Home » Products » Garage equipment » Turbocharger Repair Equipment » VSR Balancing Machine » SBR-20

SBR-20

High-speed stand for large turbo. Up to 150,000 rpm. Simulates real conditions

35

Maximal weight, kg

179

Maximum compressor wheel diameter, mm

Balances turbos for truck, railway, and marine machinery

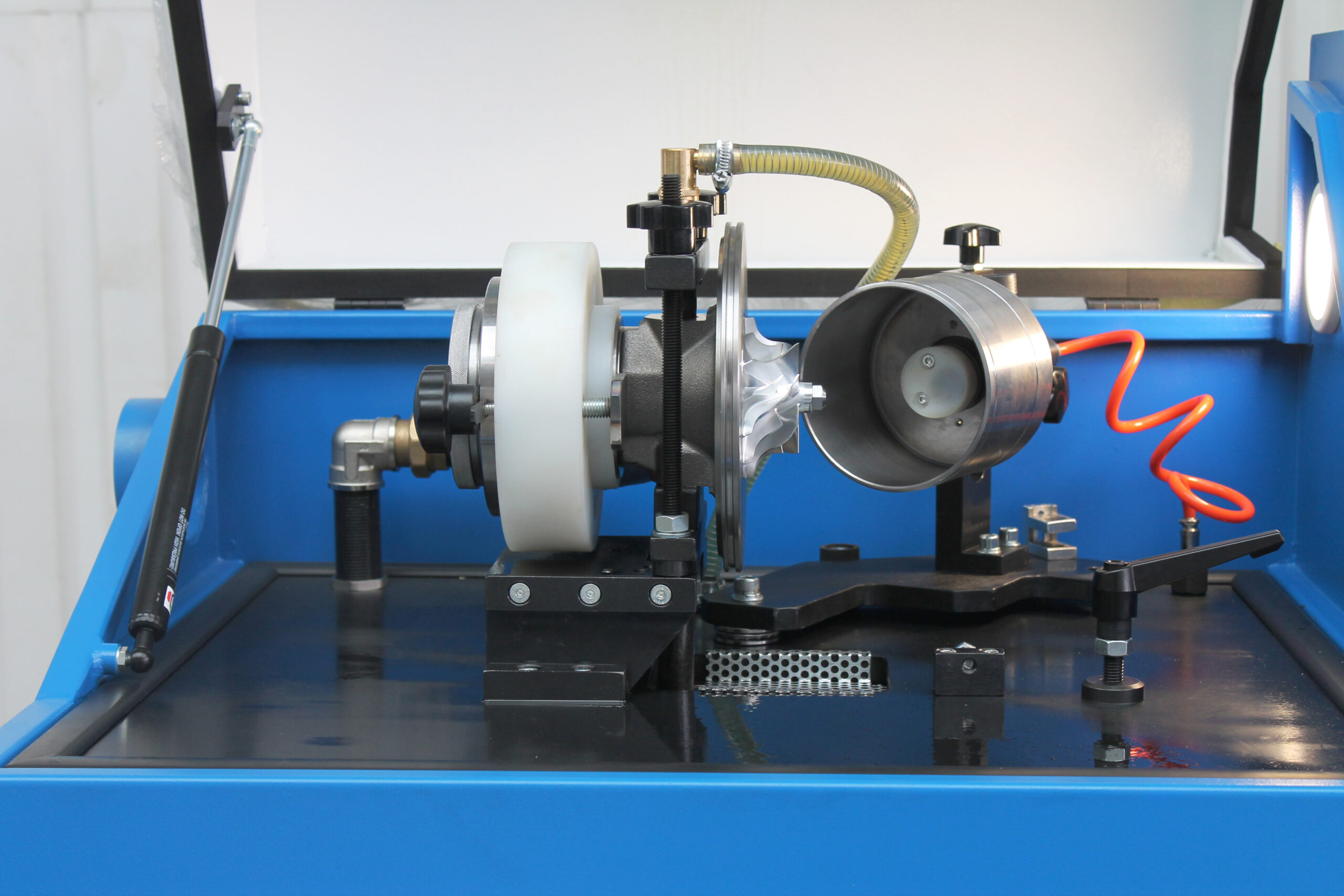

The machine is designed for the high-speed balancing of turbochargers at speeds reaching maximum operational values to eliminate the dynamic unbalance of the turbine rotor. Used for balancing large turbochargers of special equipment, railroad and marine turbines, industrial turbochargers for diesel generators. The SBR-20 simulates the same conditions during testing and balancing as during the operation of a turbocharger on a car; this allows you to guarantee the quality of the repair.

The main task of the SBR-20 is to determine the intensity and direction of the deflection as well as in what exact period of time and at what frequencies it appeared. This information is being analyzed by measuring system and it is possible to balance the shaft of the turbine.

The second task is to prevent damaging the parts of the turbocharger during the balancing process. The hydraulic system is installed in machine in accordance with this task. It helps to create an “oil wedge” in the gaps between the parts of the turbo compressor which prevents the parts from contacting each other and their reliable protection is ensured.

The SBR-20 emits the same conditions during testing and balancing as when the turbine is operating within a car and this allows us to guarantee the quality of repair of this unit.

A well-balanced turbocharger has a long service life which reduces the return rate of turbochargers and helps to build up your reputation.

The universal adapter set and accessories cover mostly all turbocharger core types including reverse rotation ones.

- Any turbocharger installation

- All type turbocharger adapters

- Own advanced measuring system

- Impeller safety cover

- Fast oil heater and temperature regulation

- Displaying real time imbalance measuring

- An industrial fanless touch screen pc control system

- Ethernet connection for diagnosis

- Language selection

- Customised print out of balance data

- Data storage to internal flash memory and usb memory stick

- Operation & service personalized manuals

- Intuitive simple operationing

