Home » Products » Garage equipment » Driveshaft Repair Equipment » Driveshaft Balancing Machine » BVI-03-72

BVI-03-72

2-support driveshaft balancer for single-piece, max 100kg, length up to 2000mm

100

Maximal weight, kg

2

Number of supports

Perfect for small production, handles similar single-piece shafts

The BVI-03-72 specializes in balancing two propshafts and is designed for use in railroad repair depots. However, it is also capable of handling other types of universal joint shafts up to 100 kg in weight and length up to 2000 mm.

The machine has an accuracy of 10 g/kg, which makes it possible to balance driveshafts for heavy special equipment and industry. Thanks to this feature it is very popular in various production sectors. The versatility of the equipment makes it possible to work with a variety of products, which makes it in demand in repair services and workshops. High productivity allows to work with serial parts, which is especially useful for producers of special equipment and units, such as cardan shafts.

The equipment includes resonance-type vibration mounts with vibration sensors and spindle assemblies, as well as frames and a set of protective brackets. The rear support can move relative to the bed to work with gimbals of different lengths. The machine is controlled by a control panel, which is part of a separate control cabinet. The cabinet also contains a frequency converter for stepless speed control of the motor and optimal speed setting to bypass “resonance frequencies” that can affect the quality of balancing.

Unbalance detection is performed by converting the vibrations of the supports into a digital signal by means of vibration sensors and reading the speed of the driveshaft by a photoresistive speed sensor, which converts it into electronic pulses. Signals from the sensors go to the computing unit of the balancing system and are displayed on the screen of the microprocessor balancing device located on the control panel in a convenient form for the operator’s perception.

- The machine is operated by one person thanks to the spindle lock and safety brackets, which limit the rotation of the tooling and provide additional support when installing the gimbal;

- Patented “EASY CLAMP” adapter design ensures quick changeover of the machine (fixation of the flange in 10 seconds);

- The resonant supports enable a clear demonstration of the balancing quality using only human tactile sensations;

- Electric motor with a large power reserve guarantees trouble-free operation of the machine’s electric drive for many years.

Specialized Single-piece Shaft Design

- Soft-bearing support system optimized for driveshafts – Specialized soft-bearing design provides exceptional measurement sensitivity for automotive and truck driveshafts with masses from 3-100kg. The soft-bearing approach enables precise detection of driveshaft unbalances while accommodating the unique dynamic characteristics of cardan shaft assemblies.

- “Light Height”® adjustment system – Patented height adjustment mechanism enables rapid support positioning with minimal time requirements. The unique design solution allows quick adaptation to different driveshaft bearing configurations while maintaining measurement precision.

- Spindle retainer system – Integrated spindle locking mechanism secures spindle position during driveshaft installation, enabling single-operator setup procedures. The retainer system doubles section productivity by eliminating need for additional personnel during mounting operations.

- Dual-purpose protective bracket – Innovative protective bracket design serves both safety and operational functions, providing additional support during driveshaft installation. The dual-purpose approach maximizes utility while maintaining comprehensive safety protection.

- Extended length accommodation – Machine design accommodates driveshafts up to 2000mm length, enabling handling of extended truck and commercial vehicle applications. The extended capacity ensures compatibility with diverse automotive and heavy-duty vehicle requirements.

Advanced Driveshaft Clamping Systems

- Patented “EASY CLAMP”® technology – Revolutionary fast clamping adapters reduce driveshaft installation time by 50% through innovative design eliminating bolt-based mounting. The 5-second clamping capability enables rapid changeover between different driveshaft types for maximum productivity.

- Universal quick-clamping adapters – Primary adapter system utilizes centering rings manufactured on standard lathes to accommodate most common driveshaft configurations. The universal design eliminates need for extensive adapter inventories while providing precise centering for accurate measurements.

- Centering ring system – Specialized centering rings ensure precise driveshaft positioning within adapters for consistent measurement accuracy. The ring system accommodates diverse flange geometries while maintaining optimal concentricity throughout the balancing process.

