Home » Products » Universal Balancing Machine » Vertical Balancing Machine » 97V50

Vertical balancer for medium rotors up to 50kg, enhanced stability, workshop-friendly

Maximal weight, kg

Maximal diameter, mm

Maximum height, mm

Special equipment model 97V50 – vertical balancing machine for single-plane rotors weighing up to 50 kg. Can be used in repair shops and production plants with different product series.

It is possible to balance such parts on the machine:The 97V50 has a rigid monolithic housing with an integrated preresonant vibration pylon on which the spindle assembly and electric drive are mounted. The spindle assembly has a tapered fit to achieve high alignment of the tooling with the rotary axis without the need for an indicator stand when adjusting.

The control is carried out through the control panel placed on the extendable stand attached to the housing. The control cabinet contains a frequency converter for smooth regulation of the electric drive and protection of electrical equipment. There is also a balancing system in the control cabinet.

There are two off-the-shelf options for selecting a balancing system: PB-02M (microprocessor-based system) and PAK-V (computer-based system with touch screen). It is also possible to make a special system according to the customer’s request.

A standard spindle with a tapered bore is used to mount a mandrel and attach a balancing part by means of a clamping bolt. This design is ideal for one-off and overhaul production with small batch balancing of various parts. For high production efficiency, the machine can be equipped with a hydraulically or pneumatically operated collet clamping device. Re-positioning a part on a machine with this modification takes approximately 3 seconds. The collet clamp can be controlled by a control panel or a foot pedal.

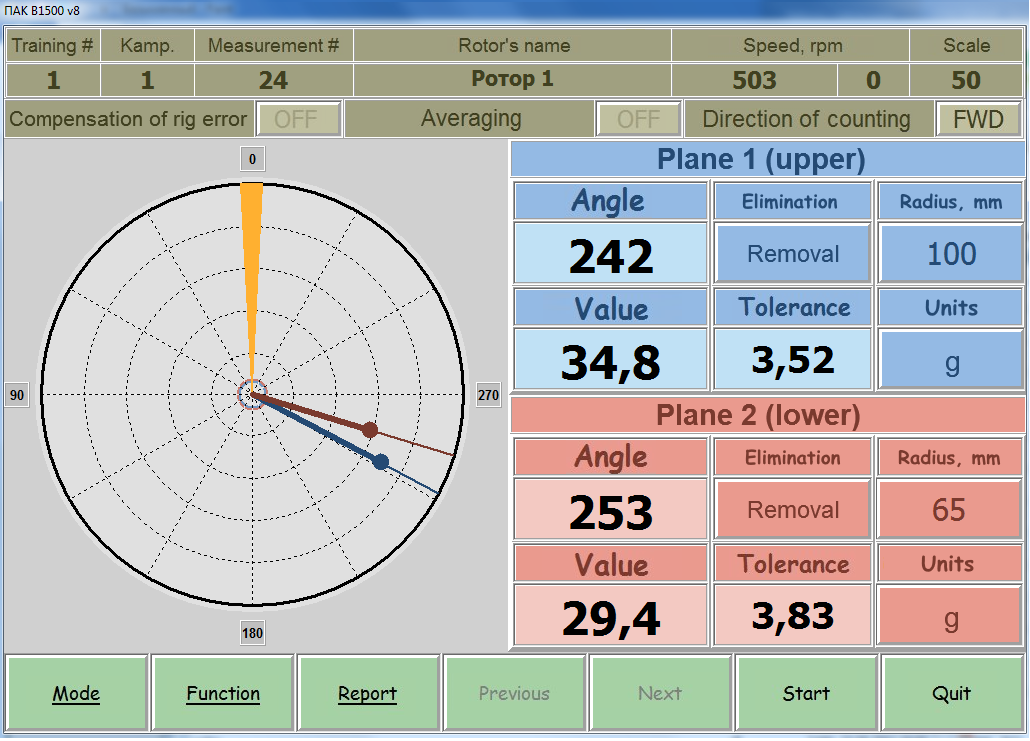

The PAK-1V unbalance measuring unit is a 2-plane measuring balancing system for balancing disc-type rotors on vertical balancing machines. It can perform static (single-plane) balancing in dynamic mode on a two-plane balancing machine.

Based on an industrial fanless computer with a touchscreen and a multi-channel measuring unit, the system ensures reliability and a long service life, even under intensive use. The PAK-1V utilizes a universal measuring path and modern component base, allowing for equally high accuracy when working with all types of rotors.

Its intuitive interface, self-calibration capability, and automation of key operations make the complex a convenient tool for both experienced specialists and novice beginners.

|

Parameter |

Value |

|---|---|

|

Balancing rotors weight range, kg |

0.5 – 50 |

|

Maximum rotor diameter (over the bed), mm |

550 |

|

Maximum rotor height, mm |

200 |

|

Machine type |

Hard-bearing |

|

Minimal achievable residual specific unbalance, gmm/kg |

4 |

|

Rotor rotation speed range, rpm |

300 – 1000 |

|

Number of measured rotor correction planes |

1 & 2 |

|

Electric motor power, kW |

3 |

|

Power supply parameters |

400V ± 10%, 3 Ph, 50Hz ± 1 |

|

Balancing system |

PAK-1V |

|

Overall machine dimensions (length x width x height), mm |

1800 x 1100 x 1500 |

|

Machine weight, kg |

700 |

Leave a request and our manager will contact you to answer questions via your preferred messenger.