- High product reliability

- Reverse rotation support

- Low-cost spare parts

- OEM and aftermarket repairs

Heavy-Duty Industrial Turbocharger Engineering

- Enhanced capacity turbocharger specialization – Engineered for high-speed balancing of heavy-duty truck, marine, and agricultural turbocharger cartridges up to 150,000 rpm with maximum compressor wheel diameter of 175mm. This expanded capacity version addresses the demanding requirements of larger commercial and industrial turbocharger applications where size and performance exceed standard automotive specifications.

- Operational speed simulation for heavy-duty applications – Replicates exact operating conditions encountered in truck, marine, and agricultural applications at operational speeds up to 150,000 rpm, ensuring guaranteed repair quality for heavy-duty turbochargers. This capability enables elimination of dynamic deflection effects specific to larger turbochargers operating under demanding industrial conditions.

- Flexible rotor behavior analysis for larger rotors – Addresses the critical transition above 50,000 rpm where heavy-duty turbocharger shafts exhibit enhanced “flex type” rotor characteristics due to increased mass and length. The machine analyzes deflection intensity, direction, and frequency patterns specific to larger turbocharger configurations for precise balancing solutions.

- 0.01G ultra-precision measurement – Achieves exceptional balancing accuracy of 0.01G specifically calibrated for high-speed turbocharger applications where minute unbalances create significant operational issues. This precision level ensures optimal turbocharger performance and extended service life under demanding automotive operating conditions.

- Soft suspension vibrating table – High-sensitivity equipment design utilizing soft suspension system for enhanced measurement capability at extreme operating speeds. The specialized suspension isolates external vibrations while maintaining structural integrity during high-speed operation.

Universal Large Turbo Compatibility

- Comprehensive heavy-duty cartridge mounting – Universal mounting system accommodates virtually all truck, marine, and agricultural turbocharger models using supplied equipment, establishing maximum versatility for diverse industrial applications. The enhanced compatibility eliminates equipment limitations when servicing mixed fleets of heavy-duty equipment.

