Home » Products » Universal Balancing Machine » Vertical Balancing Machine » 97V300

Industrial vertical balancer for large rotors up to 300kg, maximum precision & stability

Maximal weight, kg

Maximal diameter, mm

Maximum height, mm

The balancing machine model 97V300 has a vertical axis of rotation and is a universal pre-resonance type equipment. The machine is designed for balancing disc-shaped parts with a mass of up to 300 kg. Its high degree of versatility has made this model popular in repair shops with a wide range of products being balanced and its high output is very popular with serial manufacturers.

Although the machine is suitable for balancing “disk type” parts Although the machine is suitable for balancing disc-type workpieces, it is also suitable for balancing workpieces with two measuring surfaces.

The 97V300 can be equipped with a pneumatic or hydraulic collet clamping, which greatly increases productivity when balancing large batches of the same type of parts. The standard version of the machine has a conical seating of the spindle, which allows, with the help of balancing mandrels, to work with a large number of different parts.

The equipment has a monolithic case and a preresonant support that allows to work with heavy rotors. Spindle unit machine has high-precision bearings and a unique design that ensures high accuracy of unbalance determination (0.4 g*mm / kg). In addition, the spindle assembly is equipped with an electromagnetic spindle lock for easy unbalance correction and readjustment.

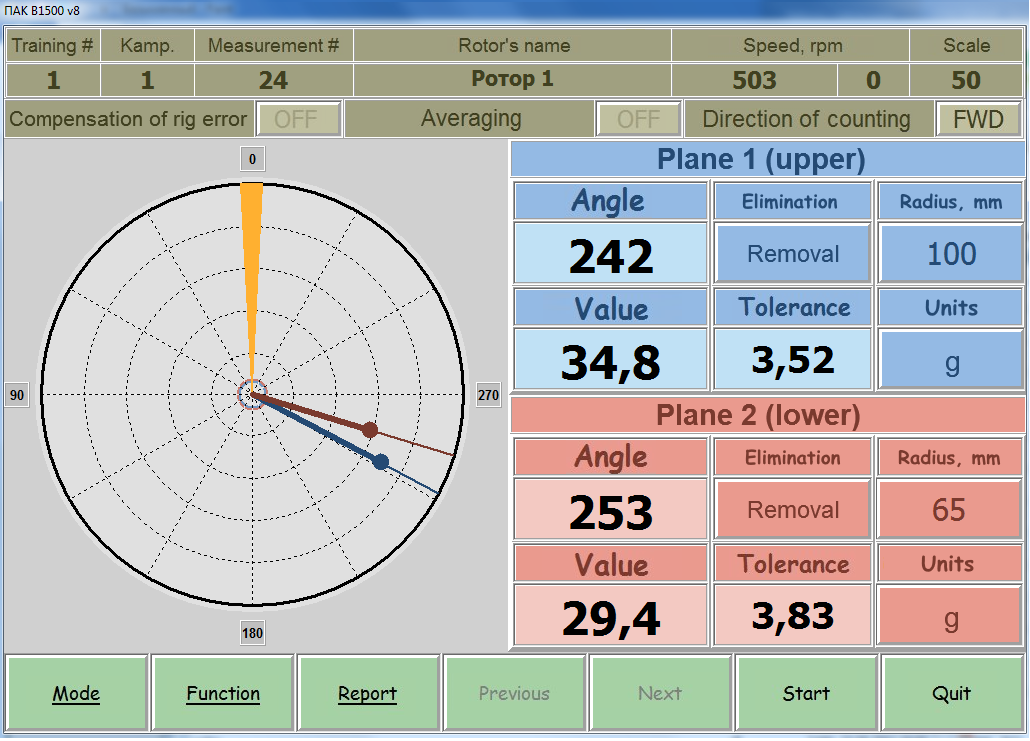

The machine is equipped with specially developed for this type of machine software PAK – V. The software supports the function of the tracking system providing control of the angular position of the spindle that allows you to instantly determine the position of the unbalance correction, as well as allows you to organize the function of automatic rotation of the part in a given angular position if necessary to adapt the equipment to work in an automatic production system in industries with mass production output.

The balancing machine is controlled by a “control desk” located in a separate control cabinet. There is also an industrial computer with touch screen controlling the hardware-software complex PAK-VERT. If necessary, it is possible to order the manufacture of a unique balancing system with the characteristics and functions specified by the customer.

The PAK-1V unbalance measuring unit is a 2-plane measuring balancing system for balancing disc-type rotors on vertical balancing machines. It can perform static (single-plane) balancing in dynamic mode on a two-plane balancing machine.

Based on an industrial fanless computer with a touchscreen and a multi-channel measuring unit, the system ensures reliability and a long service life, even under intensive use. The PAK-1V utilizes a universal measuring path and modern component base, allowing for equally high accuracy when working with all types of rotors.

Its intuitive interface, self-calibration capability, and automation of key operations make the complex a convenient tool for both experienced specialists and novice beginners.

|

Parameter |

Value |

|---|---|

|

Balancing rotors weight range, kg |

3 – 300 |

|

Maximum rotor diameter (over the bed), mm |

1000 |

|

Maximum rotor height, mm |

300 |

|

Machine type |

Hard-bearing |

|

Minimal achievable residual specific unbalance, gmm/kg |

4 |

|

Rotor rotation speed range, rpm |

300 – 1000 |

|

Number of measured rotor correction planes |

1 & 2 |

|

Electric motor power, kW |

7.5 |

|

Power supply parameters |

400V ± 10%, 3 Ph, 50Hz ± 1 |

|

Balancing system |

PAK-1V |

|

Overall machine dimensions (length x width x height), mm |

2500 x 1300 x 1800 |

|

Machine weight, kg |

1300 |

Leave a request and our manager will contact you to answer questions via your preferred messenger.