Home » Products » Garage equipment » Turbocharger Repair Equipment » Turbo Flow Bench » GEOMET-2000

Special offer

* Only in EU. Ready for shipment from Poland.

16 990€

14 000€

7000+

Turbo in database

Static

Test bench

Fast turbocharger geometry adjustment for optimal performance

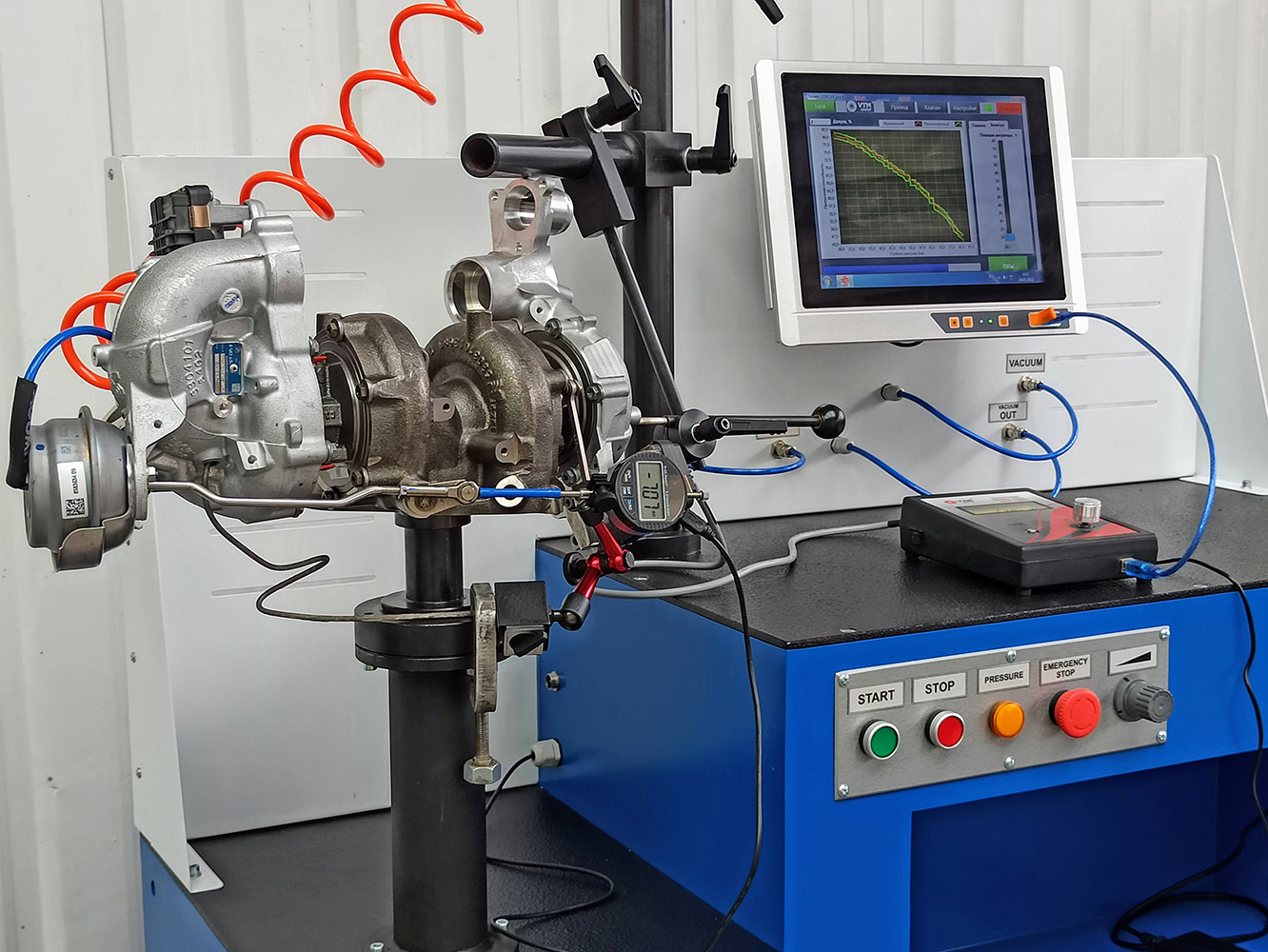

Geomet 2000 is a specialized bench for tuning and testing controlled turbochargers (VNTs). The equipment is adapted to the needs of turbocharger repair workshops. As a rule, this bench is used for adjusting and testing turbochargers of trucks and cars, but its design also makes it possible to work with turbochargers of special vehicles and small boats.

The bench consists of a housing with a powerful air compressor inside which the vacuum (or air pressure) is created during adjustment and testing of turbochargers. The test bench is controlled by an industrial computer with a touch screen and a control panel located on the body of the test bench.With the help of the simulator you can solve such tasks:

