Home » Products » Garage equipment » DPF Cleaning Machines » POSEIDON-1000 Maxus

POSEIDON-1000 Maxus

Maximum performance DPF cleaning, all vehicle types, maximum features, top performance

220

Tank capacity, l

3-stage

Liquid filtration

Ultimate performance and features for demanding users

The machine allows you to max out the performance of DPF filter and catalyst cleaning for all types of cars without mechanical intervention.

The operating principle of the stand is based on the water hammer effect and the properties of turbulent fluid movement. In the cleaning process, special solutions and certain temperature conditions are met.

Poseidon functionality:

- The bench is designed for cleaning filters (DPF, FAP, GPF, SCR) and catalysts.

- The most functional among the foreign analogues, due to which it has a high performance.

- Automated operation and control of the cleaning and drying process of the filter.

- Set of adapters allows you to install any DPF filter, regardless of the brand of the car.

- Anti-frost system of the water system, insulation of pipes and tank. When it is not working temperature of liquid is controlled, liquid heating and pump is automatically switched on once per hour for pumping of liquid in the system.

- Automated cleaning process with programming of all operating modes.

- Full monitoring for cleaning and drying process.

- Fast installation with quick clamping adapter.

- Installation of any large filters with non-standard dimensions.

- Fully stainless steel working surfaces and stand body.

- Sealed chamber limits liquid splashing but also reduces noise level.

- Large volume cleaning fluid filters.

- Monitoring condition of the filtration system.

- Closed loop filtration system.

- Optimal tank volume and water autofill.

- Freestanding Control Panel.

- 17-inch touch screen monitor

- Operation & service personalized manuals

- Intuitive simple operationing

- High product reliability

- Safety options modifications

- Low-cost spare parts

- 12 months warranty

Mechanical Design

- Corrosion-resistant construction – The machine body and all working surfaces are manufactured entirely from stainless steel sheet, ensuring durability, reduced maintenance costs, and long service life.

- Ergonomic stand design – Provides easy access to the working area and internal components, minimizing downtime and lowering service expenses.

- Sealed cleaning chamber – Prevents fluid splashing, minimizes noise, and reduces cleaning area maintenance requirements.

- Optimized fluid tank volume – Ensures fast liquid heating and longer operation intervals, reducing resource consumption and operating costs.

Operator Comfort and Safety

- Illuminated work chamber – Built-in lighting improves visibility and accuracy of operations, reducing the chance of operator error.

- Ambient temperature control – Safety lock prevents operation in freezing conditions, protecting key systems and avoiding costly damage.

- Electrical protection system – Phase sequence and failure monitoring safeguard electrical components, lowering repair risks and extending equipment lifespan.

Fluid and Air Systems

- Closed-loop filtration system – A three-stage filtration with large-capacity filters maintains fluid quality, reducing consumable costs and frequency of fluid changes.

- Automatic water management – Integrated auto-fill and level control system maintains consistent performance with minimal operator intervention.

- Air pressure control – Stable pneumatic regulation ensures reliable operation and minimizes unexpected stoppages.

- Filtration system monitoring – Automatic notifications allow proactive maintenance, preventing downtime and costly breakdowns.

Control and Monitoring

- Industrial-grade control panel – A freestanding unit with a 17” touch screen PC on Windows OS ensures intuitive operation, reducing training time and operator error.

- Integrated reporting tools – Diagnostic and cleaning reports improve quality control, support traceability, and help reduce warranty claims.

Adaptability and Process Efficiency

- Universal adapter kit – Quick-clamping camlock adapters and specialized fixtures enable fast connection of various DPF filters, saving setup time and increasing productivity.

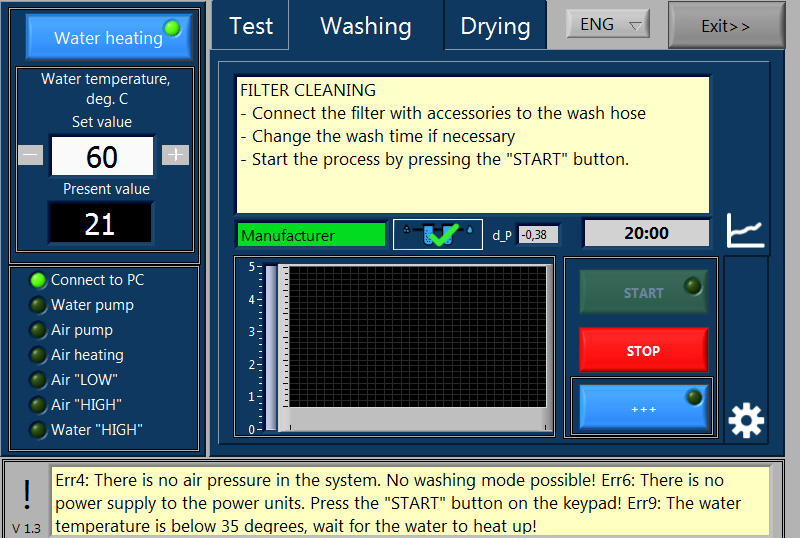

- Two-way cleaning capability – Automated forward and reverse cleaning modes improve efficiency, reducing the number of cycles and extending filter life.

