Home » Products » Universal Balancing Machine » Horizontal Balancing Machine » 9KW725

Soft-bearing heavy industry balancer up to 65000 kg. Combined drive

Maximal weight, kg

Maximal diameter, mm

Maximum length, mm

The machine has high accuracy (0,4 gmm \ kg). Accuracy is achieved due to the special design of the spindle and the rig of the machine, as well as a reliable balancing system, PAK-1, which has a high degree of noise immunity. Ease of control allows you to quickly learn how to work on the machine and get to work as soon as possible. When designing the machine, high demands were placed on the functionality and versatility of each node, this made it possible to install absolutely any driveshaft on the machine with a minimum of time.

Characteristic features of soft bearing balancing machines:

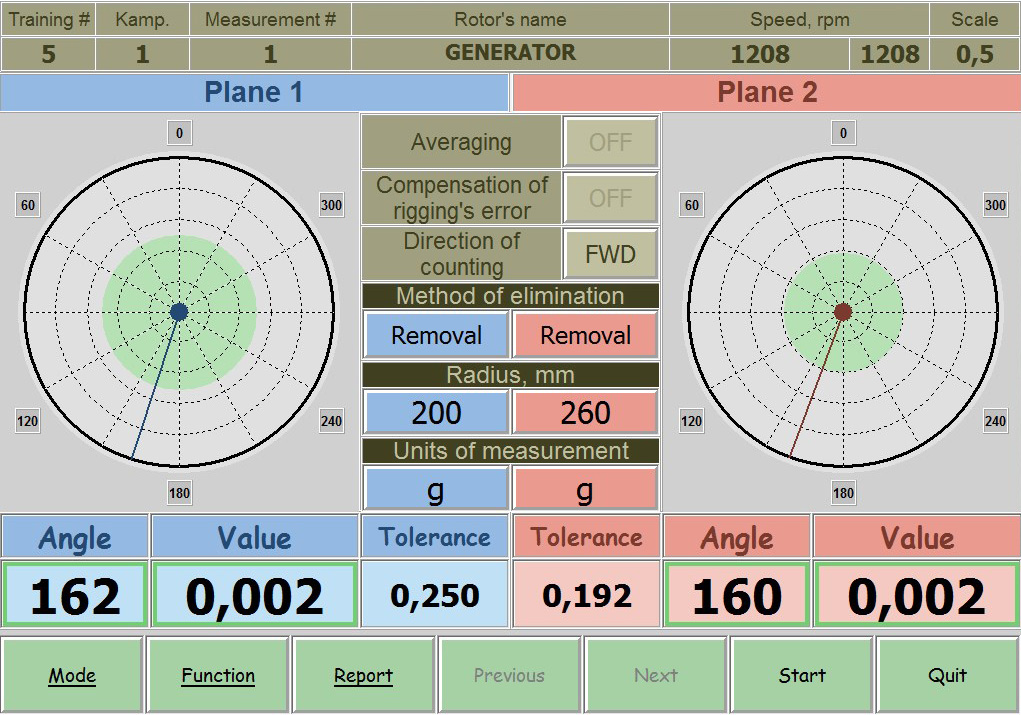

The PAK-1 unbalance measuring unit represents the latest generation of measuring complexes for dynamic balancing, combining high precision, stability, and ease of use. It’s designed to tackle a wide range of rotor balancing tasks, from simple to the most complex, requiring precise measurements.

Based on an industrial fanless computer with a touchscreen and a multi-channel measuring unit, the system ensures reliability and a long service life, even under intensive use. The PAK-1 utilizes a universal measuring path and modern component base, allowing for equally high accuracy when working with all types of rotors.

Its intuitive interface, self-calibration capability, and automation of key operations make the complex a convenient tool for both experienced specialists and beginners.

|

Parameter |

Value |

|---|---|

|

Balancing rotors weight range, kg |

6000 – 65 000 |

|

Maximum rotor diameter (over the bed), mm |

4000 |

|

Distance between rotor bearing journal centers, mm, min/max |

800 – 12 000 |

|

Rotor bearin journals diameter, mm |

100 – 550 |

|

Machine type |

Soft-bearing |

|

Support type |

Rollers |

|

Minimal achievable residual specific unbalance, gmm/kg |

1.0 |

|

Rotor rotation speed range, rpm |

150 – 400 |

|

Drive type |

Belt |

|

Electric motor power, kW |

90 |

|

Power supply parameters |

400V ± 10%, 3 Ph, 50Hz ± 1 |

|

Balancing system |

PAK-1 |

|

Overall machine dimensions (length x width x height), mm |

16 000 x 3000 x 3500 |

|

Machine weight, kg |

25000 |

Leave a request and our manager will contact you to answer questions via your preferred messenger.