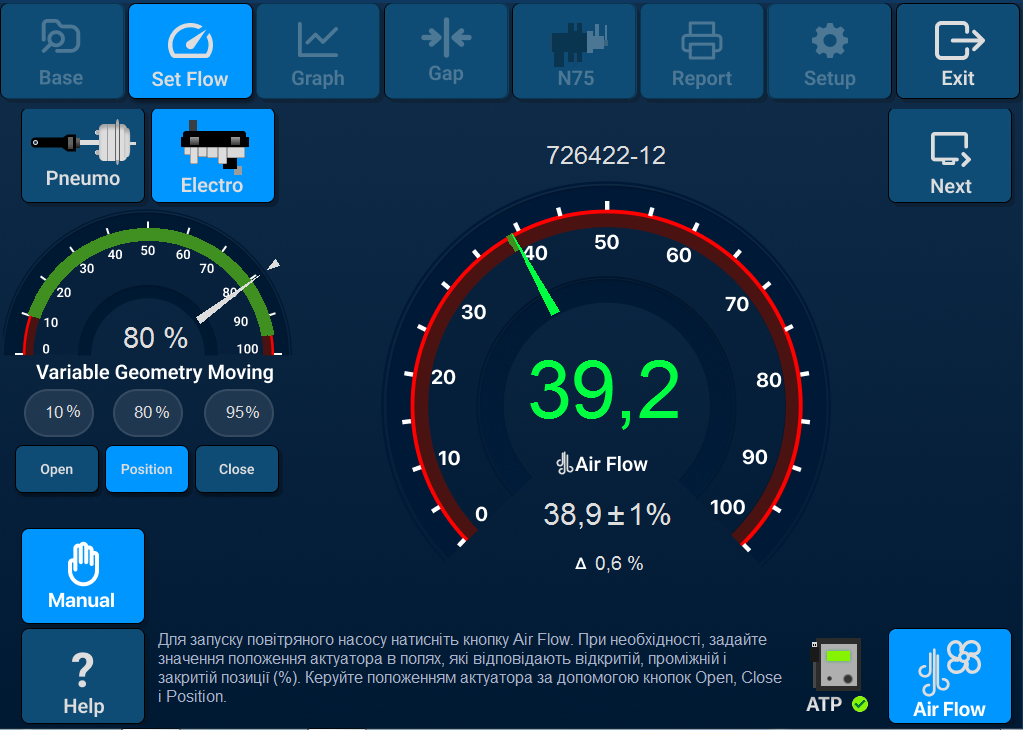

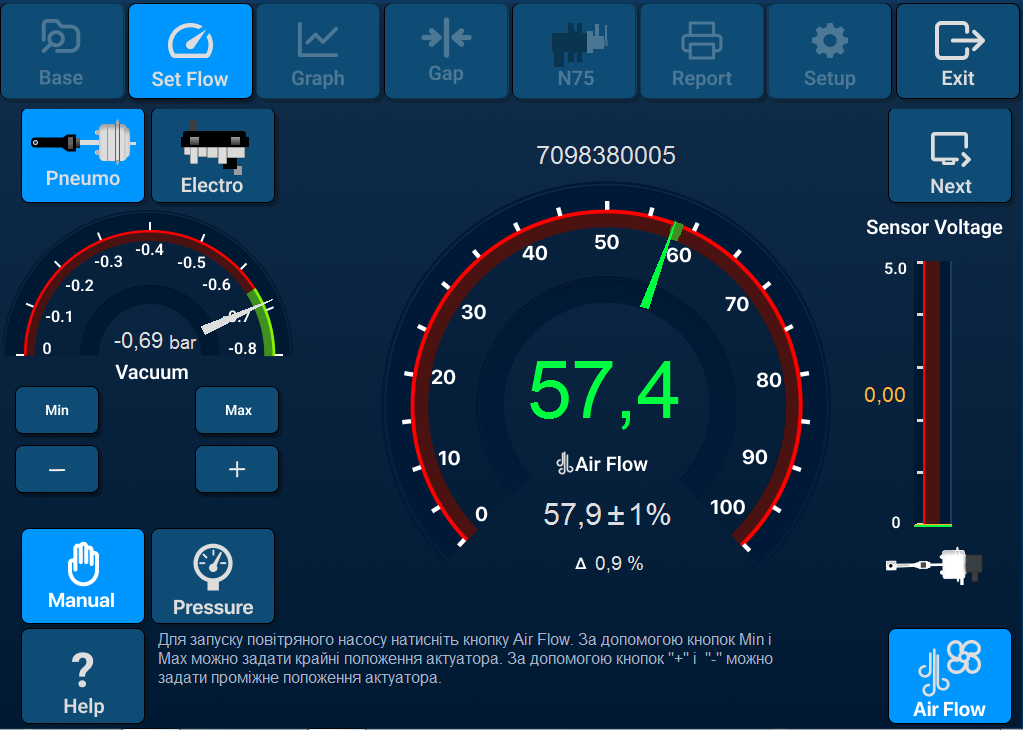

- Diagnostics of controlled turbochargers (VNT) with vacuum, pneumatic or electronic (option) control.