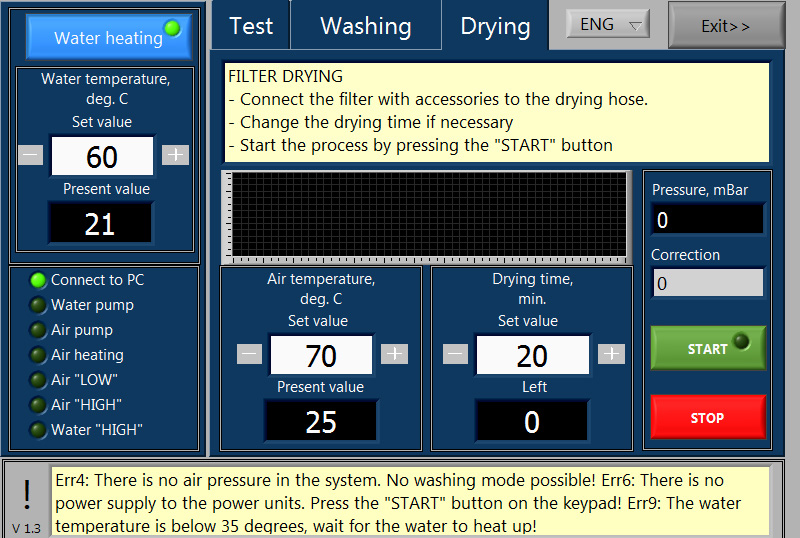

- Efficient drying system – A powerful hot air blower with heating element ensures complete moisture removal, speeding up turnaround time and increasing daily throughput.

