Home » Products » Garage equipment » Driveshaft Repair Equipment » Driveshaft Balancing Machine » BVI-03-74

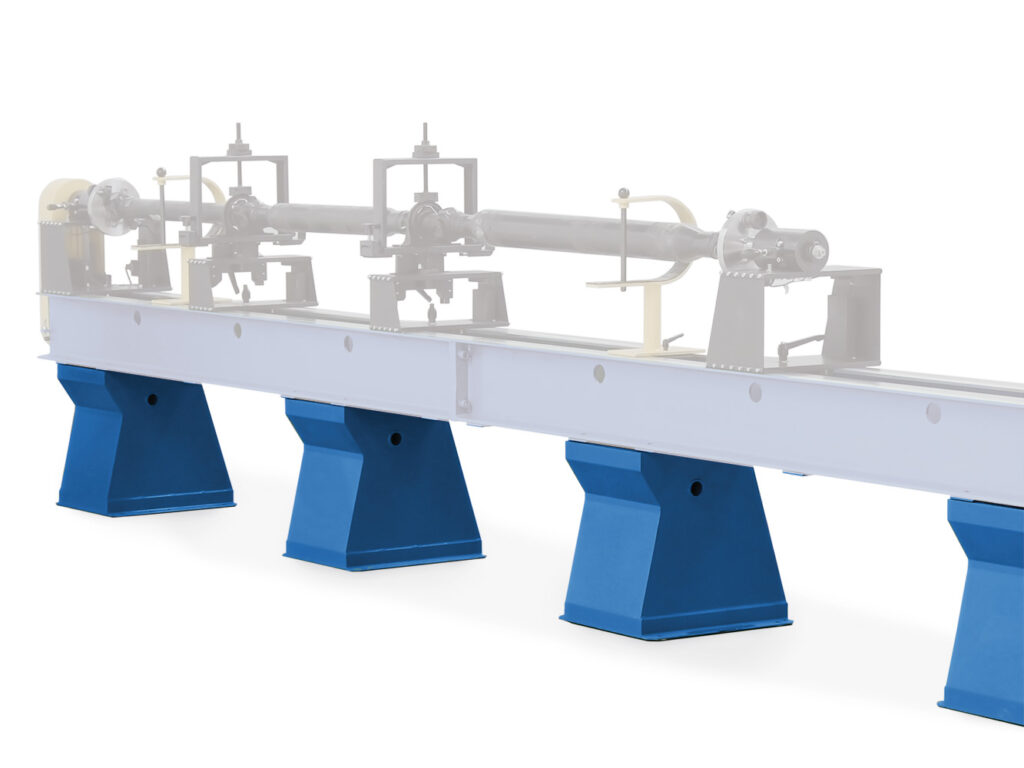

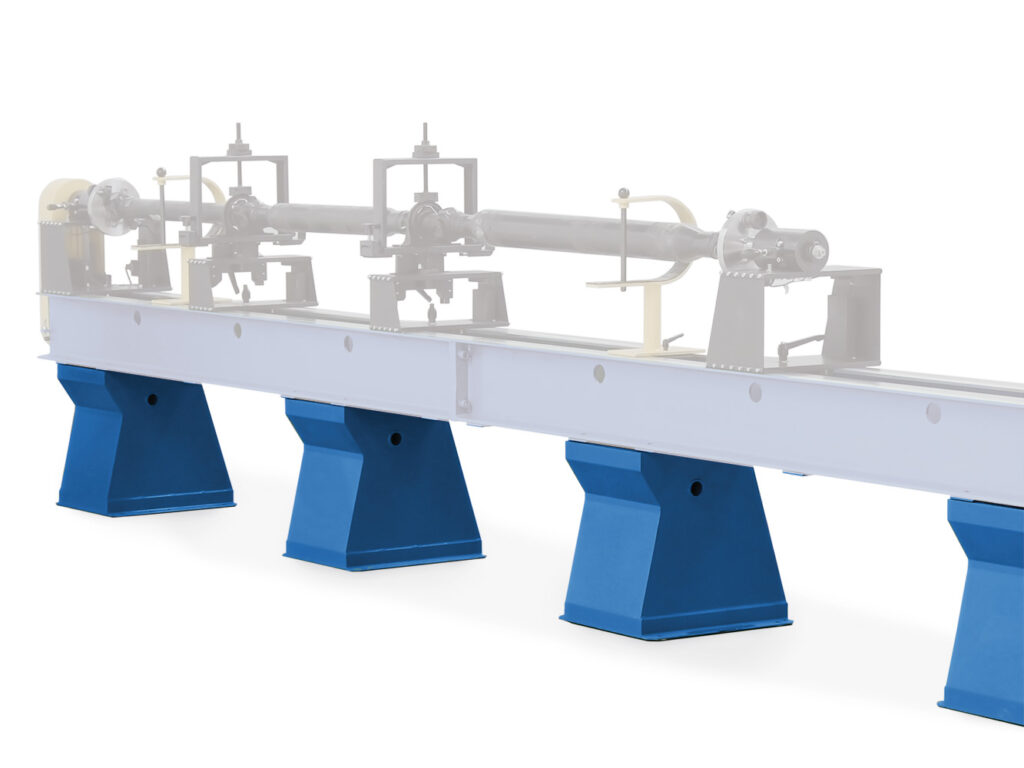

4-support driveshaft balancer for three-piece shafts, max 150kg, length up to 4800mm

Maximal weight, kg

Number of supports

Maximum length, mm

Driveshaft balancer BVI-03-74 has a high performance and is used to balance cardan/drive shafts of the cars and trucks up to 150 kg. Also, it makes the process of balancing the driveshaft simple thanks to many technical solutions, while the machine has an affordable price, which reduces your financial burden and allows your business to grow efficiently.

The machine has high accuracy (1 gmm \ kg). Accuracy is achieved due to the special design of the spindle and the rig of the machine, as well as a reliable balancing system, PAK-4, which has a high degree of noise immunity. Moreover, ease of control allows you to quickly learn how to work on the machine and get to work as soon as possible. When designing the machine, high demands were placed on the functionality and versatility of each node. So this made it possible to install absolutely any driveshaft on the machine with a minimum of time.

Machine support has a unique design which allows you to implement in fact three schemes for fixing outboard bearings. In addition, the height adjustment of the supports takes little time thanks to the unique design solution light height. Finally, unique technical modifications play important role in the process of quick readjustment of the machine and increasing the level of functionality of the equipment is played.