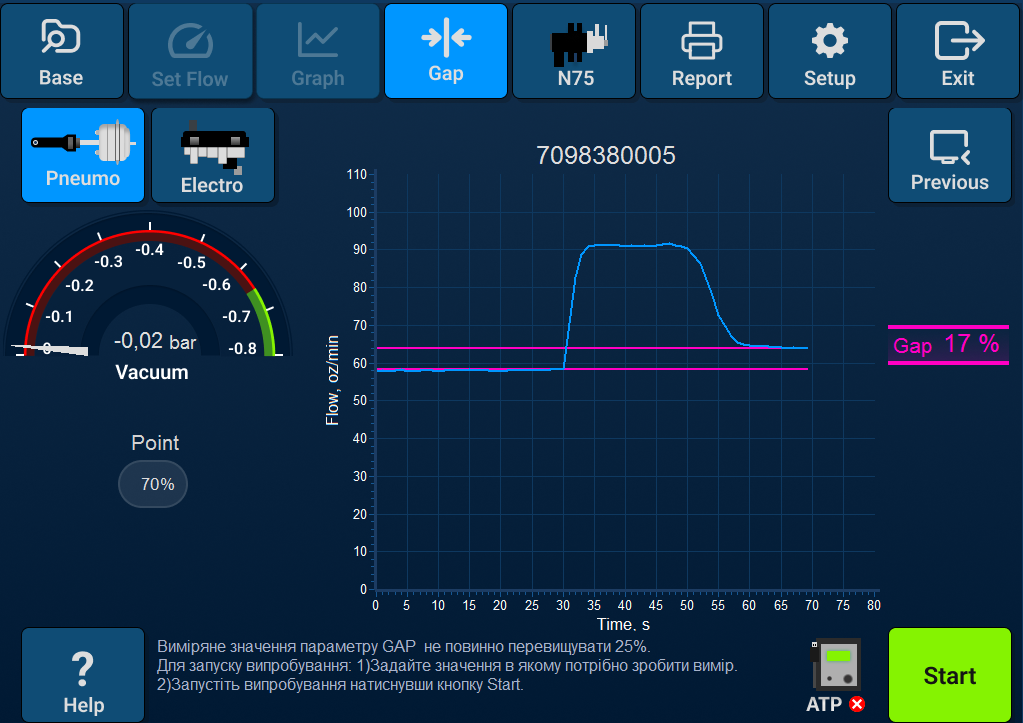

- Adjustment of the stop position of the airflow control mechanism will eliminate the “overblow” effect detrimental to the engine.

- Adjusting the length of the actuator rod to adjust the moment of the airflow control mechanism actuation.

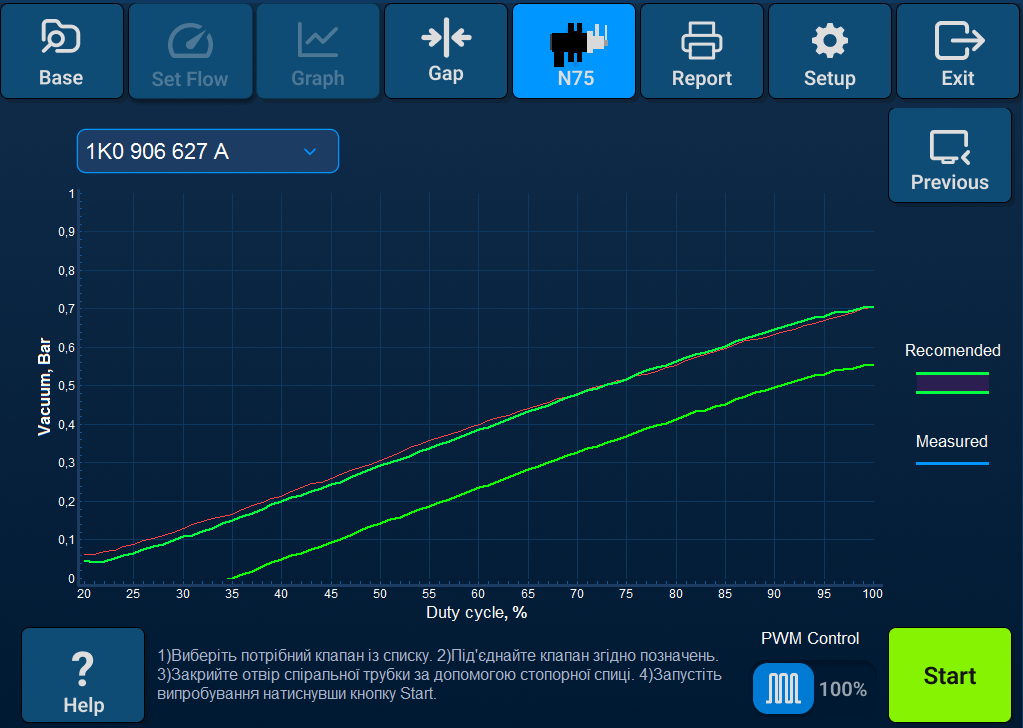

- Check of the control valve N75 (a unique feature of the test bench) to analyze the faults of the turbocharging control system of the car.

- Evaluation of the actuator spring wear degree for in-depth diagnostics of vacuum and pneumatic actuators.

- Transferring the control program (option) when replacing the electronic actuator cover.

- The simulator is adapted for joint work with the ATP-1000 tester-programmer.

The bench adjusts and tests the turbocharger by comparing the inlet and outlet air pressure of the turbocharger when its drive is activated. Shaft rotation locking eliminates the need for an oil station, which reduces the bench’s maintenance and repair costs.

- Installation time of the turbocharger from 5 to 15 seconds thanks to the mounting method and the magnetic adapter.

- Any turbocharger can be installed, even those made of non-magnetic materials.