Comprehensive Adapter Configuration System

- KV flange adapters for truck applications – Specialized adapters accommodate cross-tooth flanges in four standard sizes (120mm, 150mm, 180mm, 205mm) commonly used in truck driveshaft applications. The dedicated truck adapter system ensures compatibility with heavy-duty commercial vehicle requirements.

- Slotted adapters for diverse flanges – Versatile slotted adapter design accommodates various flanges with holes using the same centering ring principle as universal adapters. This configuration provides mounting flexibility for specialized and non-standard driveshaft designs.

Driveshaft-Optimized Drive System

- High-performance frequency-controlled drive – 1.5kW electric motor with power reserve reduces acceleration and braking times for driveshaft applications while providing adequate torque across the 3-100kg range. Frequency inverter enables smooth speed regulation across 1000-2000 rpm range optimized for driveshaft balancing requirements.

- Variable acceleration and braking modes – Drive system incorporates selectable acceleration and braking modes to optimize cycle times for different driveshaft types and weights. This flexibility maximizes productivity while ensuring safe operation across diverse cardan shaft applications.

- Extended speed range capability – Higher operational speed range (up to 2000 rpm) accommodates lightweight driveshafts requiring elevated balancing speeds for optimal measurement sensitivity. The extended range provides flexibility for various automotive and truck driveshaft applications.

Specialized PAK-1 Control System Integration

- Driveshaft-optimized PAK-1 control system – Specialized control system designed specifically for cardan shaft balancing applications with features tailored to driveshaft workshop requirements. The optimization ensures maximum efficiency and ease of use in automotive repair environments.

- Automatic and manual operational modes – Control system provides both automatic measurement completion and manual operator control modes. The automatic capability enables operator multitasking during measurement cycles for enhanced workshop productivity.

- Real-time process monitoring – System displays balancing process in real-time with driveshaft-specific unbalance behavior monitoring for optimal results. The monitoring capability enables operator optimization of balancing procedures for diverse driveshaft types.

- High-precision measurement system – 1.0 gmm/kg accuracy specification ensures precise unbalance detection for automotive and truck driveshaft applications. The precision capability accommodates demanding driveshaft balance requirements while maintaining productivity.