- Adaptive cartridge adapters – Multiple adapter configurations enable installation of various turbocharger designs including systems with reduced oil supply requirements. The adapter system provides flexibility for different turbocharger manufacturers and specifications while maintaining measurement accuracy and protection levels.

- Turbine housing simulation – Plastic adapters simulate actual turbine housing conditions while protecting turbine wheels from rubbing damage due to operator error. The low-hardness material design provides realistic operating simulation while offering protection against accidental contact during high-speed operation.

- Self-manufactured adapter capability – Adapter equipment designed for easy manufacture, enabling shops to create or modify adapters for new turbocharger models independently. This self-sufficiency capability ensures compatibility with emerging turbocharger designs without factory support requirements.

Real-Time Measurement and Safety

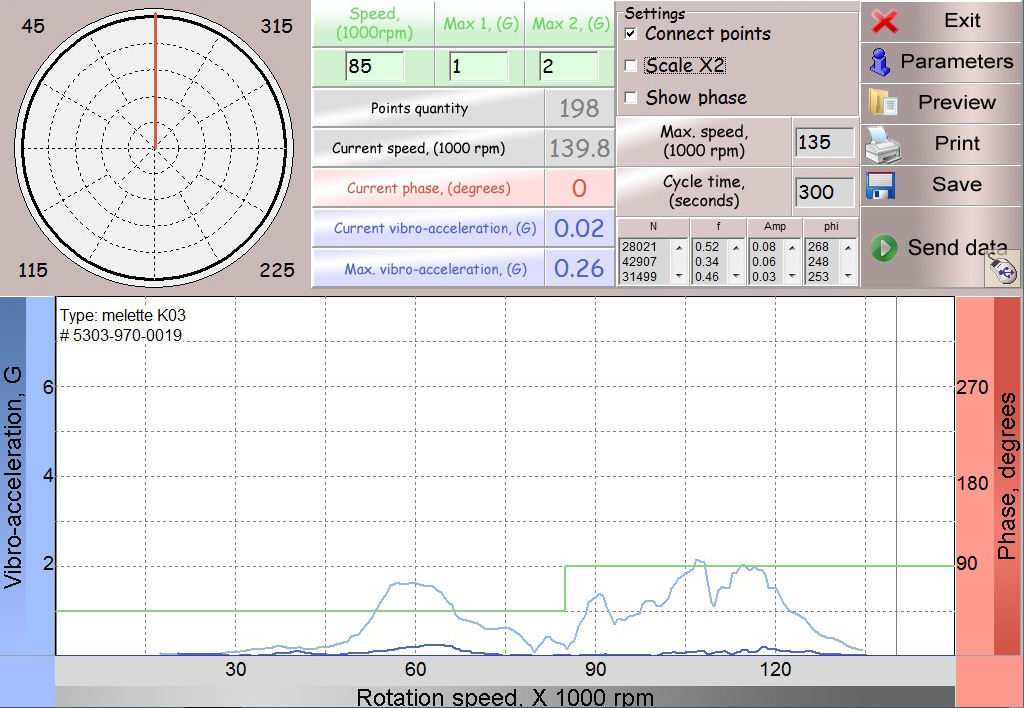

- PAK-SBR specialized control system – Custom-designed balancing system provides real-time unbalance measurement during rotation, preventing possible turbine destruction during testing. The specialized system offers high noise immunity ensuring reliable signal transmission from vibration sensors under demanding operating conditions.

- 10G vibration measurement capability – Measures center housing vibration up to 10G, providing twice the measurement range of European turbocharger standards. This extended range accommodates severely damaged or heavily unbalanced turbochargers commonly encountered in repair operations.

- Graphical acceleration analysis – Displays vibration acceleration and phase versus rotational speed during turbine acceleration with simultaneous dual-measurement capability for comprehensive turbocharger analysis. The intuitive graphical interface simplifies data interpretation and accelerates diagnostic procedures.