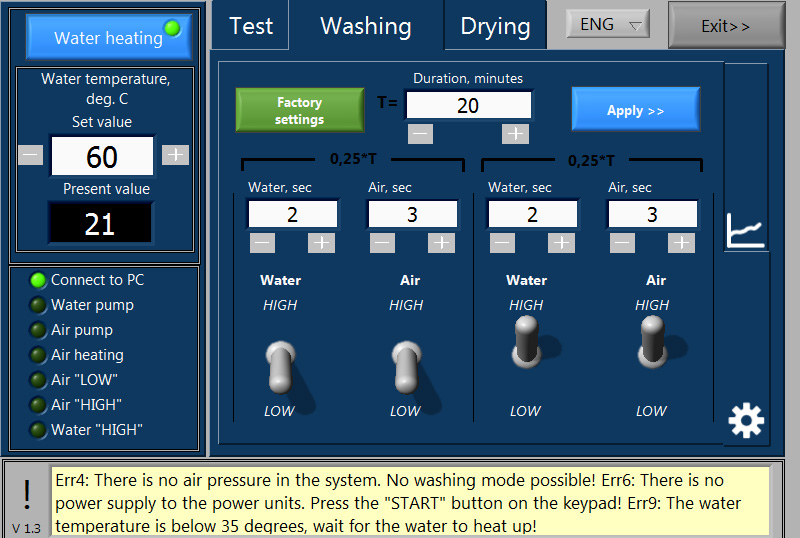

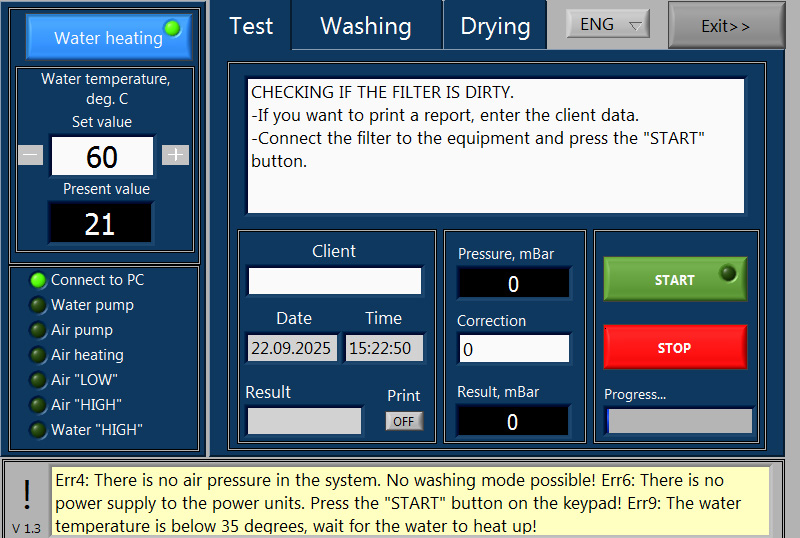

Poseidon-1000 Control System Overview

The Poseidon-1000 is equipped with an advanced operating mode control system designed to ensure precise, safe, and efficient operation throughout all stages of the DPF cleaning process.

A tab-based interface organizes the cleaning process into three dedicated modes — Testing, Washing, and Drying — each with tailored controls, parameter inputs, and live data displays. Built-in safety interlocks verify critical conditions before starting a cycle, preventing incorrect operation and ensuring reliable results.

The control panel enables direct management of key actuators, including water and air pumps, heaters, and valves, with real-time feedback on their operational state. Adjustable temperature settings with continuous monitoring and automatic safety shutdowns guarantee optimal cleaning conditions and equipment protection.

With precise control logic, robust safety features, and comprehensive monitoring capabilities, the Poseidon-1000 control system delivers consistent cleaning performance and simplifies the operator’s workflow.

Key Features — Control System Poseidon-1000

- Direct Actuator Control: Independent control of water and air pumps, heaters, and valves with real-time feedback on component status.

- Accurate Temperature Management: Adjustable water and air temperature setpoints with continuous monitoring and automatic shutdown at safety thresholds.

- Mode-Based Operation: Dedicated tabs for Testing, Washing, and Drying with tailored controls, parameter inputs, and live data visualization.

- Integrated Safety Interlocks: Continuous verification of water level, temperature, compressed air pressure, ambient temperature, and power supply before process start.

- Advanced Diagnostics and Error Handling: Clear fault codes with root-cause descriptions and corrective recommendations reduce troubleshooting time.

- Real-Time Process Visualization: Live graphs display key parameters such as pressure trends for better process monitoring.

- Configurable Cleaning Profiles: Adjustable cycle duration, pulse intervals, and flow reversal parameters to optimize cleaning for different filter types.

- Built-In Protocol Printing: Automatic generation of test reports with pre- and post-cleaning data for documentation and quality control.

- Emergency Stop and Safe Shutdown: Dedicated controls ensure rapid process termination and protect system components.

|

Parameter |

Value |

|---|---|

|

Inner chamber dimensions (length x width x height), mm |

1700 x 1000 x 1000 |

|

Tank capacity, l |

220 |

|

Working pneumatic pressure, bar |

6 |

|

Pump capacity, l/min |

200 |

|

Filtration of liquid |

3 levels, 30 – 200 microns |

|

Liquid temperature, °C |

40 – 90 |

|

Recommended working temperature, °C |

60 |

|

Drying temperature, °C |

80 – 130 |

|

Recommended drying temperature, °C |

100 |

|

Air system performance, m3/h |

290 |

|

Maximum pressure, mbar |

330 |

|

Sensors for liquid level and temperature | |

|

Maximum power, kW |

22 |

|

Power supply parameters |

400V ± 10%, 3 Ph, 50Hz ± 1 |

|

Overall machine dimensions (length x width x height), mm |

2780 x 1390 x 2230 |

|

Machine weight, kg |

600 |

- 4-pin universal adapter – 1 set.

- Expanding pneumatic adapter with a set of silicone inserts – 1 set.

- EURO-5 particulate filter washing adapter – 1 set.

- EURO-6 particulate filter washing adapter – 1 set.

- Pump for washing the machine chamber – 1 set.

- Camlock basic adapter set – 1 set.

- Silicone sleeves – 3 pcs.

- Metal hose with stainless steel braid. L – 1.5 m – 1 pc.

- Rubber hose L – 1.5 m – 1 pc.

- Rubber hose L – 0.8 m – 1 pc.

- Consumables starter pack – 1 pcs.

- Operation manual (in English) – 1 pc.

Watch the video review of our machine

This video provides a complete overview of the machine’s design, demonstrates its main operating stages, and shows the process of setup and maintenance. You will see how the equipment operates in real conditions and assess its ease of use.

Free support and training

Request Your Custom Equipment Offer Today

Take advantage of cost savings, unmatched service, and qualification enhancement