Preventive Maintenance

Driveshaft inspection should be performed as part of your regular maintenance. Normal vehicle maintenance and recognition of component discrepancies are necessary to prevent serious mechanical problems and avoid driver discomfort. Failure to perform normal maintenance may also void the vehicle warranty.

Inspection of the driveshaft at the service

Inspection of the driveshaft at the service should be made in the presence of the client. It is important, because you can immediately focus his attention on the detected defects, while eliminating a lot of unnecessary questions.

Routine inspection steps

- Check the output and input end yokes for looseness.

- Check for excessive radial looseness of output/input shaft.

- Check for looseness across ends of u-joint.

- Check the slip spline for excessive radial movement.

- Check the shaft for damage, bent tubing, or missing balance weights.

- Check for a loose or missing slip yoke plug.

1. Driveshaft flange failure

Wear of the seating surfaces

Main causes:

- Loose bolted connection

- Fracture of the seating surface when installing or removing the driveshaft

- Foreign body between flanges during operation or repair

- Driveshaft vibration

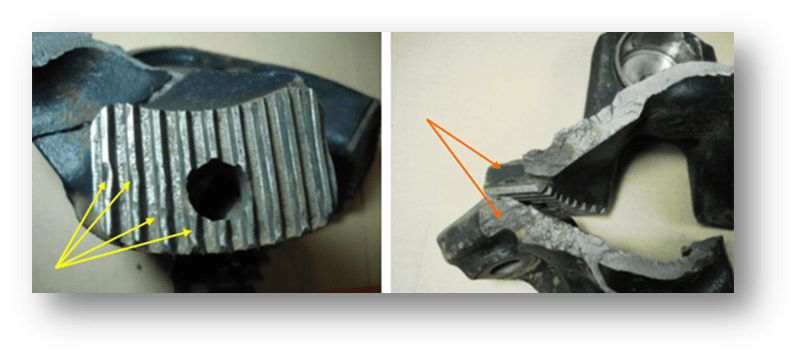

2. Driveshaft cross failure

Backlashes between the cross and forks

Main causes:

- Wear of the cup hole

- Excessive shock loads

- Driveshaft vibration

- Aggressive driving style

Oil and rust spots on the crosshead

Main causes:

- Wear of the sealing dust cap

- Water in the cup

Color change of the crossbody cup

Main causes:

- Lack of lubricant

- Wear of the sealing dust cap

- Dirt entering the cup

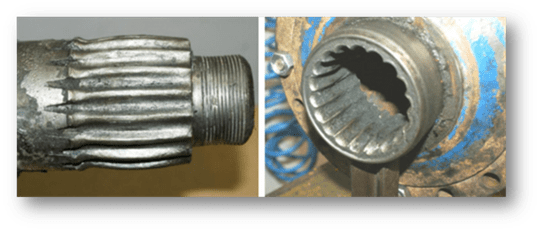

3. Spline joint

Slotted joint backlash

Main causes:

- Natural wear and tear of the splined joint

- Metal fatigue

- Driveshaft vibration

- Wear of rubber cover

- Lack of lubrication

- Dirt between splines

Wear and tear of the rilsan coating

Main causes:

- Overheating of the coating

- Material fatigue

- Dust cap wear

- Lack of grease

- Natural wear

4. Driveshaft outboard bearing failure

Cracks in the rubber bearing

Main causes:

- Material fatigue

- Increased driveshaft vibration

- Bearing wear

Wear of the bearing seating surface

Main causes:

- Driveshaft vibration

- Bearing wear

- Bearing slippage

- Dirt entering between bearing seating surface and bearing

Bearing wear

Main causes:

- Poor quality bearing

- Metal fatigue

- Excessive vibration

- Dirt inside the bearing

Change in the stiffness of the rubber support

Main causes:

- Material fatigue

- Low operating temperatures

5. Driveshaft tube failure

Pipe deflection

Main causes:

- Material fatigue

- Increased driveshaft vibration

- Bearing wear

Cracks in the tube

Main causes:

- Metal defect

- Welding seam defect

- Excessive vibration

- Intense stress

Dent in the tube

Main causes:

- Radial impact

- Deformation of the pipe when removing/installing or repairing the driveshaft

- Incorrectly calculated pipe wall thickness

Afterword

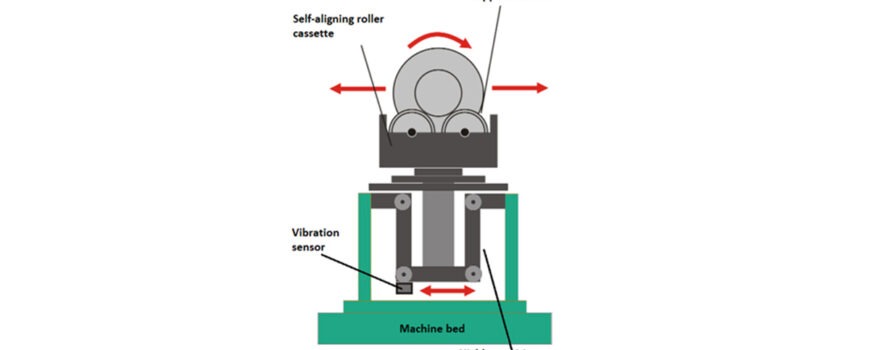

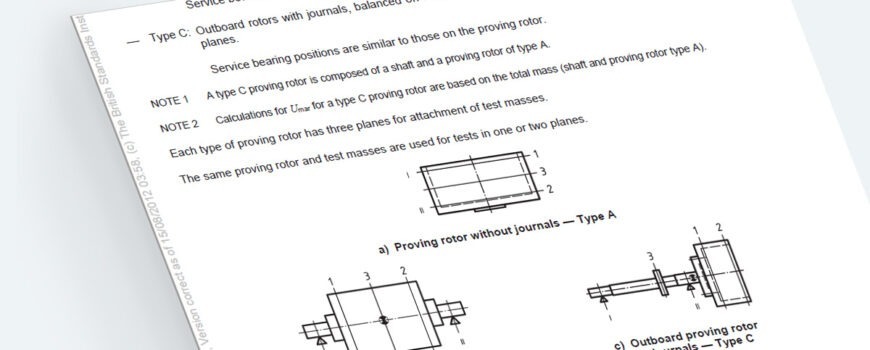

Note how common excessive vibration is on this list. Usually, it’s caused by a lack of balance or poor balance.

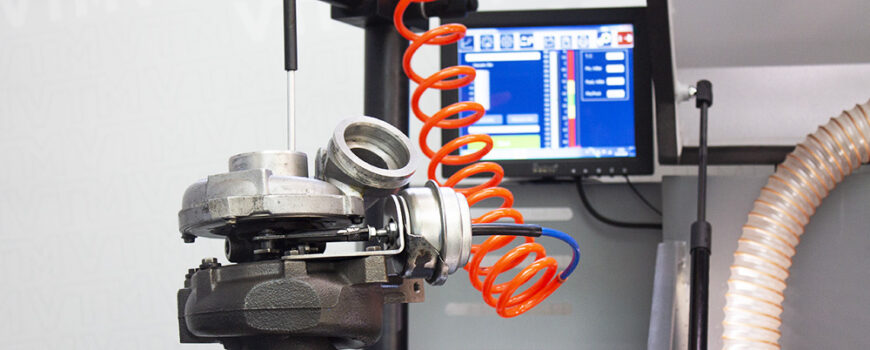

This brings our article to an end. If you are interested in equipment for the driveshaft repair or balancing machine to eliminate vibration, you can contact our experts for advice. They will be happy to offer you the best set of equipment for you. Thank you for your attention and good luck in your work.