Home » Products » Universal Balancing Machine » Vertical Balancing Machine » 97V10

Vertical balancing machine for rotors up to 10kg, compact design, space-efficient operation

Maximal weight, kg

Maximal diameter, mm

Maximum height, mm

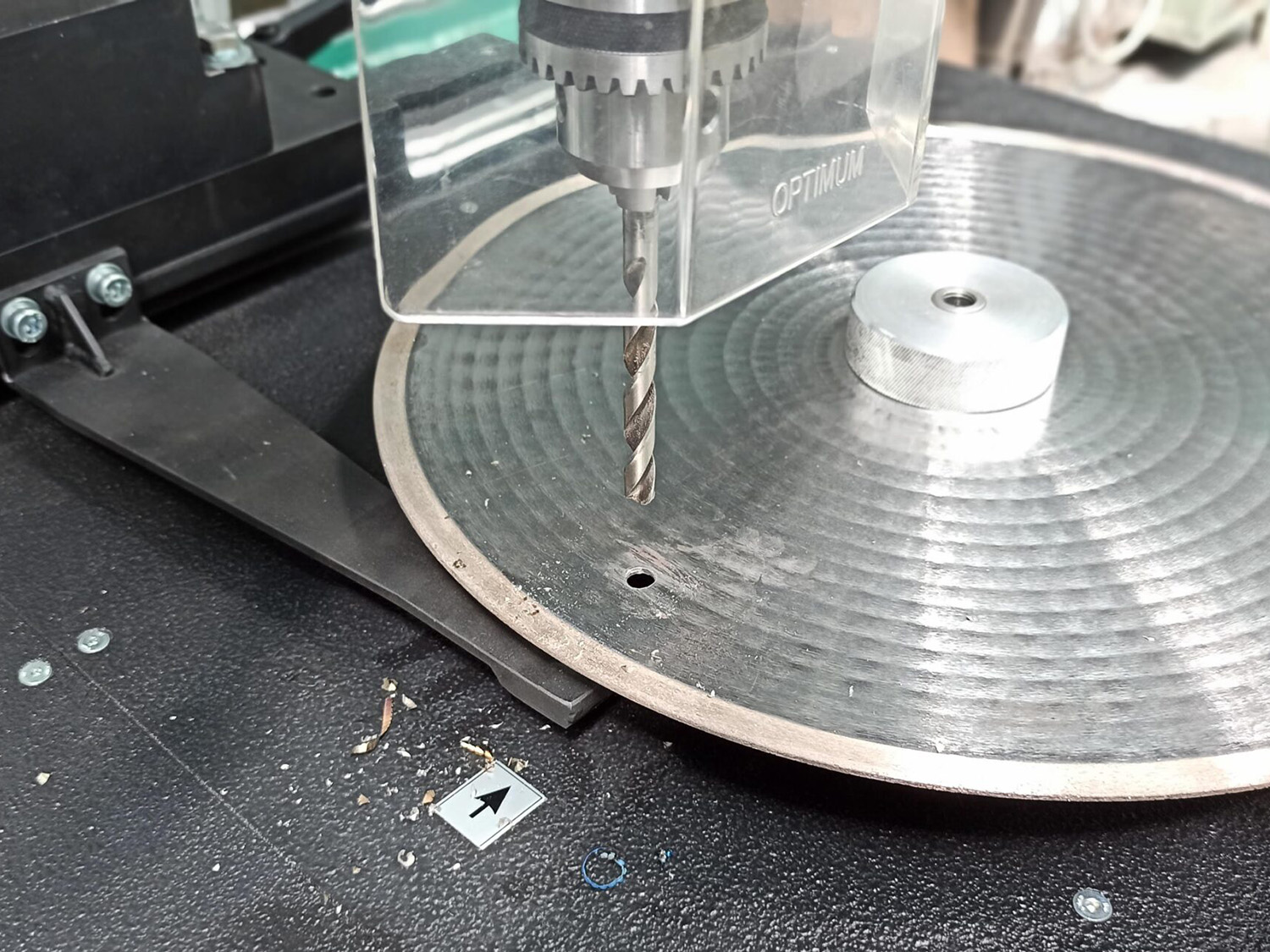

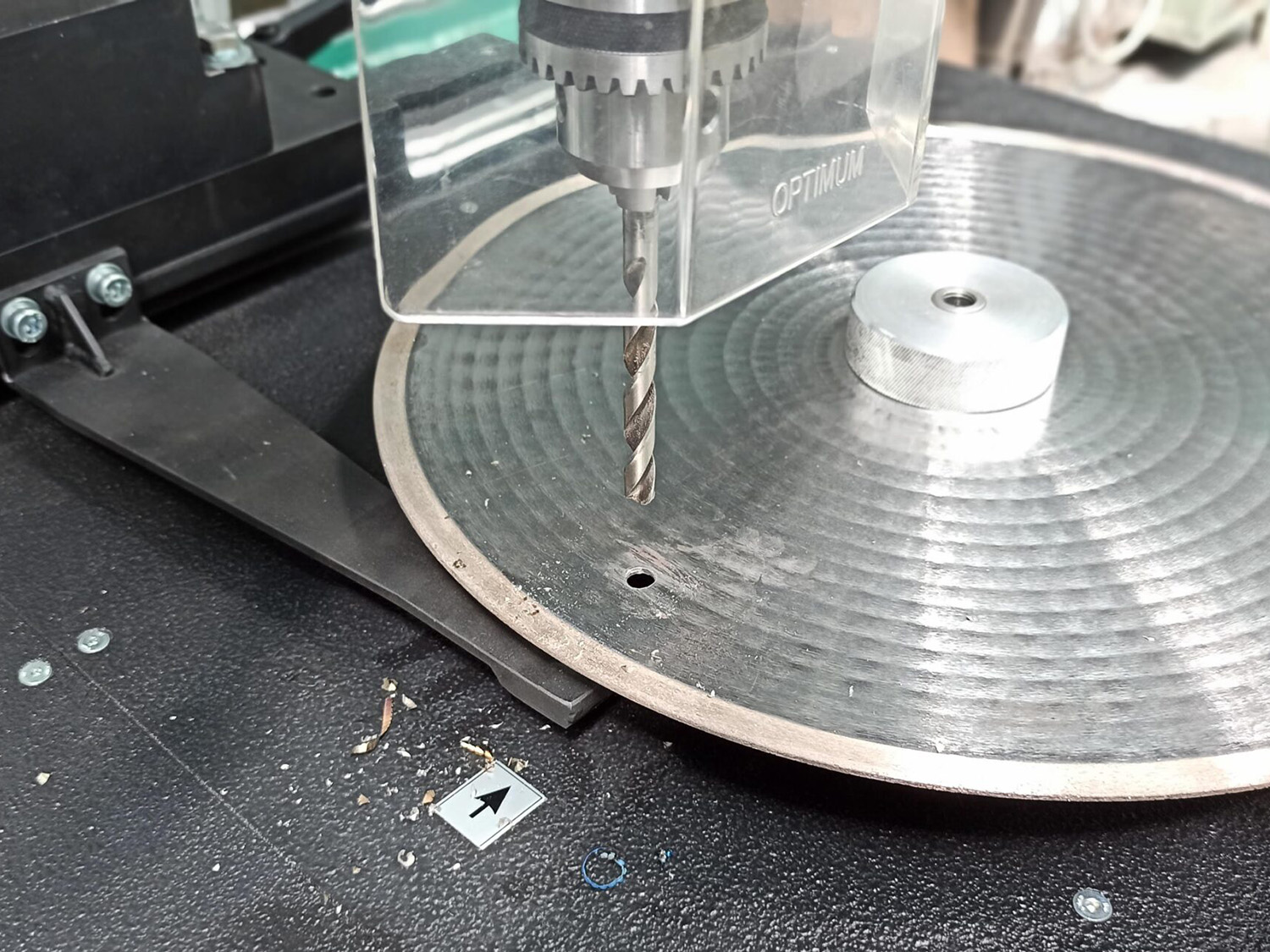

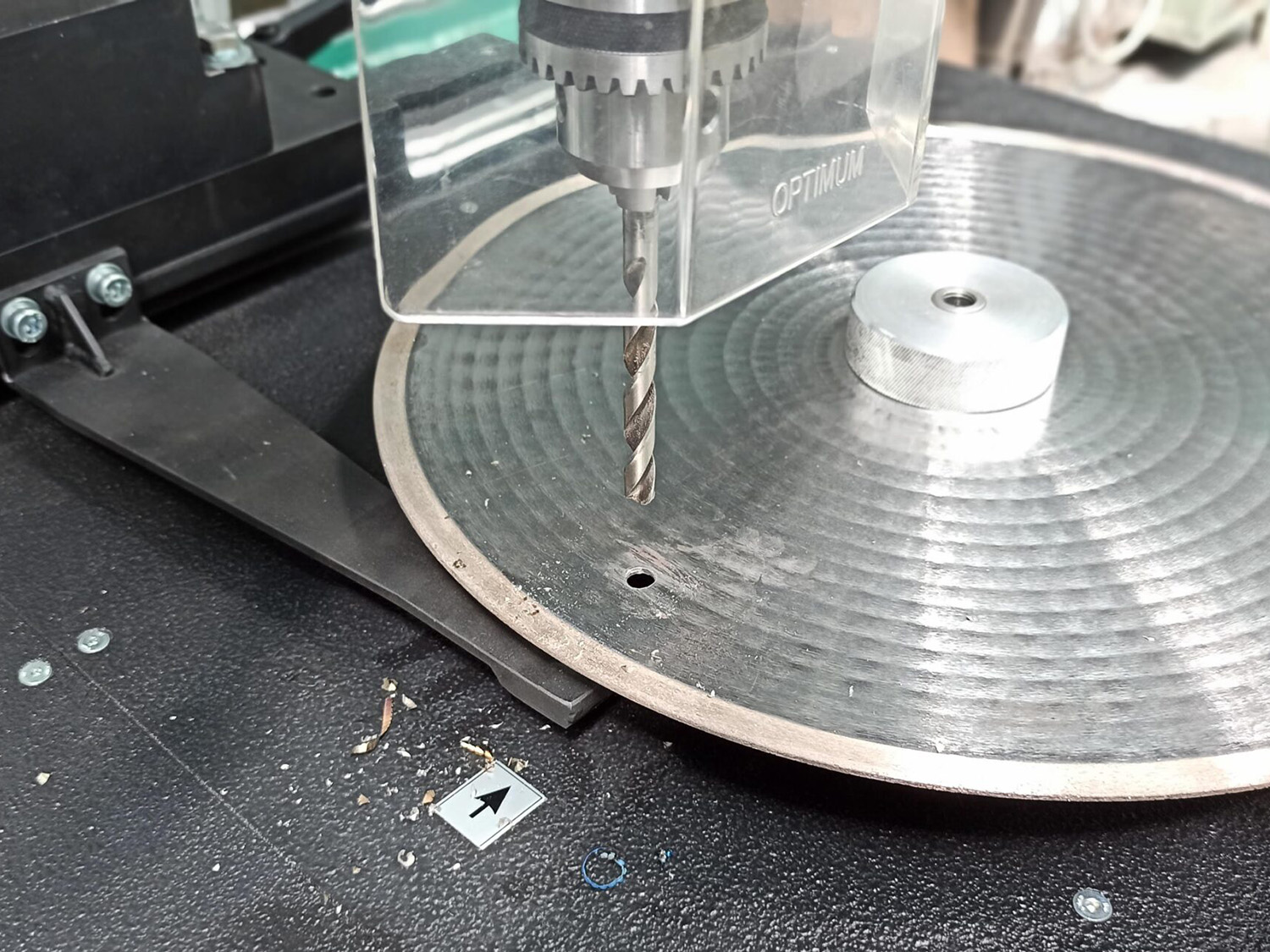

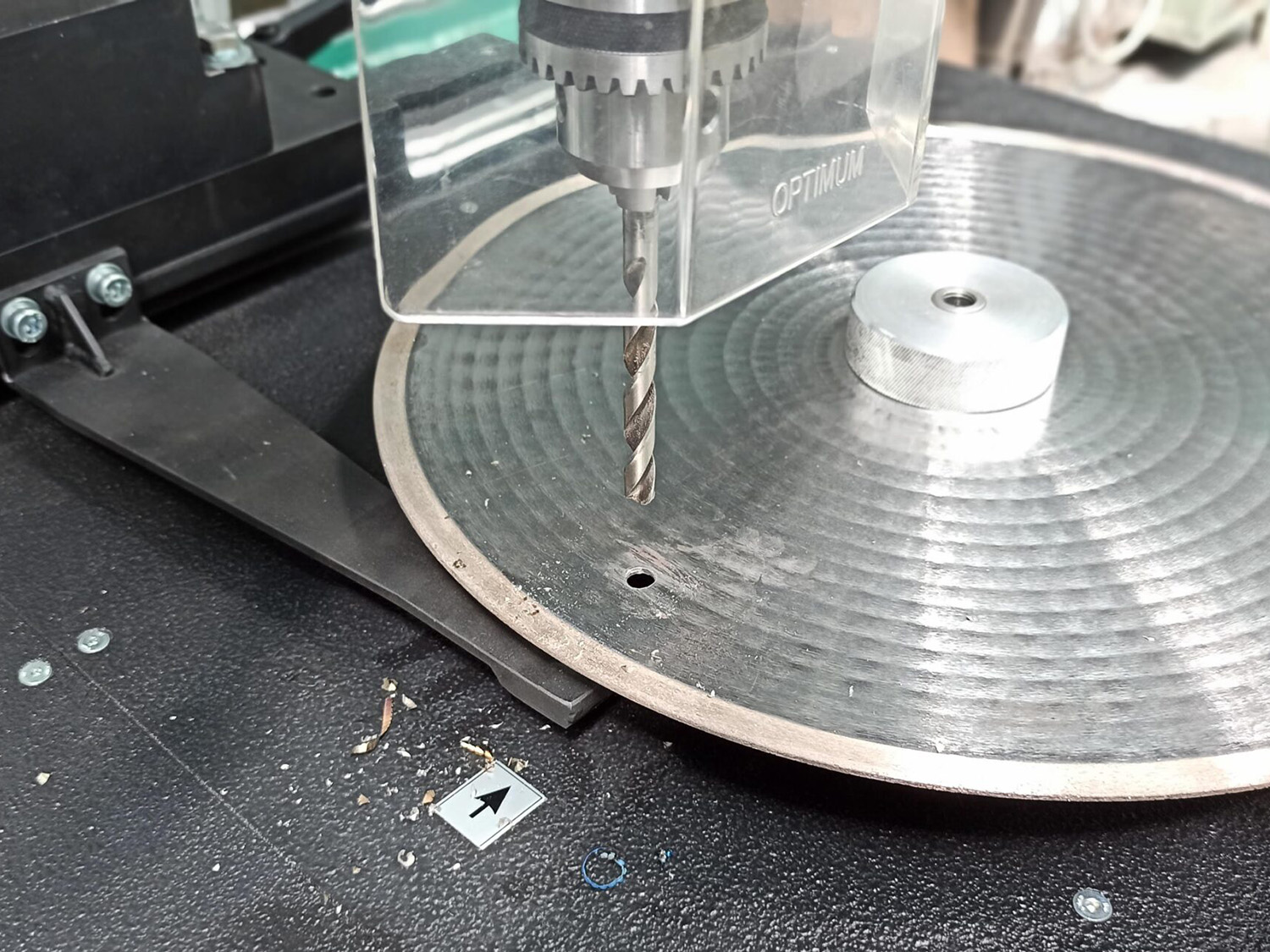

Balancing machines of this series have a vertical axis of rotation, which allows quick replacement of the part, and also provides convenient access to the unbalance elimination zone without removing the part from the machine. It can be used in the conditions of serial, small-scale and single production (depending on the configuration).

Support for rotors up to 250mm diameter and 150mm height within 10kg weight capacity provides substantial small component range. The envelope specifications accommodate diverse lightweight disk-type precision and small industrial components.

Design specifically optimized for diverse lightweight disk-type rotors including precision components, small cutting tools, and specialized discs. The optimization ensures compatibility with components lacking traditional bearing surfaces in compact applications.

Specialized capability for small pulleys, fan impellers, and precision cutting tools requiring high accuracy. The design accommodates challenging small geometries while maintaining measurement precision in space-efficient configuration.

Design flexibility enables balancing of small pump impellers, separator discs, and precision couplings across diverse small-scale applications. The versatile configuration maintains accuracy across varied small component types.

