Home » Products » Universal Balancing Machine » Horizontal Balancing Machine » 9D717

Hard-bearing balancing machine wide range of rotors weighing up to 1500 kg

Maximal weight, kg

Maximal diameter, mm

Maximum length, mm

9D717 is an universal dynamic balancing machine with horizontal axis of rotation type. Generally, It is possible to balance the following kinds on such a machine:

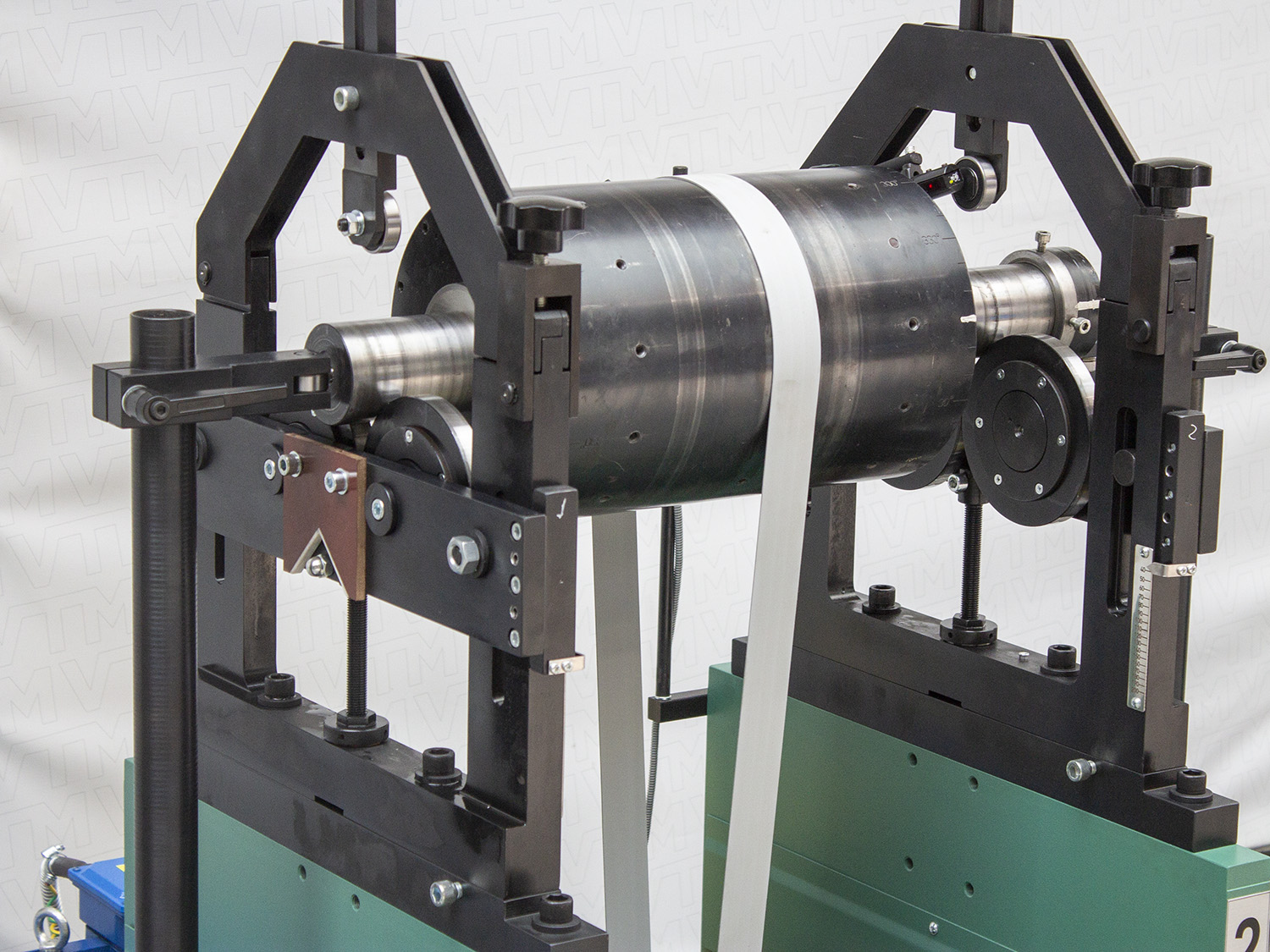

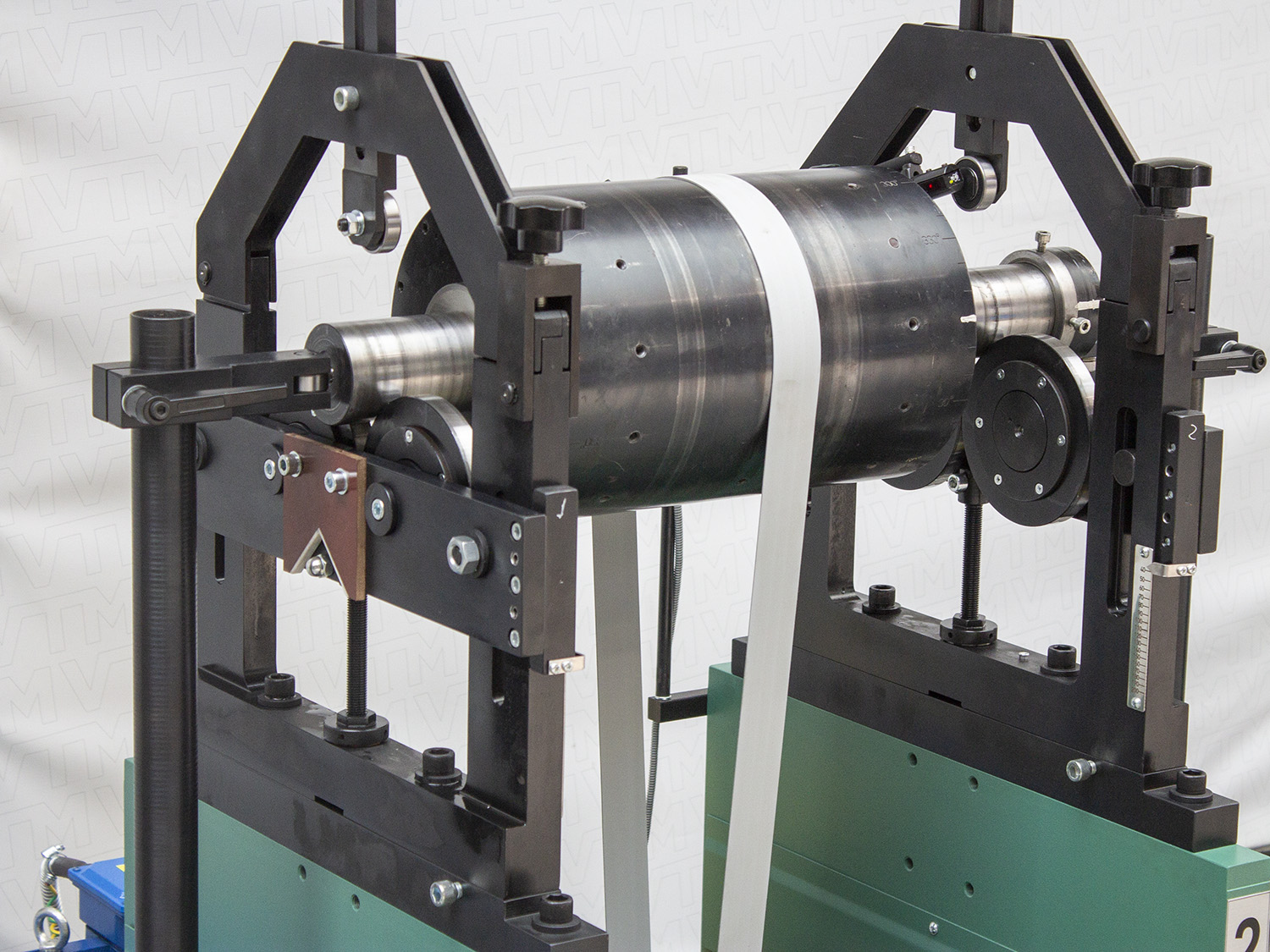

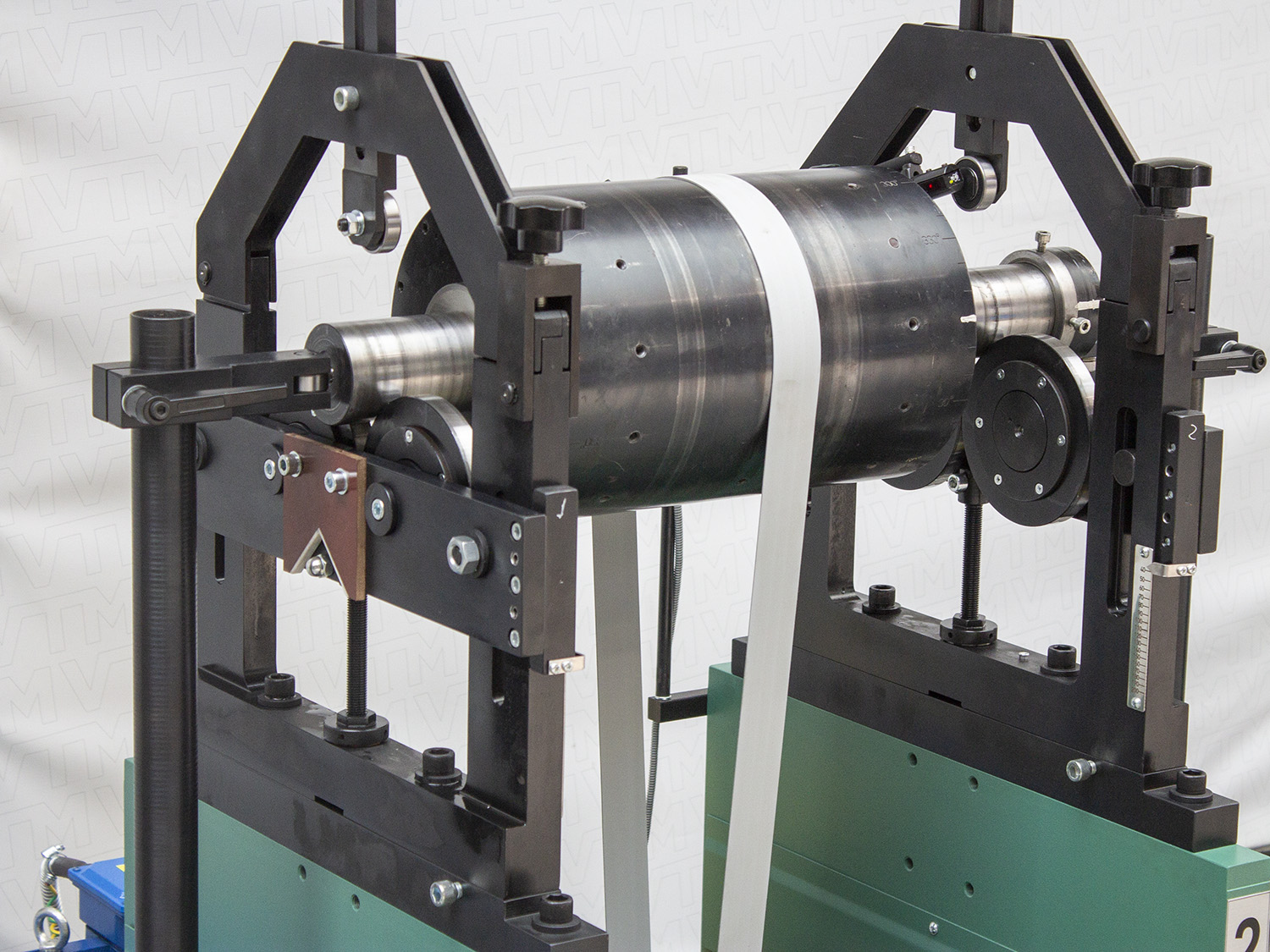

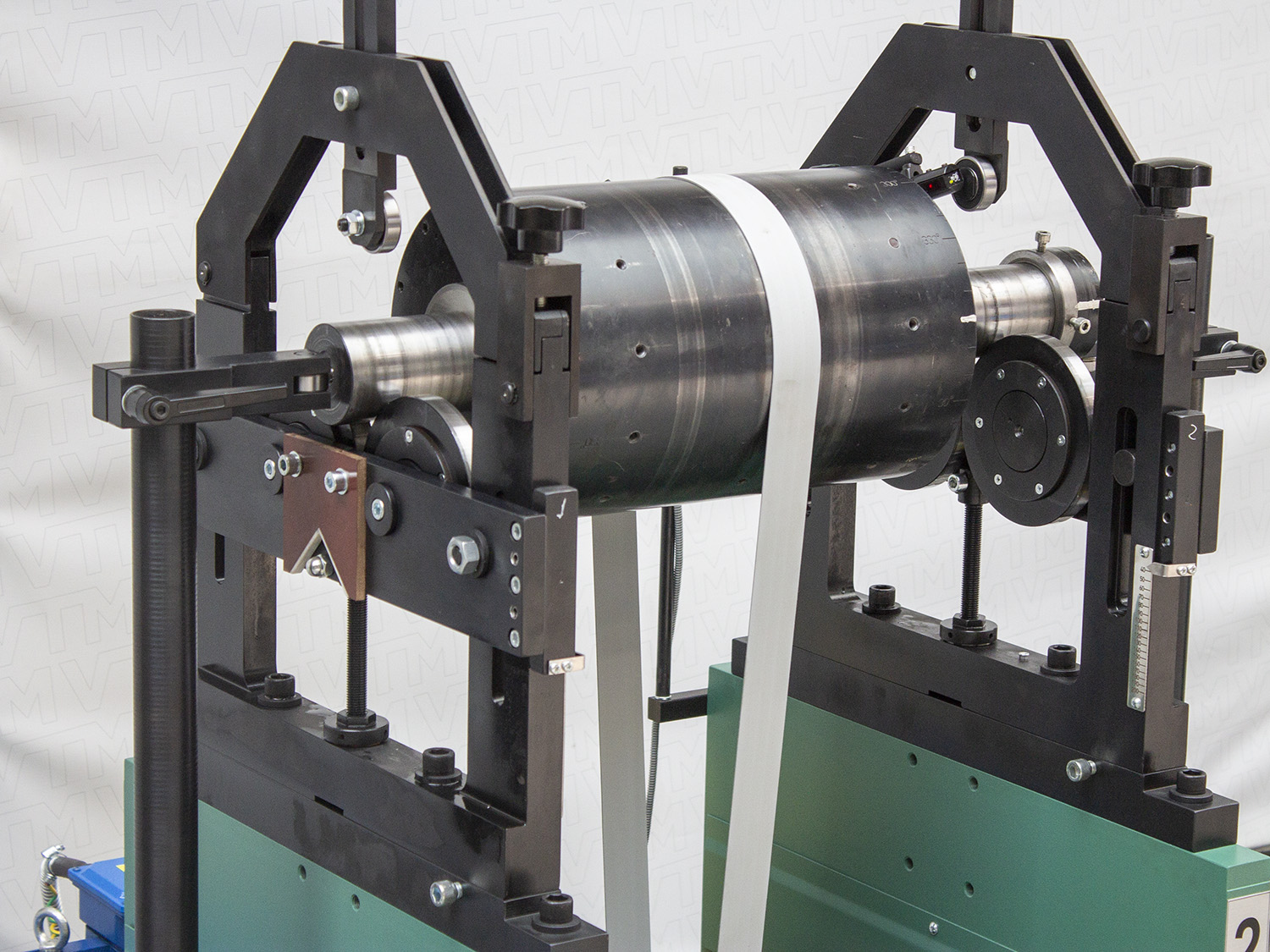

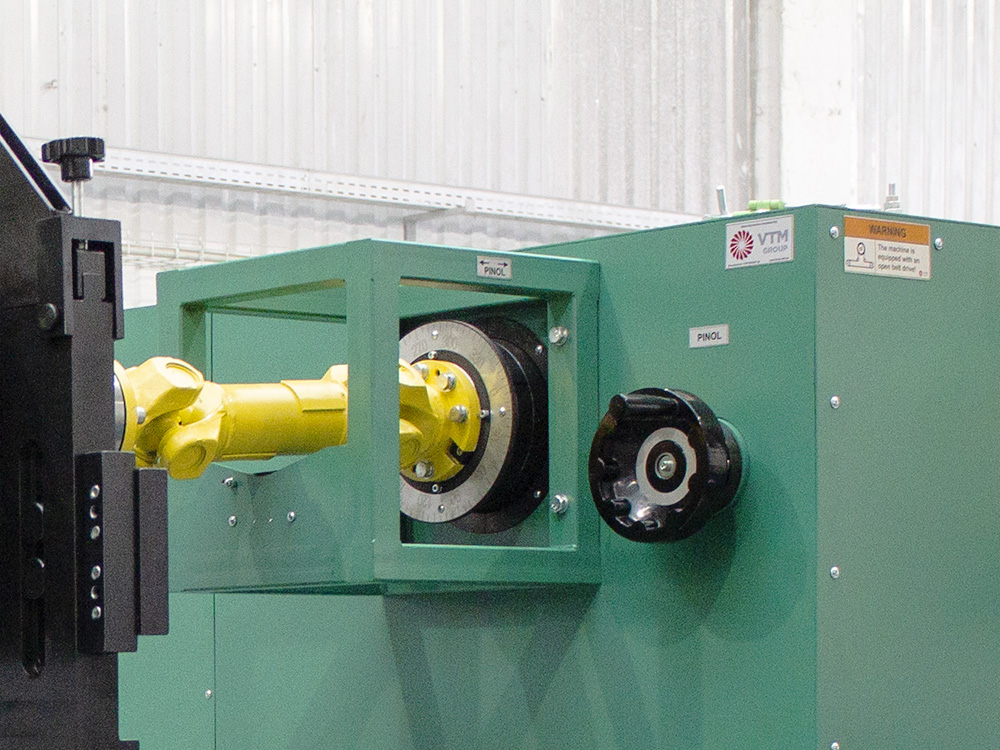

Thanks to the narrow stands and belt drive, the balancing machine 9D717 is used for balancing of rotors of various structures at repair and production plants.

The machine has high accuracy (0,4 gmm \ kg). Accuracy is achieved due to the special design of the spindle and the rig of the machine, as well as a reliable balancing system, PAK-1, which has a high degree of noise immunity. Ease of control allows you to quickly learn how to work on the machine and get to work as soon as possible. When designing the machine, high demands were placed on the functionality and versatility of each node, this made it possible to install absolutely any driveshaft on the machine with a minimum of time.

