DBST-10

Low-speed turbocharger core balancing machine, cartridge testing, oil leak detection

Maximal weight, kg

Maximum compressor wheel diameter, mm

Compact and precise balancing for small workshops

The low-speed cartridge balancer satisfies the needs of turbocharger repair workshops. It is multifunctional and versatile, so it is suitable for a large number of common turbochargers of trucks and cars. It is also suitable for repairing turbochargers of special vehicles and even some boats.

The machine is used for :

- Balancing technological imbalance after the cartridge assembly.

- Checking for oil leakage.

- Running-in of the assembled cartridge at safe speeds.

- Checking the quality of the cartridge assembly in bench mode.

- The mounting system is universal and allows to work with any type of turbine, including those with bottom oil supply or unusual design;

- A hydraulic pump creates an “oil wedge” in the gaps between the turbocharger parts, ensuring that they remain intact as the shaft rotates;

- Oil temperature and pressure is regulated to recreate the operating conditions of any turbocharger and to use inexpensive synthetic oils;

- Optimal oil station volume allows for quick warm-up and relatively infrequent oil changes, saving time and money;

- Fine and coarse filters prevent chips and micro-particles from getting into the cartridge, prolonging the life of the oil and protecting the cartridge parts from wear and tear;

- The design of the enclosure gives free access to any unit or component of the booth, making maintenance and repair easier;

- Good working area illumination allows a good assessment of the turbocharger condition when checking for oil leaks and balancing, as well as facilitating set-up;

- Transparent reinforced hydraulic hose and viewing window allow the oil condition to be assessed for timely oil replacement;

- Reliable and readily available components are used. No problem with finding accessories when repairing the stand;

- Calibration of the balancing system takes less than 2 minutes and is carried out by the operator of the test bench;

- 20 memory slots to save the settings of the stand saves time for adjustment when working with the same type of cartridges.

CHRA-Specific Post-Assembly Balancing

- 15 kg maximum turbocharger capacity – Accommodates turbochargers up to 15 kg weight and 280 mm diameter with rotor wheel spacing of 50-230 mm, covering the majority of automotive and light commercial turbocharger applications. This capacity range ensures compatibility with standard turbocharger service requirements.

- Low-speed final balancing specialization – Engineered specifically for post-assembly balancing of turbocharger rotor assemblies within their own housings, eliminating “technological” unbalance that occurs during cartridge assembly processes. This final balancing stage ensures optimal turbocharger performance after all components are integrated into their operational configuration.

- External element correction capability – Designed for unbalance correction using only externally accessible rotor elements including wheel nuts and turbine shaft bosses after housing assembly. This approach enables comprehensive balancing without disassembly while accommodating the limited access typical of completed turbocharger cartridges.

- 0.4 g·mm/kg ultra-precision measurement – Achieves exceptional balancing accuracy specifically calibrated for turbocharger CHRA applications where minute unbalances significantly impact performance. This precision level ensures optimal turbocharger operation and extended bearing life in demanding automotive applications.

- Soft torsion bar suspension – High-sensitivity machine design utilizing soft torsion bar suspension system for enhanced measurement capability at low operational speeds up to 20,000 rpm. The specialized suspension isolates external vibrations while maintaining structural integrity during turbocharger cartridge testing.

- Air-powered rotation system – Pneumatic system operating at 0.6 MPa provides clean, reliable shaft rotation without contamination concerns typical of mechanical drive systems. The air drive eliminates potential oil contamination while ensuring smooth, controlled rotation for accurate measurement.

- Cabinet-type protective enclosure – Working area enclosed by cabinet-style casing with integrated local lighting ensures operator safety during high-speed turbocharger testing. The protective enclosure contains potential component separation while providing optimal visibility for precision work.

Advanced Hydraulic Simulation System

- Oil wedge recreation technology – Integrated hydraulic system with 0.5 MPa operating pressure creates protective “oil wedge” between turbocharger components, simulating actual operating conditions during balancing. This technology enables realistic testing while protecting valuable components from contact damage during rotation.

- Triple-stage oil purification system – Hydraulic oil undergoes three levels of purification ensuring turbocharger component safety and enabling unbalance correction without cartridge removal from the machine. The comprehensive purification system maintains oil cleanliness critical for accurate simulation of operational lubrication conditions.

- 9-liter oil station with thermal control – Large-capacity oil tank reduces maintenance frequency while thermal relay and thermocouple system provides precise temperature regulation. The substantial oil volume ensures consistent hydraulic performance with viewing window for oil condition monitoring throughout extended balancing sessions.

- Oil leak detection capability – Integrated system enables post-assembly oil leak testing of turbocharger cartridges, combining balancing and quality control functions in a single operation. This dual capability streamlines turbocharger quality assurance while reducing handling and setup time.

Universal CHRA Compatibility System

- Comprehensive cartridge mounting capability – Universal mounting system accommodates virtually all modern turbocharger manufacturers using supplied equipment, establishing the machine as highly versatile for diverse turbocharger service operations. The universal compatibility eliminates the need for specialized fixtures for different turbocharger brands and models.

- Complex design accommodation – Vibrating table features specialized mounting holes for turbochargers with complex configurations including VW-style “paw” mounting systems. This accommodation ensures compatibility with European and specialty turbocharger designs requiring non-standard mounting approaches.