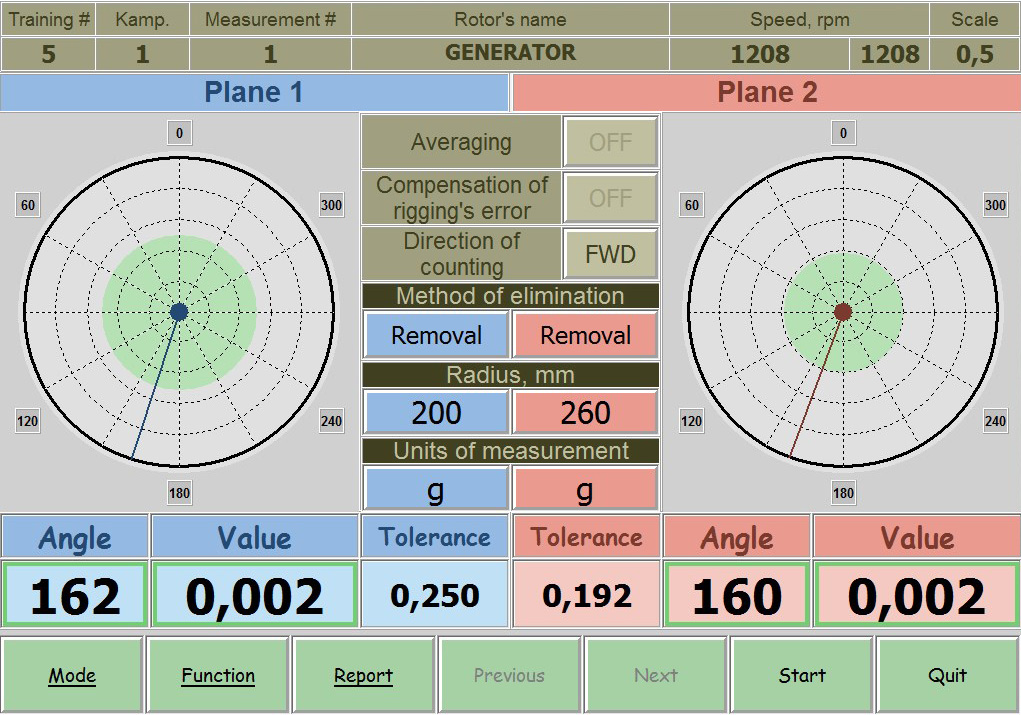

The PAK-1 unbalance measuring unit represents the latest generation of measuring complexes for dynamic balancing, combining high precision, stability, and ease of use. It’s designed to tackle a wide range of rotor balancing tasks, from simple to the most complex, requiring precise measurements.

Based on an industrial fanless computer with a touchscreen and a multi-channel measuring unit, the system ensures reliability and a long service life, even under intensive use. The PAK-1 utilizes a universal measuring path and modern component base, allowing for equally high accuracy when working with all types of rotors.

Its intuitive interface, self-calibration capability, and automation of key operations make the complex a convenient tool for both experienced specialists and beginners.

Features of the PAK-1 System:

- High-precision dynamic balancing for rotors of any configuration.

- Industrial fanless PC with touchscreen and multi-channel measuring unit.

- Setup using trial runs with calibration weights on production rotors.

- Self-calibration by the operator, eliminating annual service adjustment costs.

- Calculation of permissible unbalance values, even without technical documentation.

- Determination of control weight mass to simplify setup for a specific rotor.

- Real-time display of unbalance magnitude and angular position, including “highlighting” of the correction zone.

- Automatic measurement start upon reaching a set speed and automatic stop after cycle completion.

- Display of unbalance magnitude in grams, gmm, gcm, gmm/kg.

- Vector and exponential averaging for working with moving elements and in noisy conditions.

- Additional functions that significantly simplify the balancing process and expand the technological capabilities of the balancing machine.

- Generation and printing of balancing reports directly from the system.

- USB ports and Ethernet interfaces for connecting a printer, data storage, and integration into a local network.

|

Parameter |

Value |

|---|---|

|

Balancing rotors weight range, kg |

1 – 100 |

|

Maximum rotor diameter, mm |

140 |

|

Maximum flange diameter, mm |

250 |

|

Maximum cardan shaft length, mm |

2000 |

|

Machine type |

Soft-bearing |

|

Number of simultaneously measured planes |

2 |

|

Minimal achievable residual specific unbalance, gmm/kg |

10 |

|

Rotor rotation speed range, rpm |

1000 – 2000 |

|

Drive type |

Asynchronous variable-frequency electric drive |

|

Electric motor power, kW |

2.2 |

|

Power supply parameters |

400V ± 10%, 3 Ph, 50Hz ± 1 |

|

Balancing system |

PAK-1 |

|

Overall machine dimensions (length x width x height), mm |

3400 x 1100 x 1500 |

|

Machine weight, kg |

500 |

-

- Universal cam clamping adapters for driveshafts with a flanges diameter ranging from 90 mm to 125 mm – 2 pcs

- The centering ring to the universal adapter for driveshafts installation of of the car Sprinter W906 – 2 pcs

- The special-purpose adapter for cargo drive shaft flanges with diameters up to 250 mm – 2 pcs

- KV flange adapters are used to balance shafts with cross-tooth flanges and are typically applied to truck driveshafts with flange sizes of 120, 150, 180, and 205 mm – 2 pcs

- The operation manual on the machine with acceptance tests reports and the basic electric circuit – 1 pc

- The operation manual on balancing system – 1 pc

There are no options for this machine

Free support and training

Request Your Custom Equipment Offer Today

Take advantage of cost savings, unmatched service, and qualification enhancement