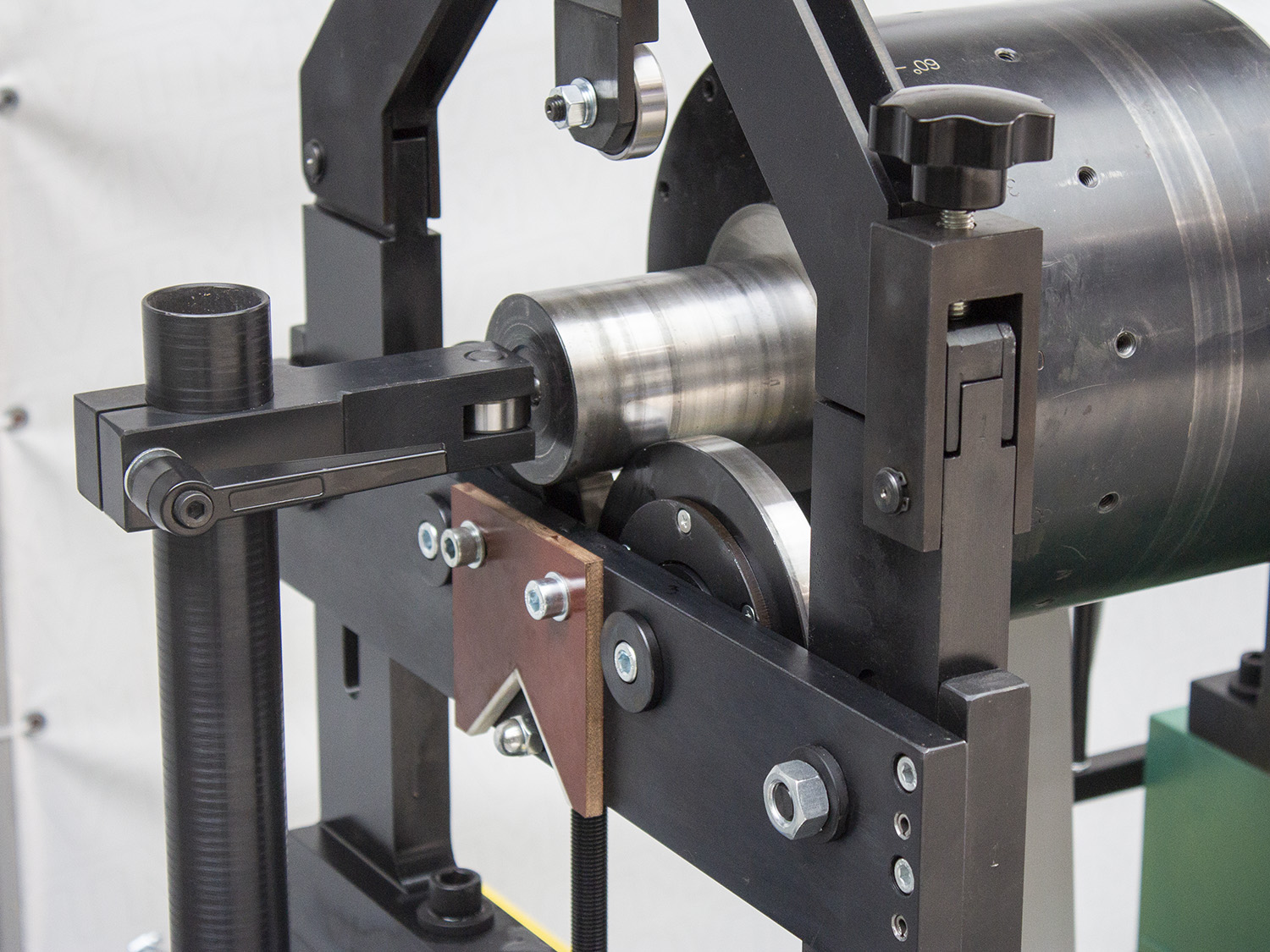

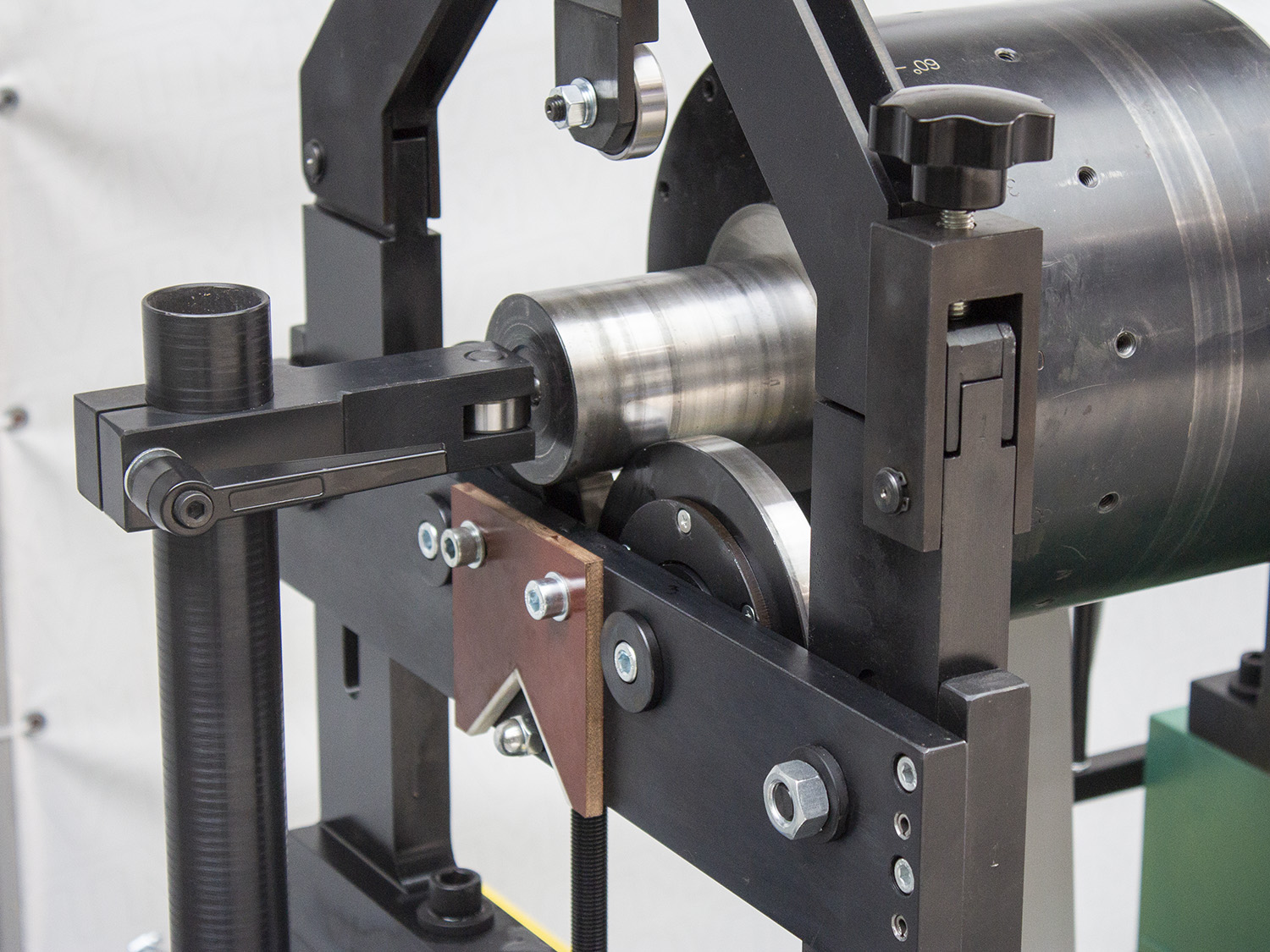

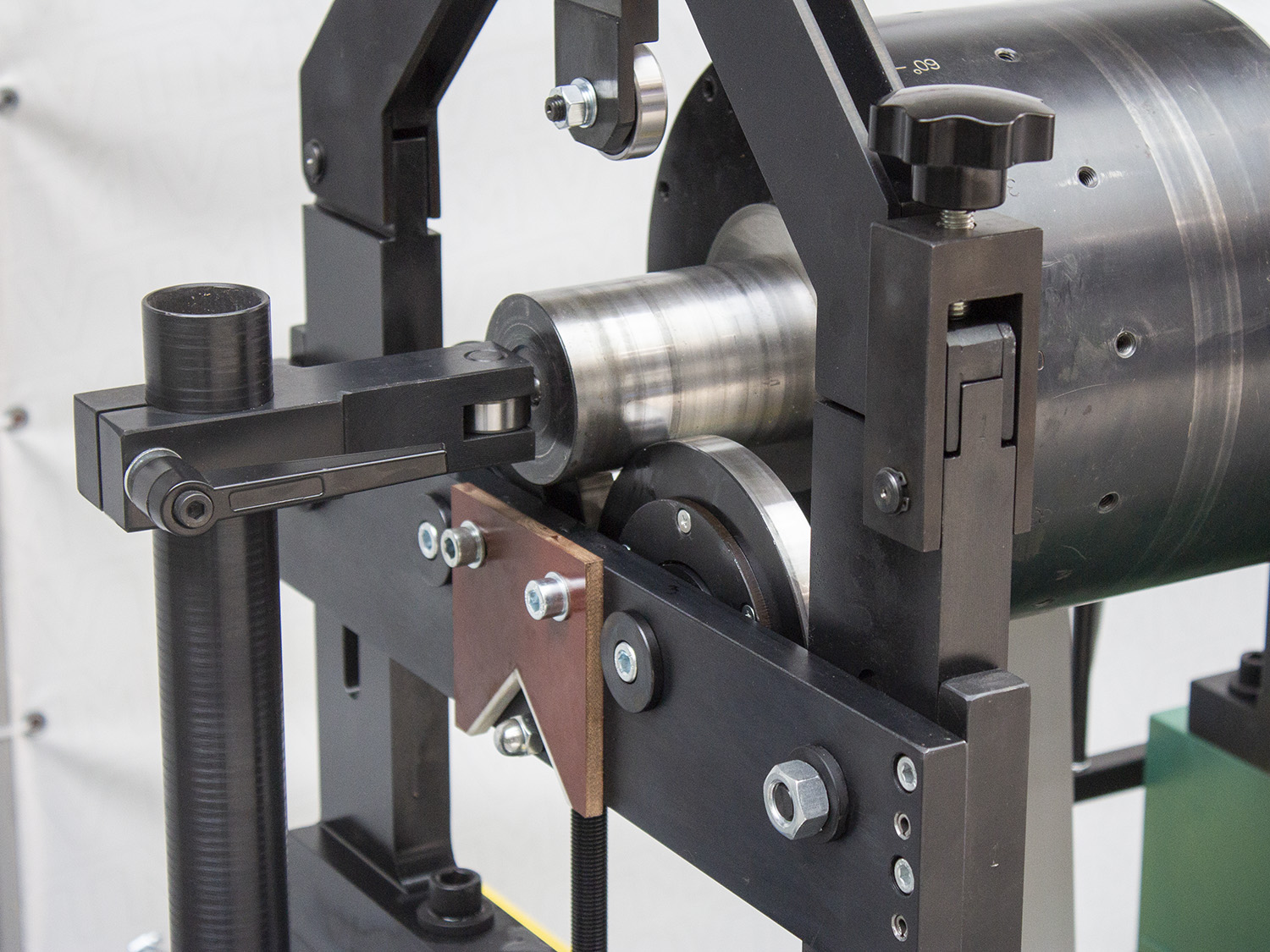

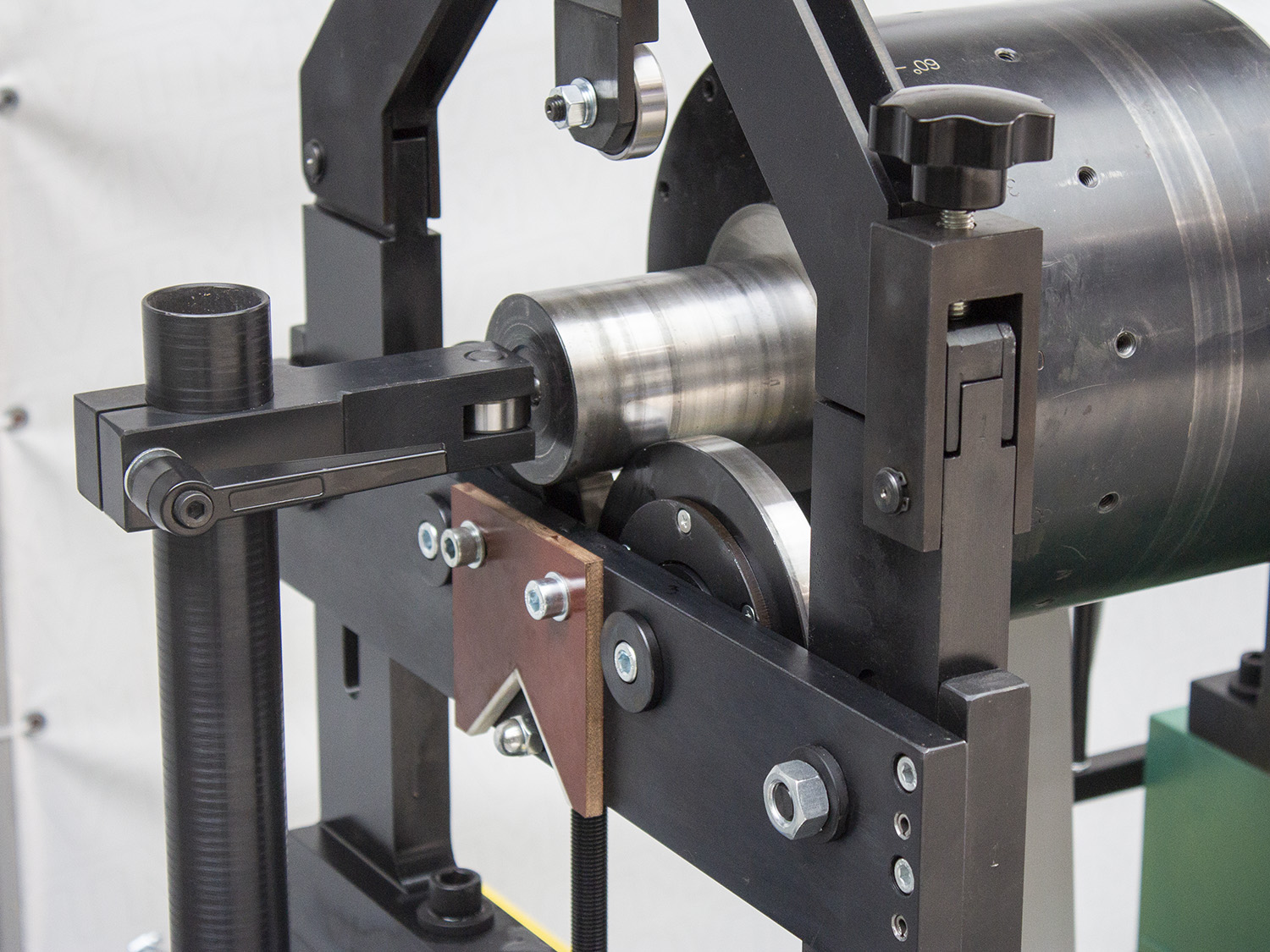

Width of the support rollers and roller cartridges allows the rotor to be installed with a very short length. Highly located “roller cassettes” allow you to create products with different overall dimensions, and the modular design allows you to increase the standard dimensions of the machine due to spacers and accessories.

Support has the ability to adjust the “roller block” in height, this allows you to balance the rotor with different diameters of the support journals, and also allows you to center the rotor when setting up the machine.

