|

Balance Grade, mm/s |

Machinery Examples |

|---|---|

|

G 4000 |

Crankshaft drives for large, slow marine diesel engines (piston speed below 9 m/s), inherently unbalanced |

|

G 1600 |

Crankshaft drives for large, slow marine diesel engines (piston speed below 9 m/s), inherently balanced |

|

G 630 |

Crankshaft drives, inherently unbalanced, elastically mounted |

|

G 250 |

Crankshaft drives, inherently unbalanced, rigidly mounted |

|

G 100 |

Complete reciprocating engines for cars, trucks and locomotives |

|

G 40 |

Cars: wheels, wheel rims, wheel sets, drive shafts |

|

G 16 |

Agricultural machinery |

|

G 6,3 |

Aircraft gas turbines |

|

G 2,5 |

Compressors |

|

G 1 |

Audio and video drives |

|

G 0,4 |

Gyroscopes |

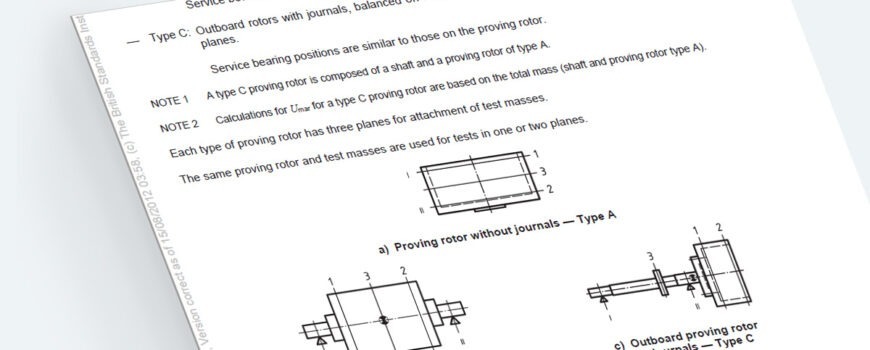

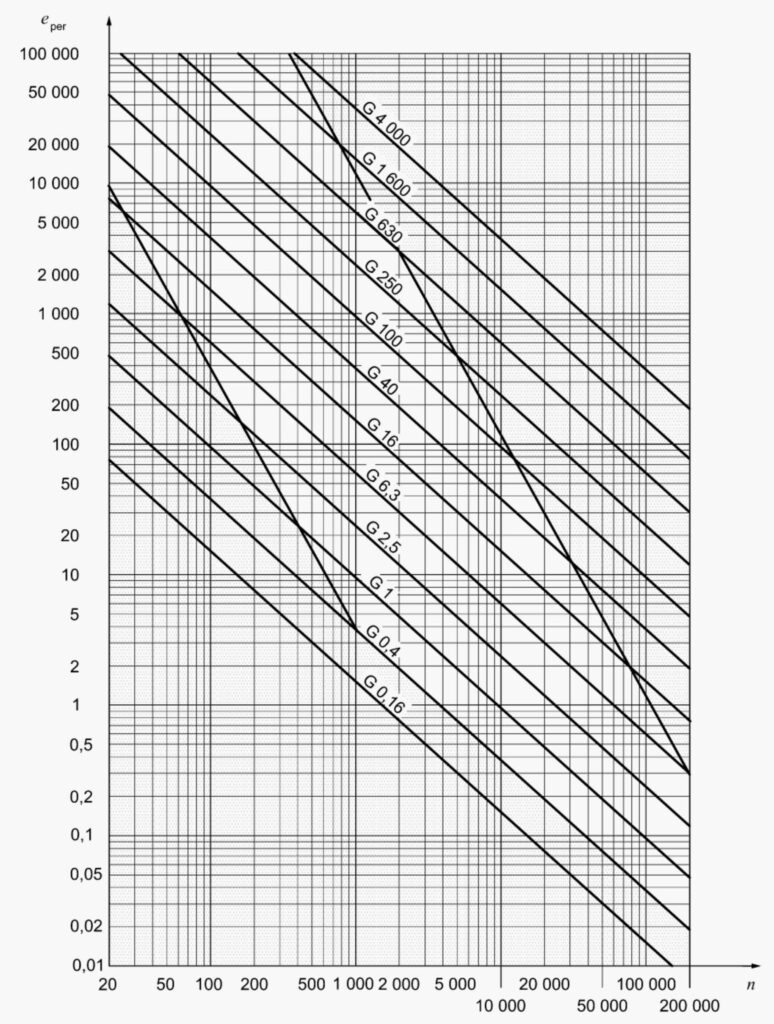

Guidance for balance quality grades for rotors with rigid behavior

Permissible residual specific unbalance based on balance grade G and service speed, n