- The ergonomic design of the stand allows free access to any part or unit of the stand, and the wide table allows to work unobstructed.

- An air filter prevents even the smallest particles from getting into the turbocharger during testing, adjustment or diagnostics.

- High repairability is due to easily accessible components and bench design.

Software features:

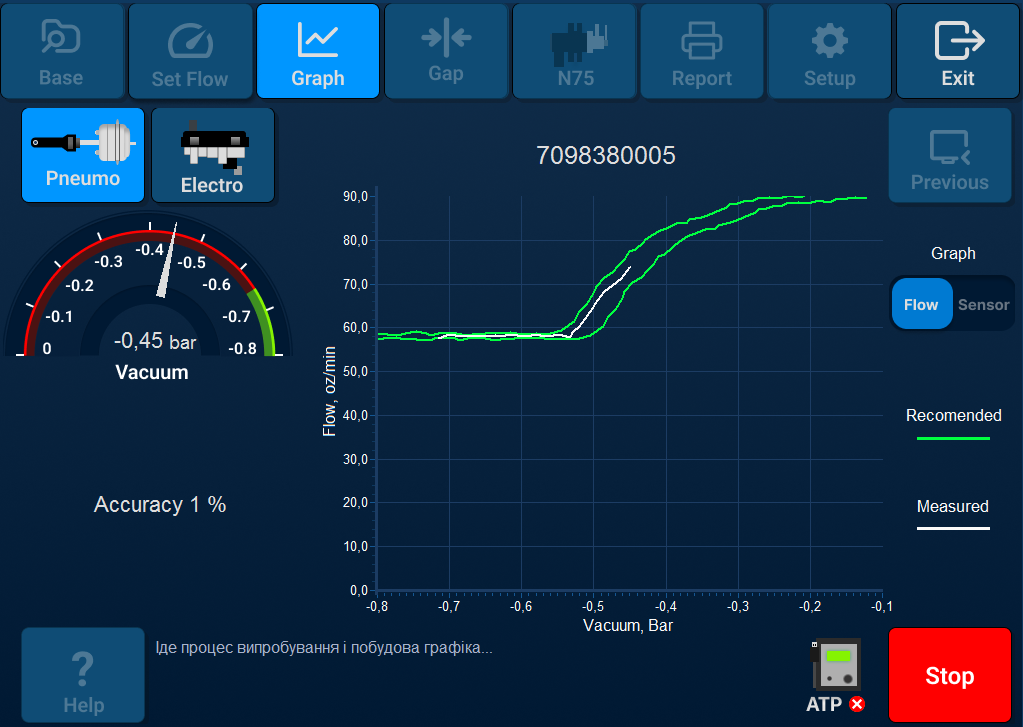

- The “real-time” information display and the availability of tolerance fields make it easy to set up and work on the bench without special training.

