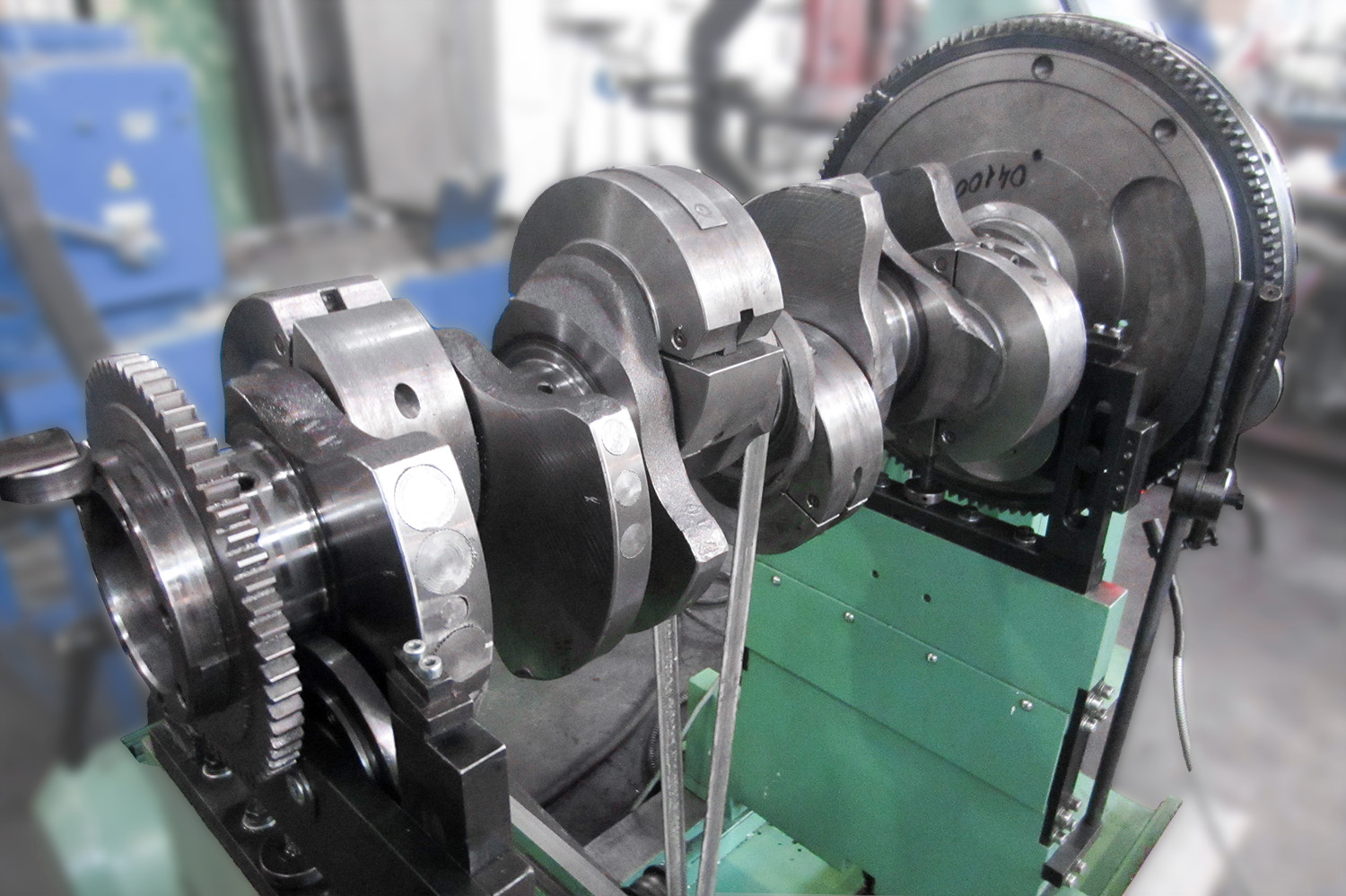

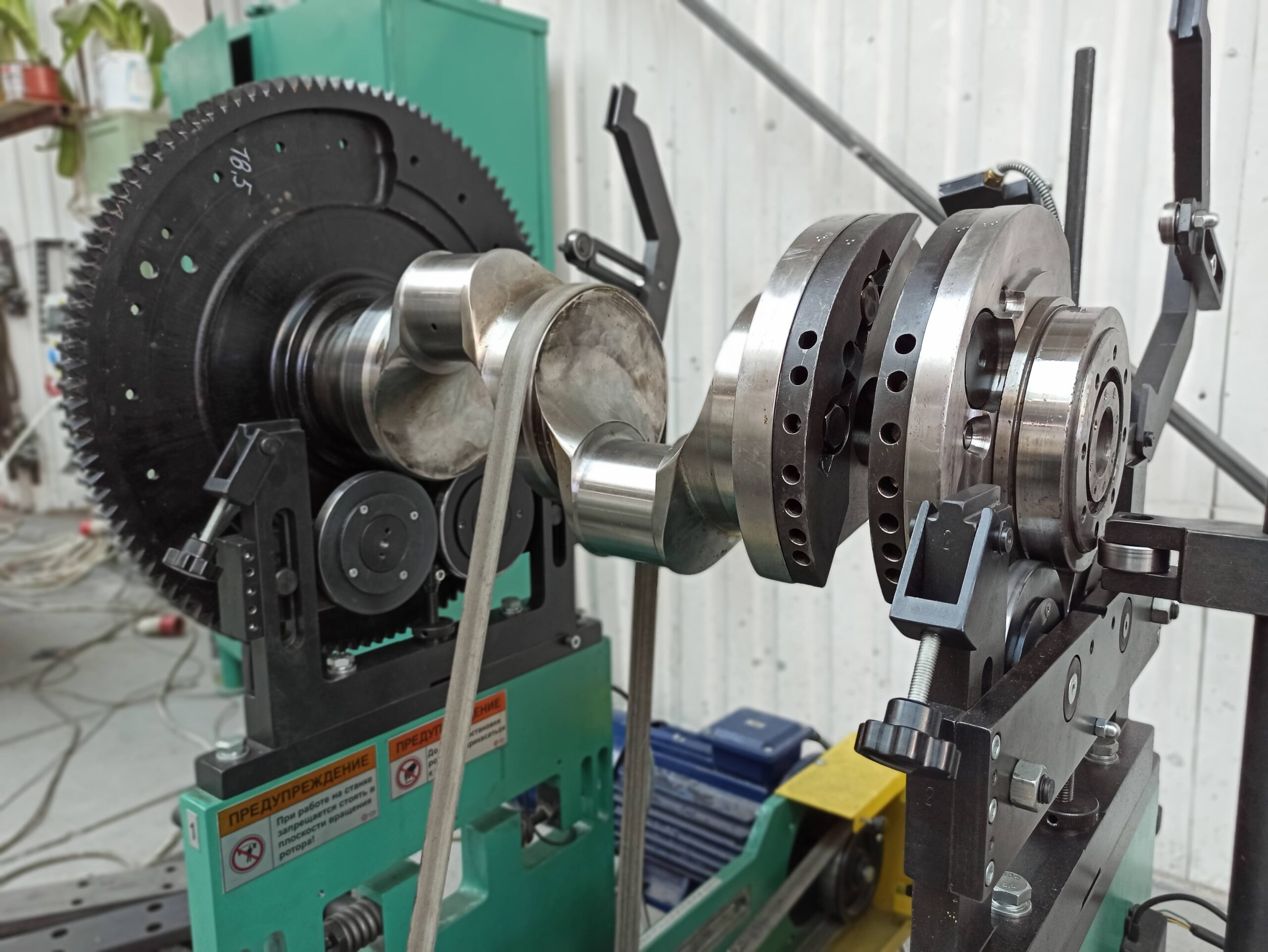

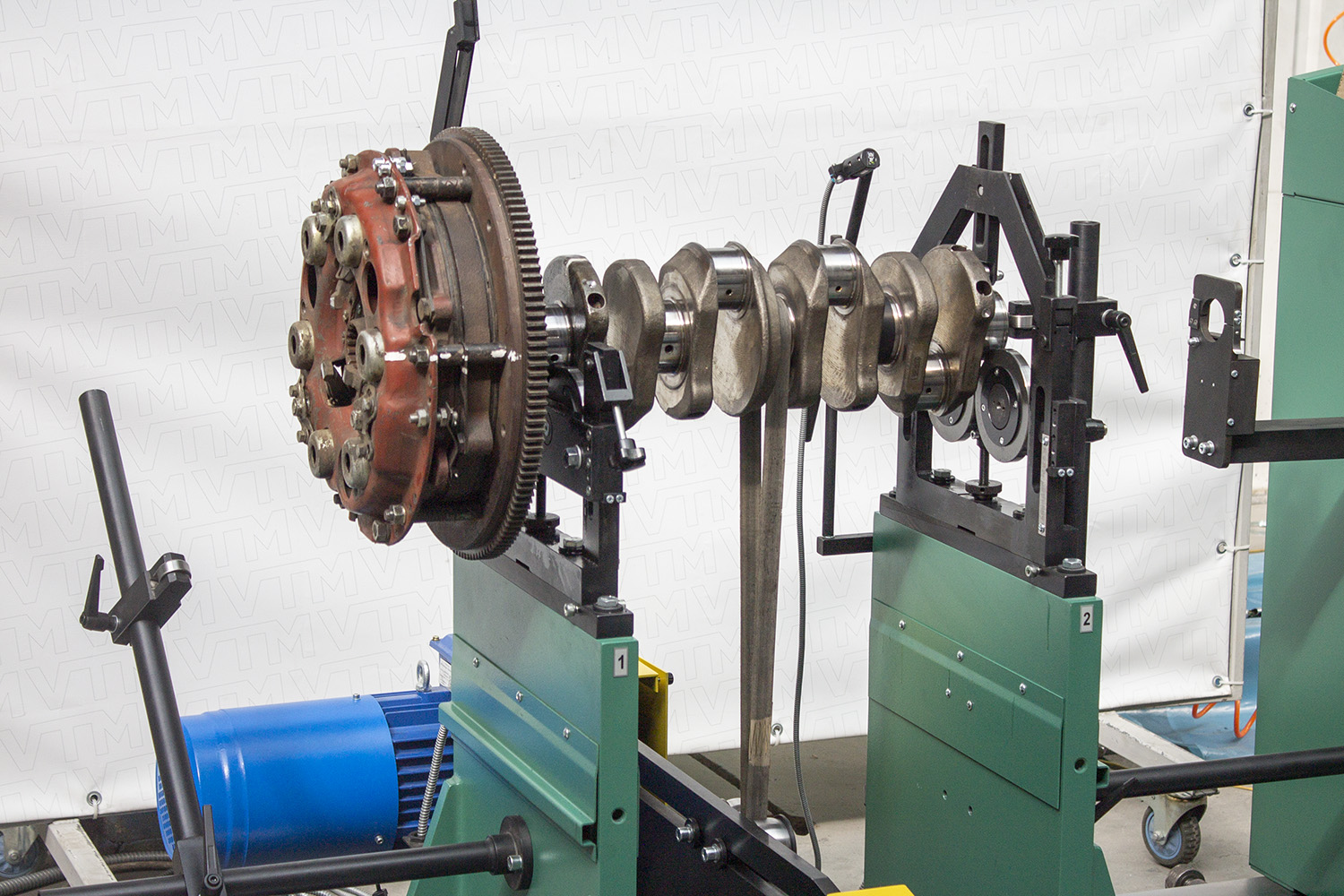

Crankshaft balancing

Our dynamic balancing machine is the perfect solution for service centers, engine rebuilders, and performance workshops working with passenger cars, racing engines, and heavy-duty truck components.

This series of machines can be used to balance such parts

Machines for balancing crankshafts up to 300 kg, including:

-

Crankshafts of 4 and 6 cylinder in-line engines

-

Flat crankshafts of 4 and 6 cylinder flat engines

-

V6, V8, V10 and V12 crankshafts with bobweights on rod pins

-

Inline 1, 2, 3 and 5 cylinder crankshafts with bobweights on rod pins

Difficulties encountered by services when balancing crankshafts

Thanks to its sophisticated design and intelligent measurement system, the 9D715US solves the typical problems services encounter when balancing crankshafts.

Other options required for crankshaft balancing

-

Vertical drilling unit for on-machine correction (on linear guide rails)

-

Recalculation of unbalanced mass into drilling depth, taking into account the drill diameter

-

Conversion of imbalance into other correction planes (between counterweights)

-

Axial stops centre the crankshaft during rotation

-

Balancing V-shaped crankshafts with bobweights on rod pins is no problem for our machines

-

We can supply sets of bobweights of various sizes

Find out which products fit your requirements

VTM Group delivers balancing solutions for your parts — not just machines

We analyze your drawings, calculating the required balancing accuracy and process productivity before you purchase the equipment.

Our engineers select the optimal standard model or propose a modified or special-purpose machine designed for your specific part.

We design and manufacture all necessary fixtures and adapters to fit your complete product range.

We provide a step-by-step methodology and practical recommendations tailored specifically to your products.

We train your team at a convenient time, considering your production specifics.

We perform complete installation, startup, and calibration at your facility, ensuring you can begin operations without delay.