- Bottom oil supply adapters – Special adapters enable installation of turbochargers with bottom oil supply configurations, expanding compatibility range for various turbocharger designs. The adapter system provides flexibility while maintaining measurement accuracy and hydraulic protection levels.

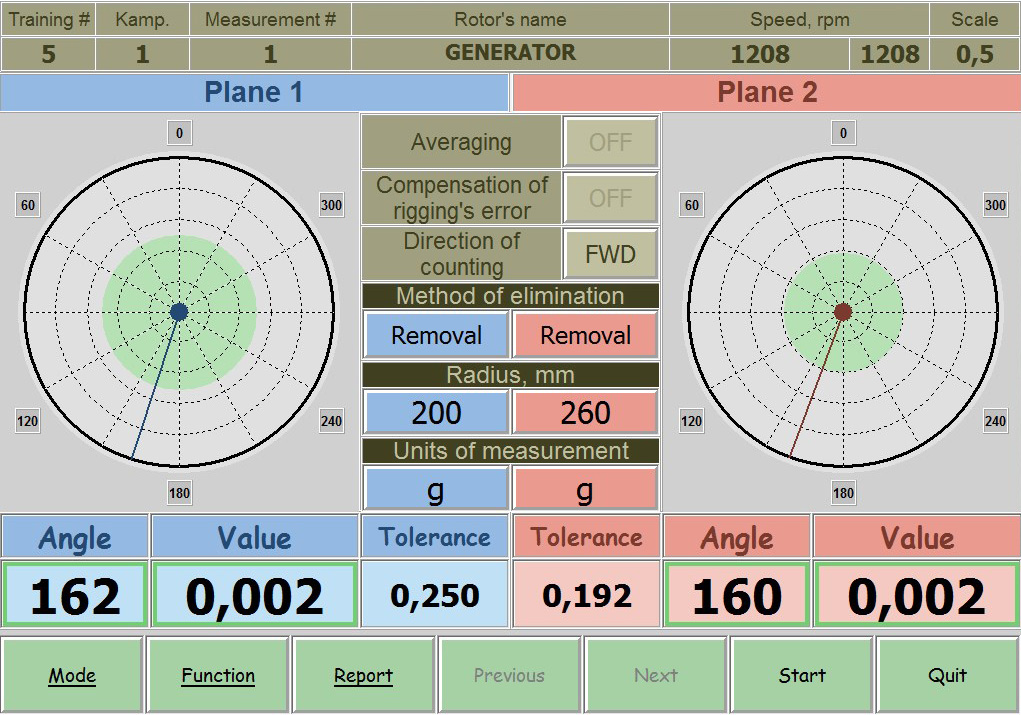

The PAK-1 unbalance measuring unit represents the latest generation of measuring complexes for dynamic balancing, combining high precision, stability, and ease of use. It’s designed to tackle a wide range of rotor balancing tasks, from simple to the most complex, requiring precise measurements.

Based on an industrial fanless computer with a touchscreen and a multi-channel measuring unit, the system ensures reliability and a long service life, even under intensive use. The PAK-1 utilizes a universal measuring path and modern component base, allowing for equally high accuracy when working with all types of rotors.

Its intuitive interface, self-calibration capability, and automation of key operations make the complex a convenient tool for both experienced specialists and beginners.

Features of the PAK-1 System:

- High-precision dynamic balancing for rotors of any configuration.

- Industrial fanless PC with touchscreen and multi-channel measuring unit.

- Setup using trial runs with calibration weights on production rotors.

- Self-calibration by the operator, eliminating annual service adjustment costs.

- Calculation of permissible unbalance values, even without technical documentation.

- Determination of control weight mass to simplify setup for a specific rotor.

- Real-time display of unbalance magnitude and angular position, including “highlighting” of the correction zone.

- Automatic measurement start upon reaching a set speed and automatic stop after cycle completion.

- Display of unbalance magnitude in grams, gmm, gcm, gmm/kg.

- Vector and exponential averaging for working with moving elements and in noisy conditions.

- Additional functions that significantly simplify the balancing process and expand the technological capabilities of the balancing machine.

- Generation and printing of balancing reports directly from the system.

- USB ports and Ethernet interfaces for connecting a printer, data storage, and integration into a local network.

|

Parameter |

Value |

|---|---|

|

Maximum turbocharger weight, kg |

15 |

|

Maximum turbocharger diameter, mm |

80 |

|

Distance between the centers of turbocharger rotor wheels, mm |

50 – 230 |

|

Maximum achievable rotor rotation frequency, rpm |

10000 |

|

Minimal achievable residual specific unbalance, gmm/kg |

0.4 |

|

Nominal operating pressure of the lubrication system, MPa |

0.5 |

|

Required pneumatic system pressure, MPa |

0.6 |

|

Power input, kW |

1.5 |

|

Power supply parameters |

230V ± 10%, 1 Ph, 50Hz ± 1 |

|

Balancing system |

PAK-1 |

|

Overall machine dimensions (length x width x height), mm |

900 x 520 x 1270 |

|

Machine weight, kg |

230 |

|

Requirements for foundation |

The machine is mounted on a standard hard floor in workshop |

- Oil tank with oil heating for 12 l – 1 pc.

- Adapter kit for installation of all types of turbines, including turbines with a lower oil supply – 1 set.

- Operations manual of the machine with acceptance test report and a schematic circuit diagram – 1 pc.

- Operations manual of balancing system with acceptance test report – 1 pc.

The package allows you to install the entire range of turbines from modern manufacturers.