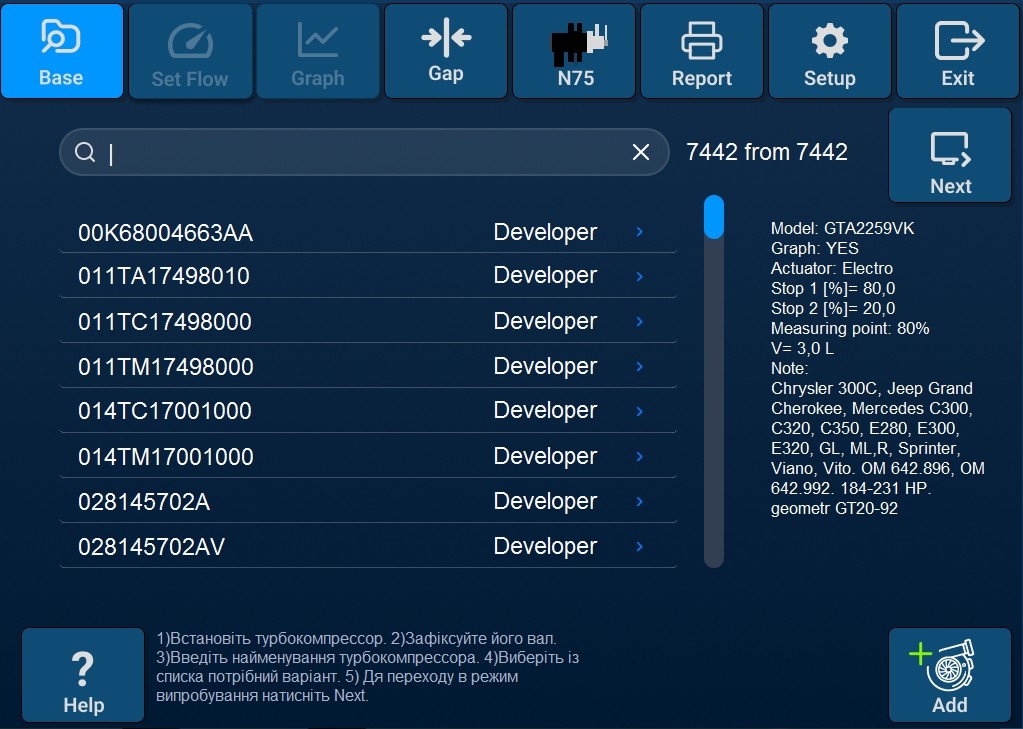

- The large “database of turbine characteristics” (more than 7000) can be replenished independently by taking the characteristics of a new turbine. This makes the stand in demand even after 10 years.

- Calibration of the test bench is done by the operator in 10 seconds. It minimizes errors by automatically taking into account the ambient conditions of the working room.

- The construction of graphs allows a qualitative assessment of the condition of each turbocharger element before and after the repair.

Mechanical Design

- Vertical turbocharger mounting position ensures stable fixation and comfortable access to all components during adjustment and diagnostics.

- Wide working area and ergonomic layout provide unobstructed handling of large and non-standard turbochargers.

- Magnetic adapter and universal clamps enable fast installation of most turbocharger types, including both magnetic and non-magnetic housings.

- Adapter design with expandable configuration allows workshops to easily adapt the bench to regional market requirements.

Air and Drive Systems

- Integrated high-capacity air compressor generates the required vacuum or pressure for precise simulation of turbocharger operation.

- Air filtration system protects the turbocharger under test from fine particles, ensuring reliable diagnostics and preventing contamination.

- No oil circuit in the design simplifies maintenance, reduces operating costs, and eliminates oil-related service issues.

Control and Support Systems

- Industrial-grade control unit with touchscreen interface combines intuitive operation with advanced testing functionality.

- Locking system for turbocharger shaft rotation removes the need for an oil station and reduces system complexity.

- Adjustable stop lock and increased pipe height make it possible to work with oversized or custom turbocharger designs.

- Easily accessible internal components simplify servicing and reduce downtime.

measuring system Geomet-2000

|

Parameter |

Value |

|---|---|

|

Maximum air flow rate of the vortex compressor, m3/min |

180 |

|

Maximum vacuum created by the vacuum pump, mbar |

-700 |

|

Power input, kW |

1.5 |

|

Power supply parameters |

230V ± 10%, 1 Ph, 50Hz ± 1 |

|

Overall machine dimensions (length x width x height), mm |

1200 x 520 x 1730 |

|

Machine weight, kg |

220 |

|

Requirements for foundation |

The machine is mounted on a standard hard floor in workshop |

- Set of adapters for installation of turbines – 1 set

- Digital indicator for measuring the rod stroke – 1 set

- Operation manual – 1 pc

Watch the video review of our machine

This video provides a complete overview of the machine’s design, demonstrates its main operating stages, and shows the process of setup and maintenance. You will see how the equipment operates in real conditions and assess its ease of use.

3D Visualization

Free support and training

Request Your Custom Equipment Offer Today

Take advantage of cost savings, unmatched service, and qualification enhancement