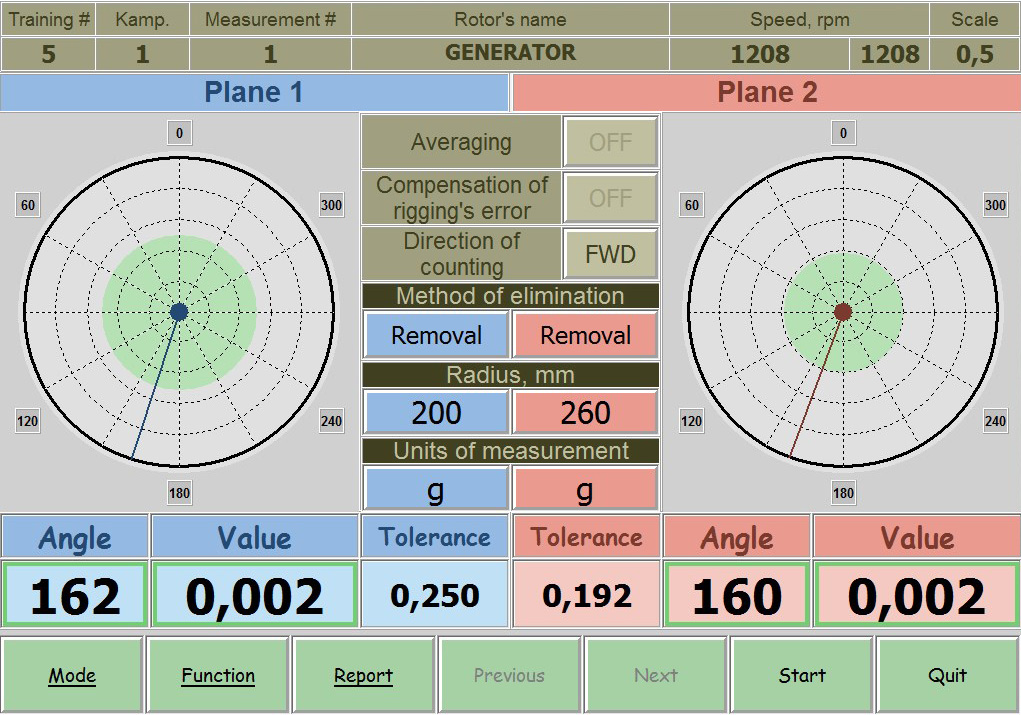

The PAK-1 unbalance measuring unit represents the latest generation of measuring complexes for dynamic balancing, combining high precision, stability, and ease of use. It’s designed to tackle a wide range of rotor balancing tasks, from simple to the most complex, requiring precise measurements.

Based on an industrial fanless computer with a touchscreen and a multi-channel measuring unit, the system ensures reliability and a long service life, even under intensive use. The PAK-1 utilizes a universal measuring path and modern component base, allowing for equally high accuracy when working with all types of rotors.

Its intuitive interface, self-calibration capability, and automation of key operations make the complex a convenient tool for both experienced specialists and beginners.

|

Parameter |

Value |

|---|---|

|

Balancing rotors weight range, kg |

15 – 1500 |

|

Maximum rotor diameter (over the bed), mm |

1800 |

|

Distance between rotor bearing journal centers, mm, min/max |

360 – 3000 |

|

Rotor bearin journals diameter, mm |

40 – 230 |

|

Machine type |

Hard-bearing |

|

Support type |

Rollers |

|

Minimal achievable residual specific unbalance, gmm/kg |

0.4 |

|

Rotor rotation speed range, rpm |

250 – 1200 |

|

Drive type |

Belt |

|

Electric motor power, kW |

7.5 |

|

Power supply parameters |

400V ± 10%, 3 Ph, 50Hz ± 1 |

|

Balancing system |

PAK-1 |

|

Overall machine dimensions (length x width x height), mm |

3500 x 1260 x 1500 |

|

Machine weight, kg |

1700 |

Your questions — our technical solutions

The 9D717 is an industrial-class model designed for handling large-scale assemblies. Its application range covers key sectors:

Energy: Steam and gas turbine rotors, generator rotors.

Mining Industry: Winch drums, crusher components, heavy-duty augers.

Petrochemicals: Centrifugal compressor shafts, large pump impellers.

Ventilation Systems: Industrial smoke exhausters and axial fans with a diameter of up to 1800 mm.

Shipbuilding and Railways: Propeller shafts and locomotive traction motors.

Yes, the 9D717 is designed to work with parts weighing up to 1500 kg. Its rigid hard-bearing design allows for mounting massive rotors without the risk of support deformation. High load capacity combined with sensor sensitivity enables effective unbalance elimination on both heavy and relatively light parts (from 15 kg).

In the basic configuration, the machine accommodates rotors with a distance between bearing journals of up to 3000 mm. For working with longer shafts, an extended bed option is provided. We can manufacture a bed of the required length to suit your specific production tasks, while ensuring perfect alignment and rigidity along the entire length of the equipment.

The machine achieves a minimum specific residual unbalance of 0.4 g·mm/kg. For equipment of this capacity, this guarantees compliance with the strictest standards, allowing for balancing to accuracy classes G1 and G2.5 (according to ISO 21940). This is critical for preventing premature bearing wear in heavy-duty machinery.

Yes, the machine is set up for a new product type by the operator using trial runs with calibration weights.

This approach offers several key advantages for B2B production:

Maximum Sensitivity: Calibration allows adapting the measuring system to the specific geometry and mass of the rotor, minimizing error.

Accuracy Control: The operator can verify and confirm measurement accuracy at any time, eliminating the accumulation of errors during long-term operation.

Flexibility: The machine maintains reference-level accuracy even with non-standard or complex parts, as the system is tuned to the actual response of the specific rotor.

Leave a request and our manager will contact you to answer questions via your preferred messenger.