So far, quickly clamping adapters made by the patented EASY CLAMPR technology can save the time for reinstalling the driveshaft, which allowed the use of this machine not only in repair shops but also in serial and small-scale production.

The PAK-4 unbalance measuring unit is specially designed for cardan shaft balancing.

synchronous measurement in multiple planes saves time and simplifies the operator’s work.

The screen displays information about the welding location and correction weights for all planes at once.

Based on an industrial fanless computer with a touchscreen and a multi-channel measuring unit, the system ensures reliability and a long service life, even under intensive use. The PAK-4 utilizes a universal measuring path and modern component base, allowing for equally high accuracy when working with all types of rotors.

Its intuitive interface, self-calibration capability, and automation of key operations make the complex a convenient tool for both experienced specialists and beginners.

|

Parameter |

Value |

|---|---|

|

Balancing rotors weight range, kg |

1 – 150 |

|

Maximum rotor diameter, mm |

140 |

|

Maximum flange diameter, mm |

250 |

|

Maximum cardan shaft length, mm |

4700 |

|

Machine type |

Soft-bearing |

|

Number of simultaneously measured planes |

2, 3, 4 |

|

Minimal achievable residual specific unbalance, gmm/kg |

10 |

|

Rotor rotation speed range, rpm |

1000 – 2000 |

|

Drive type |

Asynchronous variable-frequency electric drive |

|

Electric motor power, kW |

2.2 |

|

Power supply parameters |

400V ± 10%, 3 Ph, 50Hz ± 1 |

|

Balancing system |

PAK-4 |

|

Overall machine dimensions (length x width x height), mm |

6200 x 1100 x 1500 |

|

Machine weight, kg |

700 |

Leave a request and our manager will contact you to answer questions via your preferred messenger.