- Phase display and location identification – Pie chart phase display enables easy unbalance location identification for precise correction procedures. The visual phase presentation simplifies operator decision-making and reduces correction time for enhanced productivity.

Advanced Hydraulic Protection System

- Oil wedge protection technology – Integrated hydraulic system creates protective “oil wedge” in gaps between turbocharger components, preventing contact during high-speed balancing operations. This protection system enables safe operation at extreme speeds while protecting valuable turbocharger components from damage during the balancing process.

- Triple-stage oil purification – Hydraulic oil undergoes three-stage purification process ensuring turbocharger component safety and enabling unbalance correction without cartridge removal from the machine. The comprehensive purification system maintains oil cleanliness critical for turbocharger bearing protection and eliminates readjustment time.

- 16-liter oil station capacity – Large-capacity oil tank reduces oil change frequency while minimizing heating time for operational efficiency. The substantial oil volume ensures consistent hydraulic performance throughout extended balancing sessions while maintaining optimal operating temperatures through thermal relay control.

- Temperature-controlled oil system – Oil temperature regulation through thermal relay and thermocouple system maintains optimal hydraulic performance and component protection. The controlled temperature system ensures consistent operation across varying ambient conditions and extended operating periods.

PAK-SBR specialized unbalance measuring unit, designed specifically for use with the VSR high-speed balancing machine SBR, is an advanced hardware and software complex that ensures highly accurate determination of turbocharger imbalance at rotational speeds up to 300,000 rpm.

The system is built on an industrial fanless computer with a touchscreen and a modern measuring unit, providing high reliability, noise immunity, and user-friendly operation. It measures the vibration of the turbocharger bearing housing up to 10G — twice the capability of most European systems — and displays results in real time, preventing rotor damage during testing. The high data processing speed (up to 2 seconds) reduces the required air receiver volume and increases the overall productivity of the balancing process.

Features of the PAK-SBR System:

- Real-time measurement of vibration during rotor operation.

- Display of vibration, speed, and tolerance in both digital and graphical formats.

- Measurement time as short as 2 seconds, improving overall efficiency.

- Sensitivity up to 0.01G for precise rotor dynamics analysis.

- Graphical display of vibration acceleration and phase versus rotational speed.

- Circular phase diagram for quick identification of imbalance location.

- Simultaneous display of data from two measurements on a single graph.

- Display of tolerance zones for precise quality control.

- Saving and viewing acceleration graphs for detailed post-analysis.

- High noise immunity and stable signal transmission from sensors.

- Industrial fanless computer with a touchscreen interface.

- Windows-based operation for intuitive and user-friendly control.

- Manual editing and expansion of the turbocharger database.

- Pre-installed database of common turbocharger specifications.

- Storage of balancing history in the system memory.

- Printing of detailed reports with results, date, time, and turbocharger parameters.

|

Parameter |

Value |

|---|---|

|

Maximum weight turbocharger cartridge, kg |

35 |

|

Maximum turbine wheel diameter, mm |

110 |

|

Maximum compressor wheel diameter, mm |

179 |

|

Maximum achievable rotor rotation frequency, rpm |

150000 |

|

Pneumatic system operating pressure, MPa |

0.8 |

|

Minimum recommendable receiver volume, m3 |

2 |

|

Power input, kW |

1.5 |

|

Power supply parameters |

230V ± 10%, 1 Ph, 50Hz ± 1 |

|

Overall machine dimensions (length x width x height), mm |

1270 x 700 x 1390 |

|

Machine weight, kg |

285 |

|

Requirements for foundation |

The machine is mounted on a standard hard floor in workshop |

- Oil tank with heated oil for 16L – 1pc.

- Adapter kit to install three types of turbines, including turbine with a lower oil supply – 1 pc.

- Operations manual of the machine with acceptance test report and schematic circuit diagram -1 pc.

- Operating Manual balancing system – 1 pc.

There are no options for this machine

Free support and training

Request Your Custom Equipment Offer Today

Take advantage of cost savings, unmatched service, and qualification enhancement