancing Machine » Vertical Balancing Machine » 97V100

Vertical balancer for medium rotors up to 100kg, robust construction, reliable operation

Maximal weight, kg

Maximal diameter, mm

Maximum height, mm

The balancing machine model 97V100 is a special equipment with a vertical axis of rotation. The machine is designed for balancing single-plane rotors with a weight not exceeding 100 kg. The machine can be used both in repair shops with a large nomenclature of balancing products and at productions with small batch and serial production.

It is possible to balance such parts on the machine:Disk-type component optimization – Design specifically optimized for diverse disk-type rotors including automotive components, industrial discs, and cutting tools. The optimization ensures compatibility with components lacking traditional bearing surfaces.

Automotive component accommodation – Specialized capability for dual mass flywheels, torque converters, clutch baskets, and brake components. The design accommodates challenging automotive geometries while maintaining measurement precision.

Industrial application versatility – Design flexibility enables balancing of pump impellers, fan components, couplings, and separator discs across diverse industrial applications. The versatile configuration maintains accuracy across varied component types.

Custom specification capability – Full production cycle manufacturing enables custom machine configurations differing from standard specifications. This capability accommodates unique application requirements while maintaining design integrity.

Maximum envelope accommodation – Support for rotors up to 550mm diameter and 200mm height within 100kg weight capacity provides substantial component range. The envelope specifications accommodate diverse disk-type industrial and automotive components.

Serial production optimization – Design features optimized for efficient operation in serial, small-scale, and single production environments. The optimization provides operational flexibility across diverse manufacturing scenarios while maintaining consistent performance.

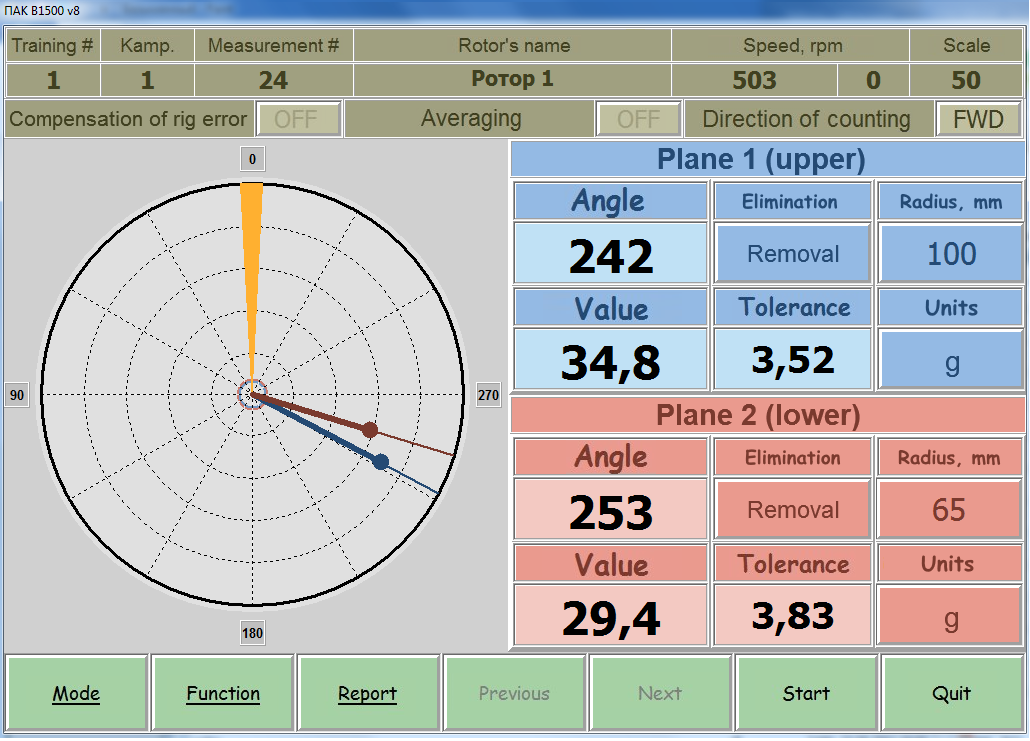

The PAK-1V unbalance measuring unit is a 2-plane measuring balancing system for balancing disc-type rotors on vertical balancing machines. It can perform static (single-plane) balancing in dynamic mode on a two-plane balancing machine.

Based on an industrial fanless computer with a touchscreen and a multi-channel measuring unit, the system ensures reliability and a long service life, even under intensive use. The PAK-1V utilizes a universal measuring path and modern component base, allowing for equally high accuracy when working with all types of rotors.

Its intuitive interface, self-calibration capability, and automation of key operations make the complex a convenient tool for both experienced specialists and novice beginners.

|

Parameter |

Value |

|---|---|

|

Balancing rotors weight range, kg |

1 – 100 |

|

Maximum rotor diameter (over the bed), mm |

550 |

|

Maximum rotor height, mm |

200 |

|

Machine type |

Hard-bearing |

|

Minimal achievable residual specific unbalance, gmm/kg |

4 |

|

Rotor rotation speed range, rpm |

300 – 1000 |

|

Number of measured rotor correction planes |

1 & 2 |

|

Electric motor power, kW |

4 |

|

Power supply parameters |

400V ± 10%, 3 Ph, 50Hz ± 1 |

|

Balancing system |

PAK-1V |

|

Overall machine dimensions (length x width x height), mm |

1800 x 1100 x 1500 |

|

Machine weight, kg |

700 |

Leave a request and our manager will contact you to answer questions via your preferred messenger.