Full production cycle manufacturing enables custom machine configurations differing from standard specifications for small component applications. This capability accommodates unique precision application requirements while maintaining compact design integrity.

Design features optimized for efficient operation in serial, small-scale, and single production environments with lightweight components. The optimization provides operational flexibility across diverse small manufacturing scenarios while maintaining consistent precision performance.

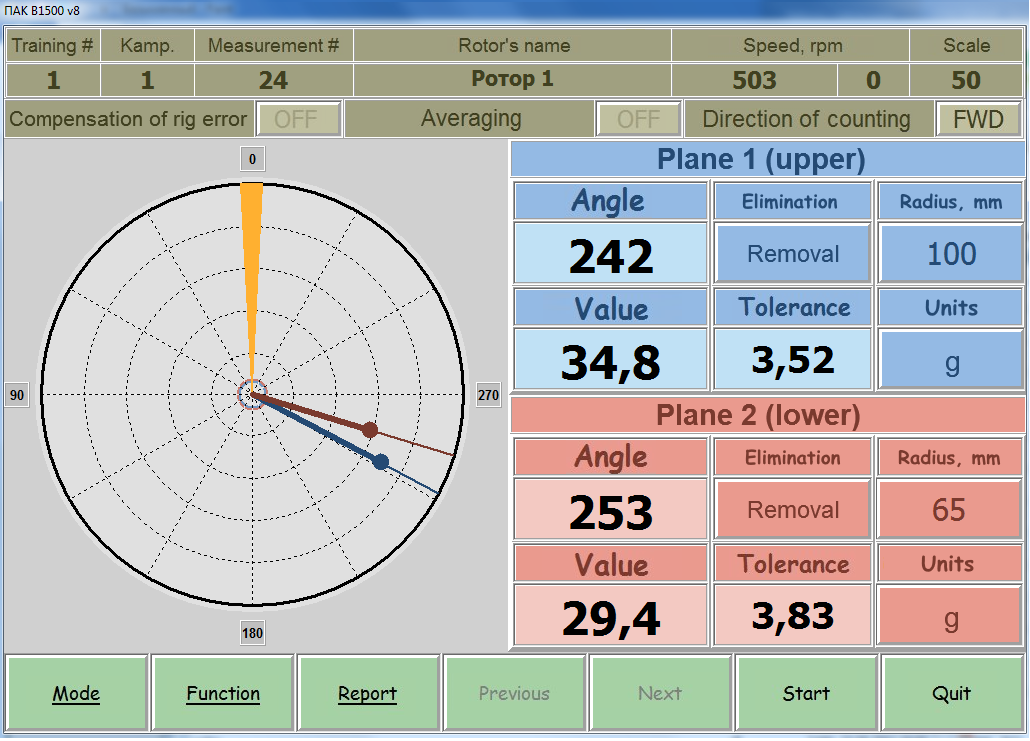

The PAK-1V unbalance measuring unit is a 2-plane measuring balancing system for balancing disc-type rotors on vertical balancing machines. It can perform static (single-plane) balancing in dynamic mode on a two-plane balancing machine.

Based on an industrial fanless computer with a touchscreen and a multi-channel measuring unit, the system ensures reliability and a long service life, even under intensive use. The PAK-1V utilizes a universal measuring path and modern component base, allowing for equally high accuracy when working with all types of rotors.

Its intuitive interface, self-calibration capability, and automation of key operations make the complex a convenient tool for both experienced specialists and novice beginners.

|

Parameter |

Value |

|---|---|

|

Balancing rotors weight range, kg |

0.1 – 10 |

|

Maximum rotor diameter (over the bed), mm |

250 |

|

Maximum rotor height, mm |

150 |

|

Machine type |

Hard-bearing |

|

Minimal achievable residual specific unbalance, gmm/kg |

4 |

|

Rotor rotation speed range, rpm |

300 – 1500 |

|

Number of measured rotor correction planes |

1 & 2 |

|

Electric motor power, kW |

1 |

|

Power supply parameters |

400V ± 10%, 3 Ph, 50Hz ± 1 |

|

Balancing system |

PAK-1V |

|

Overall machine dimensions (length x width x height), mm |

1600 x 1100 x 1500 |

|

Machine weight, kg |

450 |

Leave a request and our manager will contact you to answer questions via your preferred messenger.